18

ENGLISH

30

30

55

55

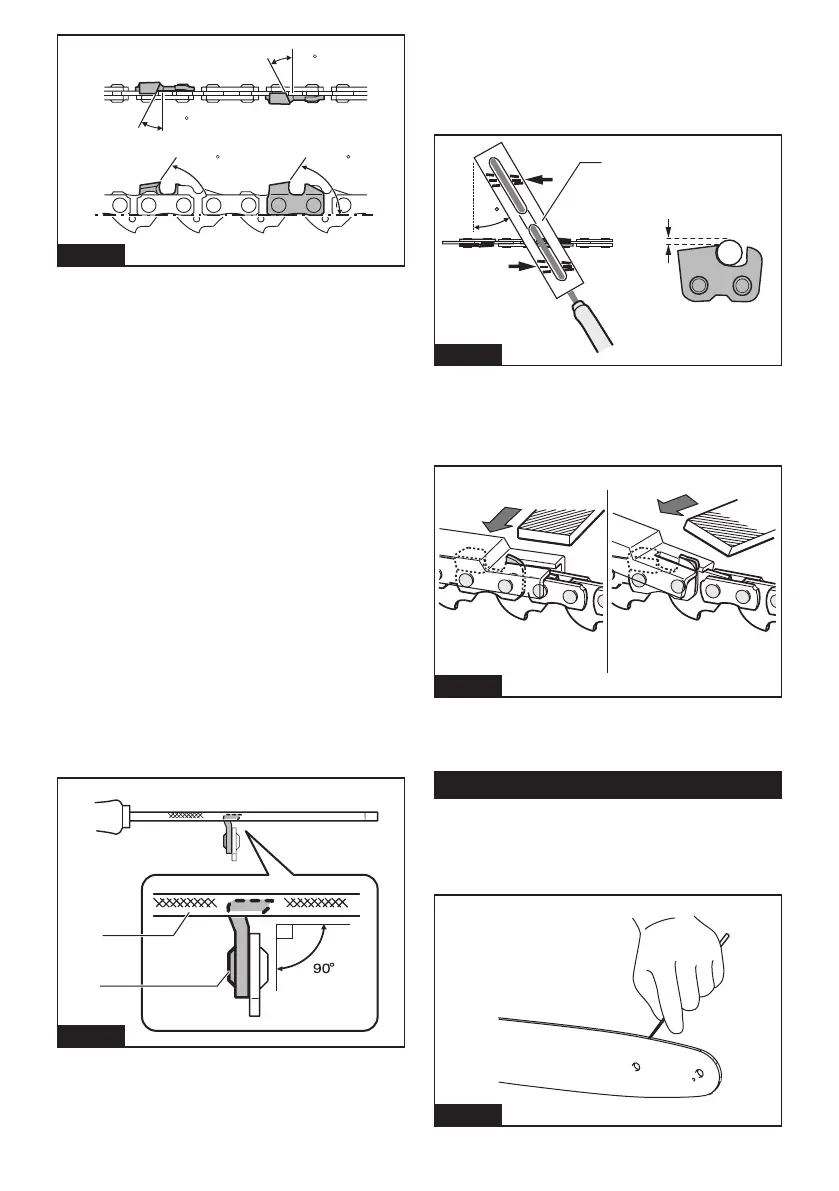

Fig.25

— The sharpening angle of 30° must be

the same on all cutters. Dierent cutter

angles cause the chain to run roughly and

unevenly, accelerate wear, and lead to

chain breaks.

— Use a suitable round le so that the proper

sharpening angle is kept against the teeth.

• Chain blade 90PX : 55°

Chain blade 80TXL : 55°

File and le guiding

— Use a special round le (optional accessory)

for saw chains to sharpen the chain. Normal

round les are not suitable.

— Diameter of the round le for each saw

chain is as follows:

• Chain blade 90PX : 4.5 mm (3/16″)

Chain blade 80TXL : 4.0 mm (5/32″)

— The le should only engage the cutter on

the forward stroke. Lift the le o the cutter

on the return stroke.

— Sharpen the shortest cutter rst. Then the

length of this shortest cutter becomes the

standard for all other cutters on the saw

chain.

— Guide the le as shown in the gure.

1

2

Fig.26

► 1. File 2. Saw chain

—

The le can be guided more easily if a le holder

(optional accessory) is employed. The le holder has

markings for the correct sharpening angle of 30° (align

the markings parallel to the saw chain) and limits the

depth of penetration (to 4/5 of the le diameter).

30

1/5

1

Fig.27

► 1. File holder

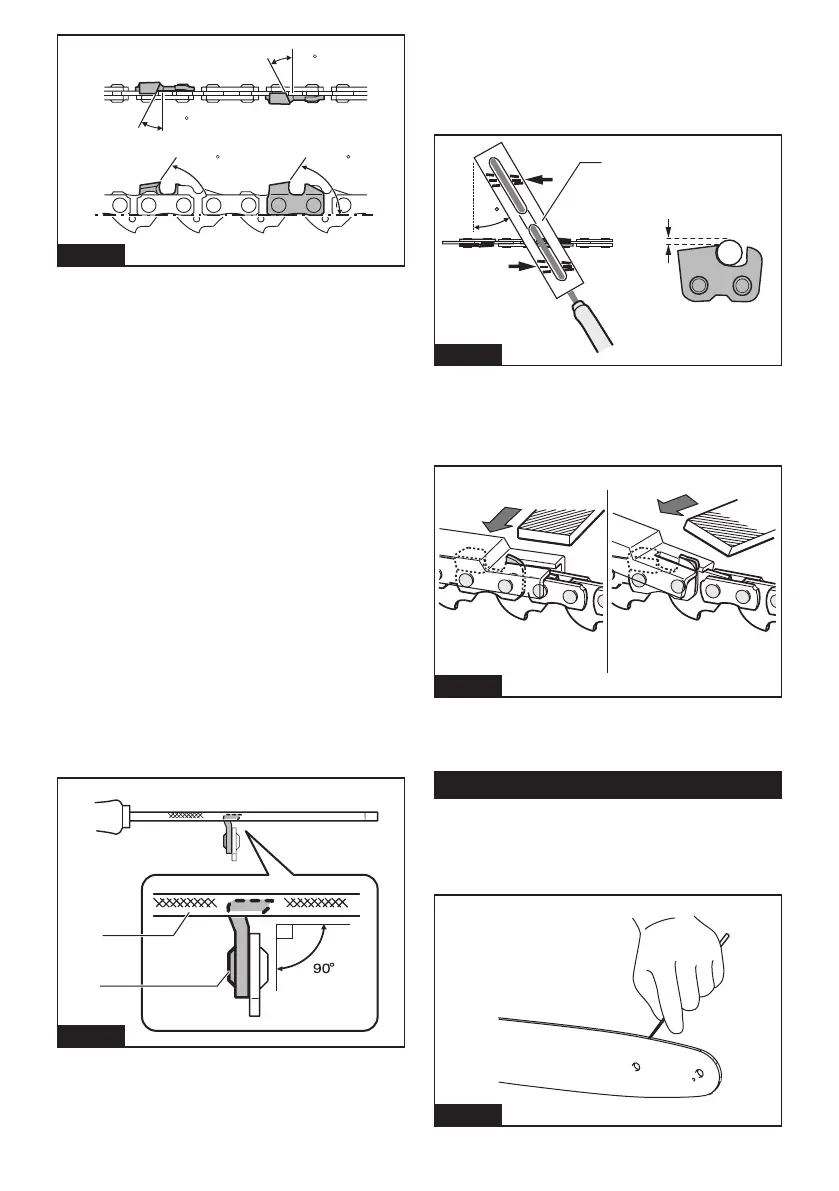

— After sharpening the chain, check the height

of the depth gauge using the chain gauge

tool (optional accessory).

Fig.28

—

Remove any projecting material, however small,

with a special at le (optional accessory).

—

Round o the front of the depth gauge again.

Cleaning the guide bar

Chips and sawdust will build up in the guide bar

groove. They may clog the bar groove and impair

the oil ow. Clean out the chips and sawdust every

time when you sharpen or replace the saw chain.

Fig.29

Loading...

Loading...