8

Turn the sleeve counterclockwise to open the chuck jaws.

Place the bit in the chuck as far as it will go. Turn the

sleeve clockwise to tighten the chuck. To remove the bit,

turn the sleeve counterclockwise.

Installing bit holder

1

2

012708

Fit the bit holder into the protrusion at the tool foot on

either right or left side and secure it with a screw.

When not using the driver bit, keep it in the bit holders.

Bits 45 mm long can be kept there.

Adjustable depth rod

1

2

012712

The adjustable depth rod is used to drill holes of uniform

depth. Loosen the clamp screw, set to desired position,

then tighten the clamp screw.

Hook

1

2

3

012698

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool.

To install the hook, insert it into a groove in the tool

housing on either side and then secure it with a screw. To

remove, loosen the screw and then take it out.

OPERATION

012737

Hammer drilling operation

CAUTION:

• There is a tremendous and sudden twisting force

exerted on the tool/bit at the time of hole

break-through, when the hole becomes clogged

with chips and particles, or when striking reinforcing

rods embedded in the concrete. Always use the

side grip (auxiliary handle) and firmly hold the tool

by both side grip and switch handle during

operations. Failure to do so may result in the loss of

control of the tool and potentially severe injury.

First, slide the action mode change lever so that it points

to the

marking. The adjusting ring can be aligned in

any torque levels for this operation.

Be sure to use a tungsten-carbide tipped bit.

Position the bit at the desired location for the hole, then

pull the switch trigger. Do not force the tool. Light

pressure gives best results. Keep the tool in position and

prevent it from slipping away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at an

idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out

and normal drilling may be resumed.

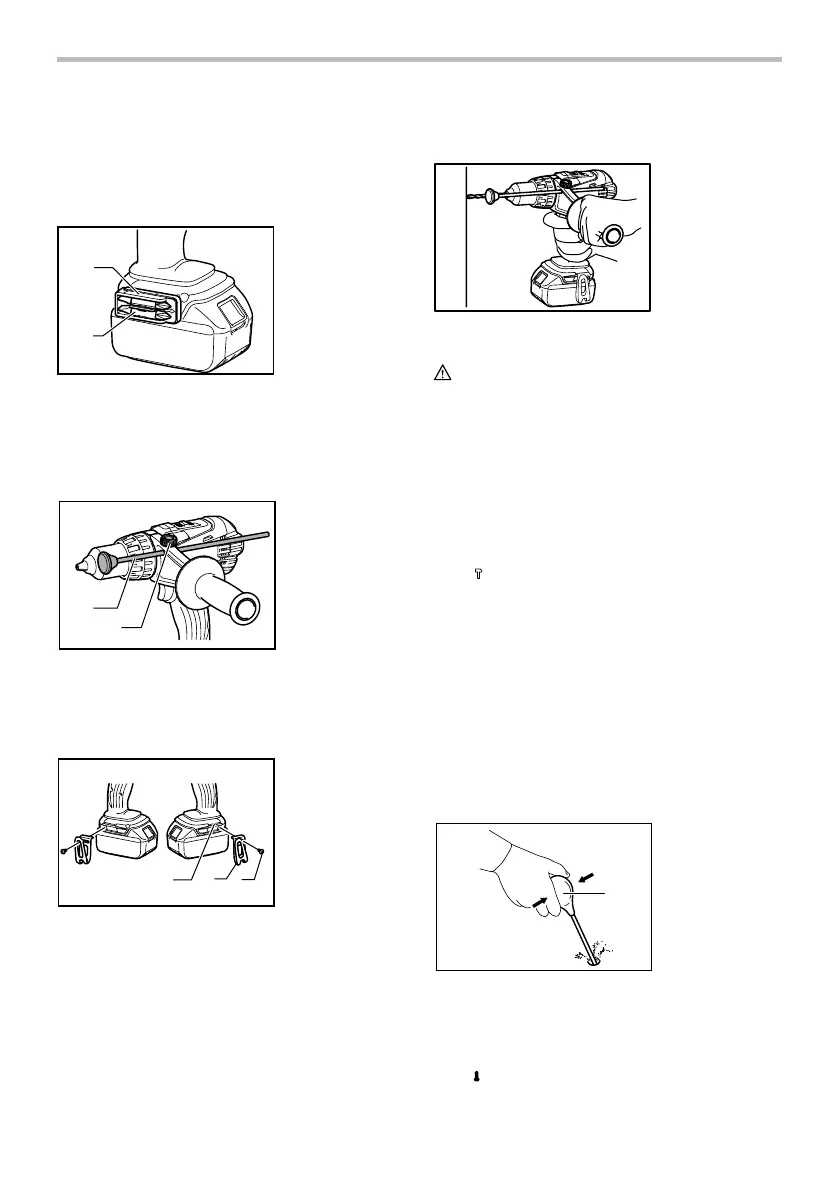

Blow-out bulb (optional accessory)

1

002449

After drilling the hole, use the blow-out bulb to clean the

dust out of the hole.

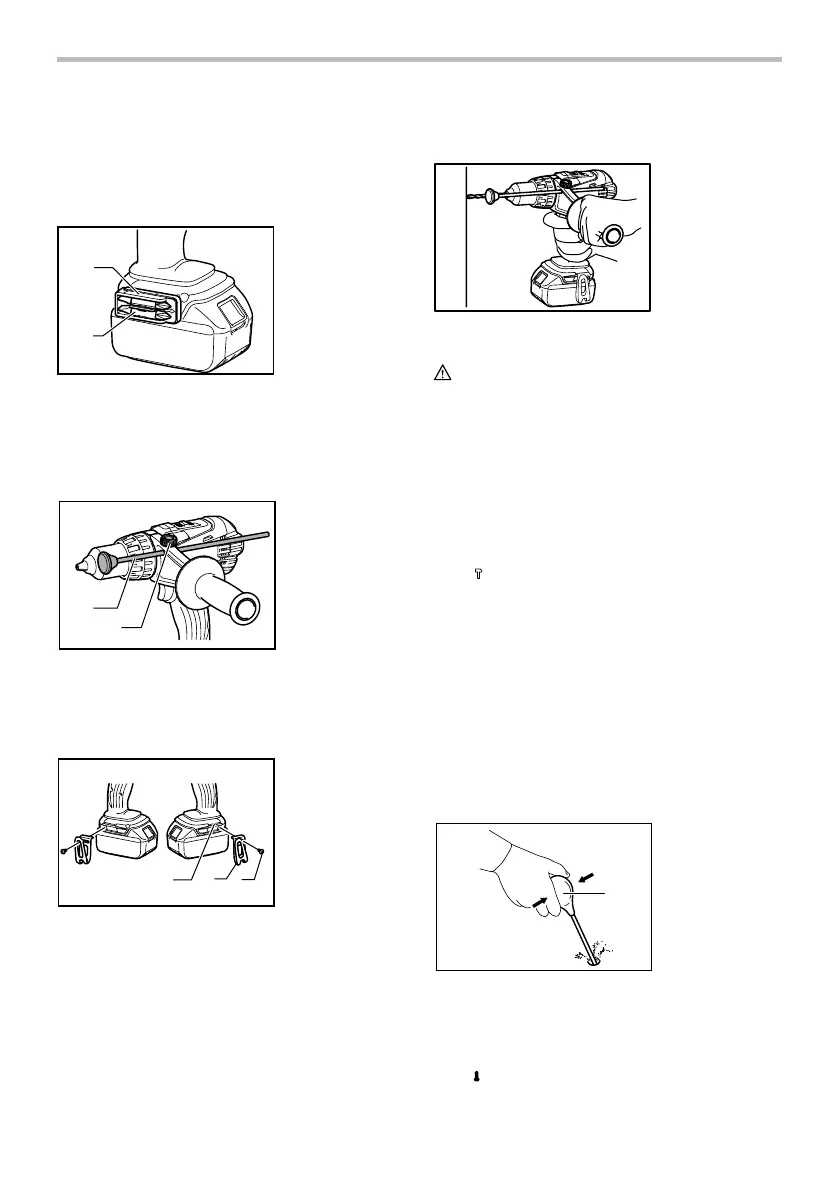

Screwdriving operation

First, slide the action mode change lever so that it points

to the

marking. Adjust the adjusting ring to the proper

torque level for your work. Then proceed as follows.

1. Blow-out bulb

1. Groove

2. Hook

3. Screw

1. Depth rod

2. Clamp screw

1. Bit holder

2. Bit

Loading...

Loading...