8

OPERATION

Driving operation

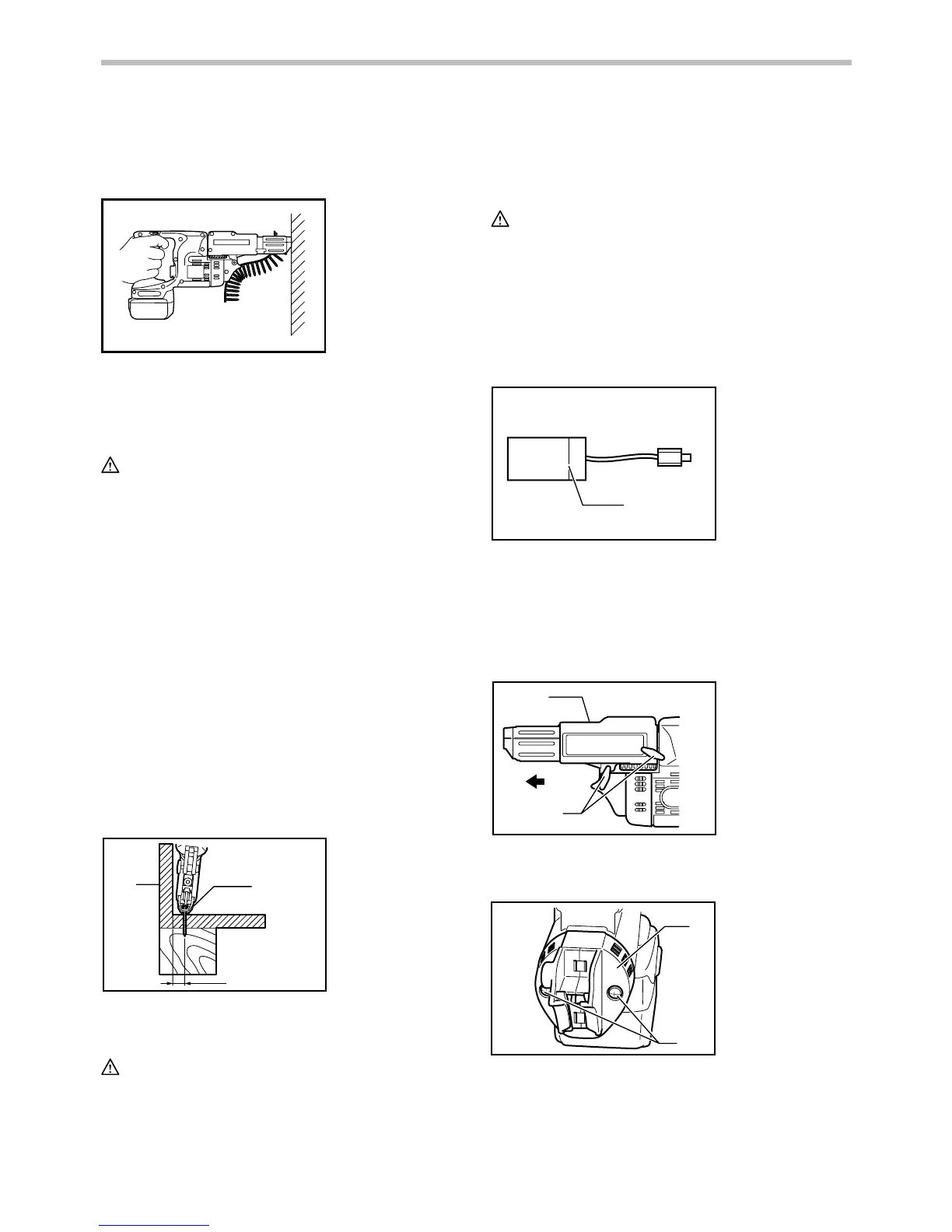

006811

Switch on the tool by pulling the switch trigger. Hold the

tool squarely and firmly up against the driving surface. A

screw will be automatically carried to the driving position

and fastened.

CAUTION:

• Always check the bit carefully for wear before

driving operations. Replace a worn bit or poor

fastening may result.

• Always hold the tool squarely against the driving

surface. Holding it at an angle may damage the

screw heads and cause wear on the bit. This may

also lead to poor fastening.

• Always keep the tool firmly against the driving

surface until the driving is over. Failure to do so

may cause insufficient fastening of screws.

• Be careful not to drive a screw onto another screw

already fastened.

• Do not operate the tool without screws. It will

damage the driving surface.

• If the feeder box does not work smoothly when

driving screws, spray car wax (spray type) on the

sliding surfaces. Never lubricate it.

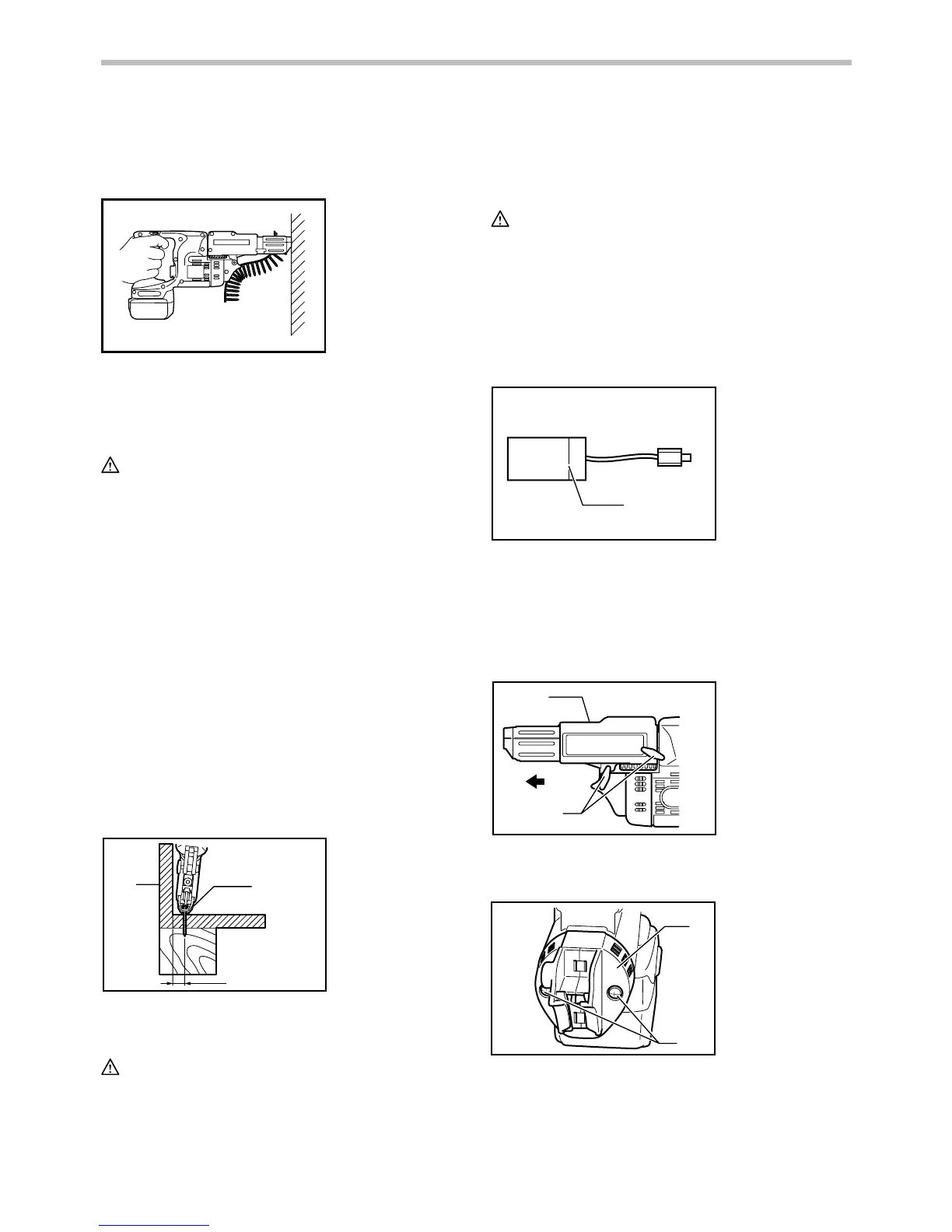

Driving in corner

15mm

1

2

006812

This tool can be used to drive at a position 15 mm away

from the wall as shown in the figure.

CAUTION:

• Driving at a position closer than 15 mm to the wall

or driving with the stopper base in contact with the

wall may damage the screw heads and cause wear

on the bit. This may also lead to poor fastening of

screws and malfunction of the tool.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may

result.

Replacing carbon brushes

1

006258

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Loosen the thumb screws which secure the casing. Pull

out the casing in the direction of the arrow.

1

2

006813

Use a screwdriver to remove two screws then remove

the front cover.

1

2

006815

Raise the arm part of the spring and then place it in the

recessed part of the housing with a slotted bit

screwdriver of slender shaft or the like.

1. Front cover

2. Screws

1. Casing

2. Thumb screws

1. Limit mark

1. Wall

2. Stopper base

Loading...

Loading...