16 ENGLISH

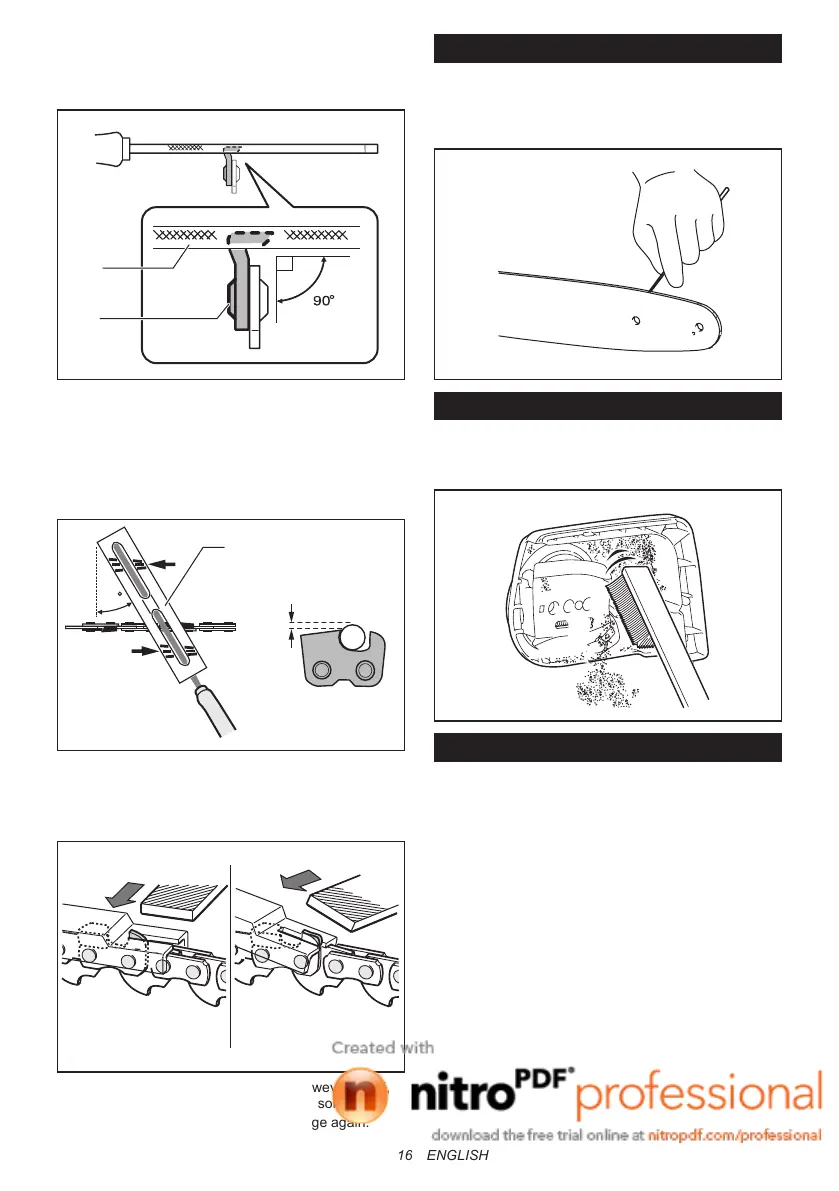

— Sharpentheshortestcutterrst.Thenthelength

of this shortest cutter becomes the standard for all

other cutters on the saw chain.

— Guidetheleasshowninthegure.

1

2

►1. File 2. Saw chain

— Thelecanbeguidedmoreeasilyifaleholder

(optionalaccessory)isemployed.Theleholder

has markings for the correct sharpening angle of

30° (align the markings parallel to the saw chain)

and limits the depth of penetration (to 4/5 of the

lediameter).

30

1/5

1

►1. File holder

— Aftersharpeningthechain,checktheheightofthe

depth gauge using the chain gauge tool (optional

accessory).

— Removeanyprojectingmaterial,howeversmall,

withaspecialatle(optionalaccessory).

— Round off the front of the depth gauge again.

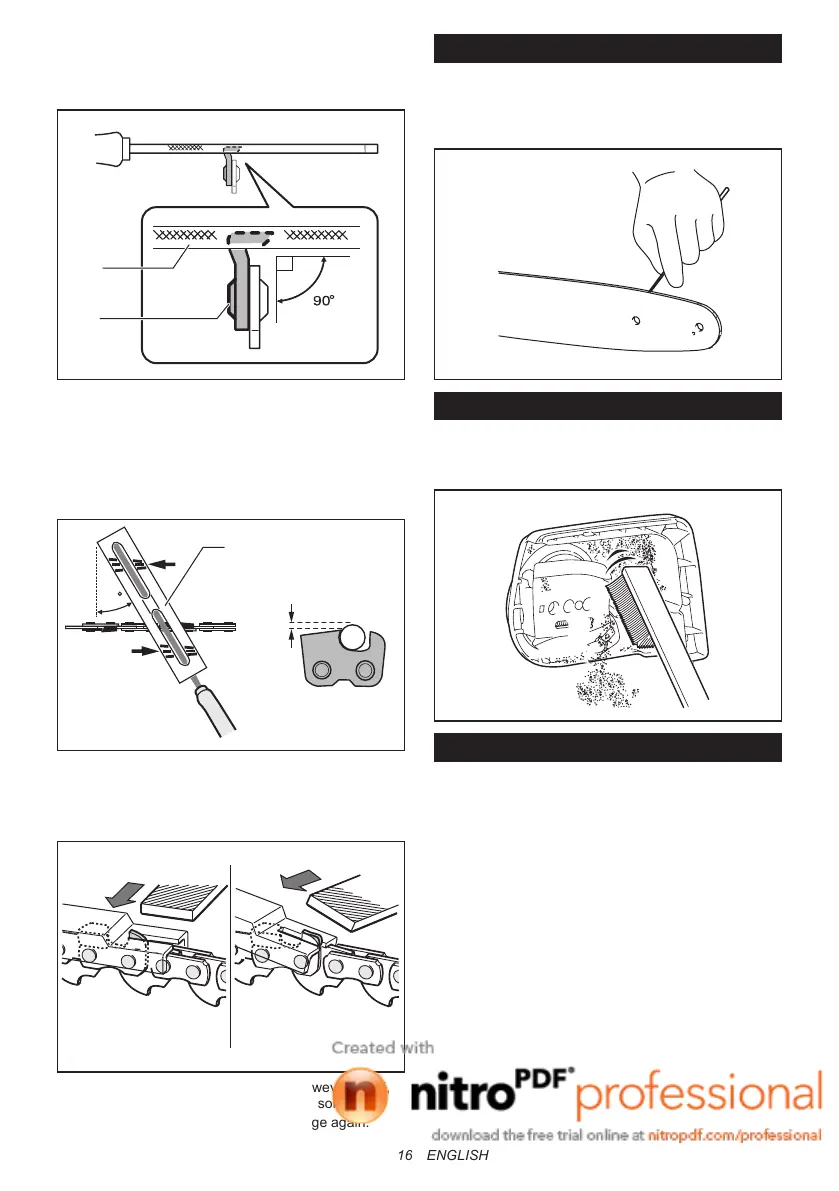

Cleaning the guide bar

Chips and sawdust will build up in the guide bar groove.

Theymayclogthebargrooveandimpairtheoilow.

Clean out the chips and sawdust every time when you

sharpen or replace the saw chain.

Cleaning the sprocket cover

Chips and saw dust will accumulate inside of the

sprocket cover. Remove the sprocket cover and saw

chain from the tool then clean the chips and saw dust.

Cleaning the oil discharge hole

Small dust or particles may be built up in the oil dis-

charge hole during operation. These dust or particles

mayimpairtheoiltoowandcauseaninsufcient

lubricationonthewholesawchain.Whenapoorchain

oil delivery occurs at the top of guide bar, clean the oil

discharge hole as follows.

1. Remove the sprocket cover and saw chain from

the tool.

2. Remove the small dust or particles using a slotted

screwdriver with a slender shaft or the like.

Loading...

Loading...