8 ENGLISH

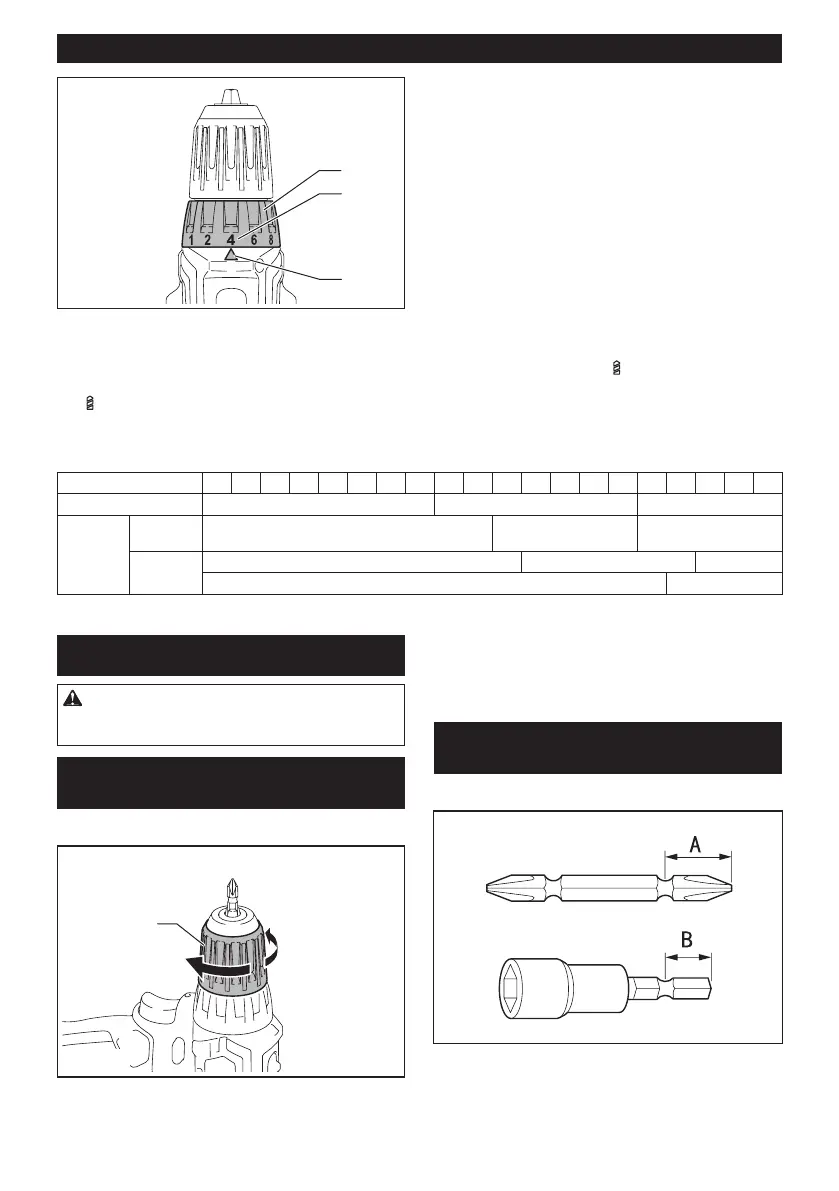

Adjusting the fastening torque

1

2

3

►1.Adjustingring2. Graduation 3. Arrow

Thefasteningtorquecanbeadjustedin21levelsbyturningtheadjustingring.Alignthegraduationswiththearrow

onthetoolbody.Youcangettheminimumfasteningtorqueat1andmaximumtorqueat

marking.

Theclutchwillslipatvarioustorquelevelswhensetatthenumber1to20.Theclutchdoesnotworkat

the marking.

Beforeactualoperation,driveatrialscrewintoyourmaterialorapieceofduplicatematerialtodeterminewhich

torquelevelisrequiredforaparticularapplication.

The following shows the rough guide of the relationship between the screw size and graduation.

Graduation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Machine screw M4 M5 M6

Wood

screw

Soft wood

(e.g. pine)

– ɸ3.5 x 22 ɸ4.1 x 38

Hard wood

(e.g. lauan)

– ɸ3.5 x 22 –

– ɸ4.1 x 38

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Installing or removing driver bit/

drill bit

For Model DF333D (optional accessory)

3

2

1

►1. Sleeve 2. Close 3. Open

Turn the sleeve counterclockwise to open the chuck

jaws.Placethedriverbit/drillbitinthechuckasfar

as it will go. Turn the sleeve clockwise to tighten the

chuck. To remove the driver bit/drill bit, turn the sleeve

counterclockwise.

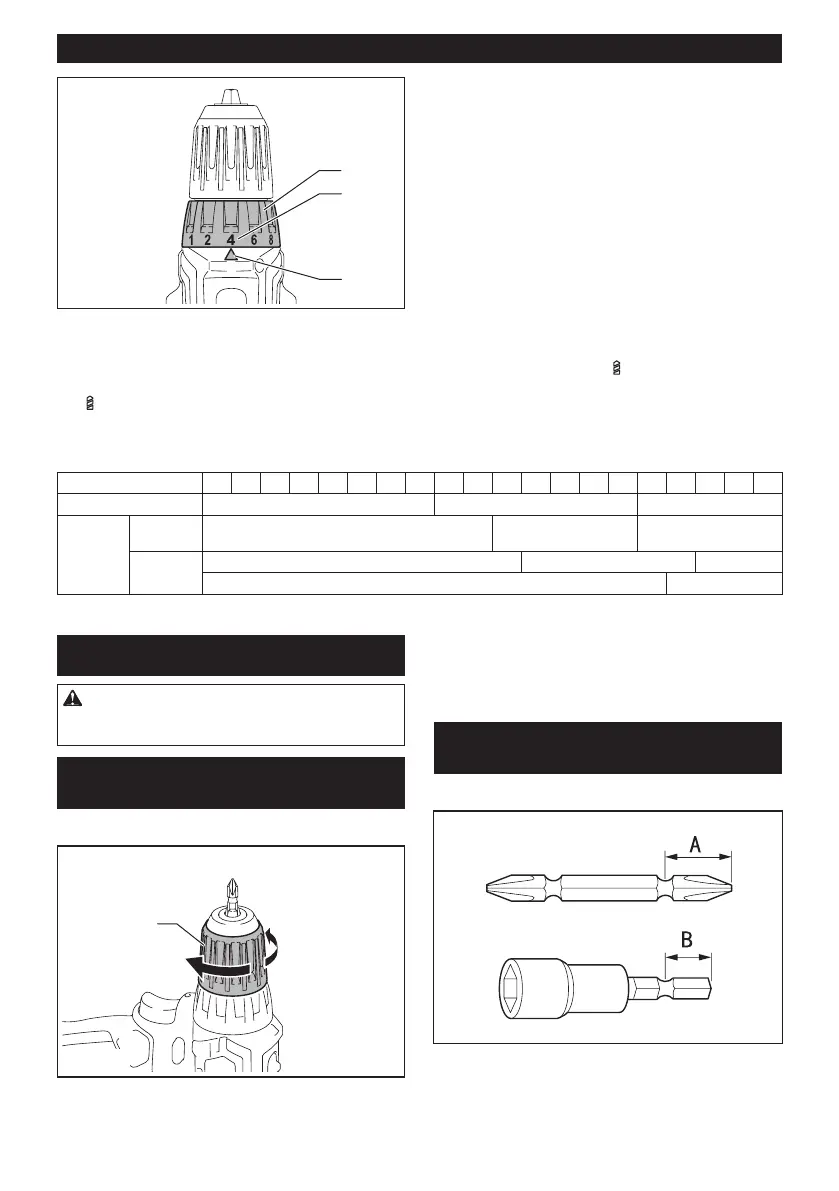

Installing or removing driver bit/

socket bit

For Model DF033D (optional accessory)

Useonlydriverbit/socketbitthathasinsertingportion

showninthegure.Donotuseanyotherdriverbit/

socket bit.

Loading...

Loading...