Loading...

Loading...

Do you have a question about the Makita LH1040F and is the answer not in the manual?

| Input power | 1650 W |

|---|---|

| Power source | AC |

| Blade diameter | 160 mm |

| Idle speed (max) | 4800 RPM |

| Sound pressure level | 92 dB |

| Cutting capacity 45° miter | 35 x 130 mm |

| Cutting capacity 45° incline | 69 x 130 mm |

| Depth | 530 mm |

|---|---|

| Width | 476 mm |

| Height | 535 mm |

| Weight | 14300 g |

Ensure a clean, well-lit workspace and keep bystanders clear to prevent accidents and injuries.

Follow electrical safety guidelines, including using proper outlets, avoiding wet conditions, and protecting cords.

Prioritize personal safety with alertness, proper PPE, and correct tool handling to prevent injuries.

Properly use and maintain the power tool, ensuring it's in good condition and used as intended to prevent damage.

Ensure the power tool is serviced by qualified personnel using identical replacement parts for safety and reliability.

Secure the auxiliary plate to the tool's base using the provided notch and hex bolt before operation.

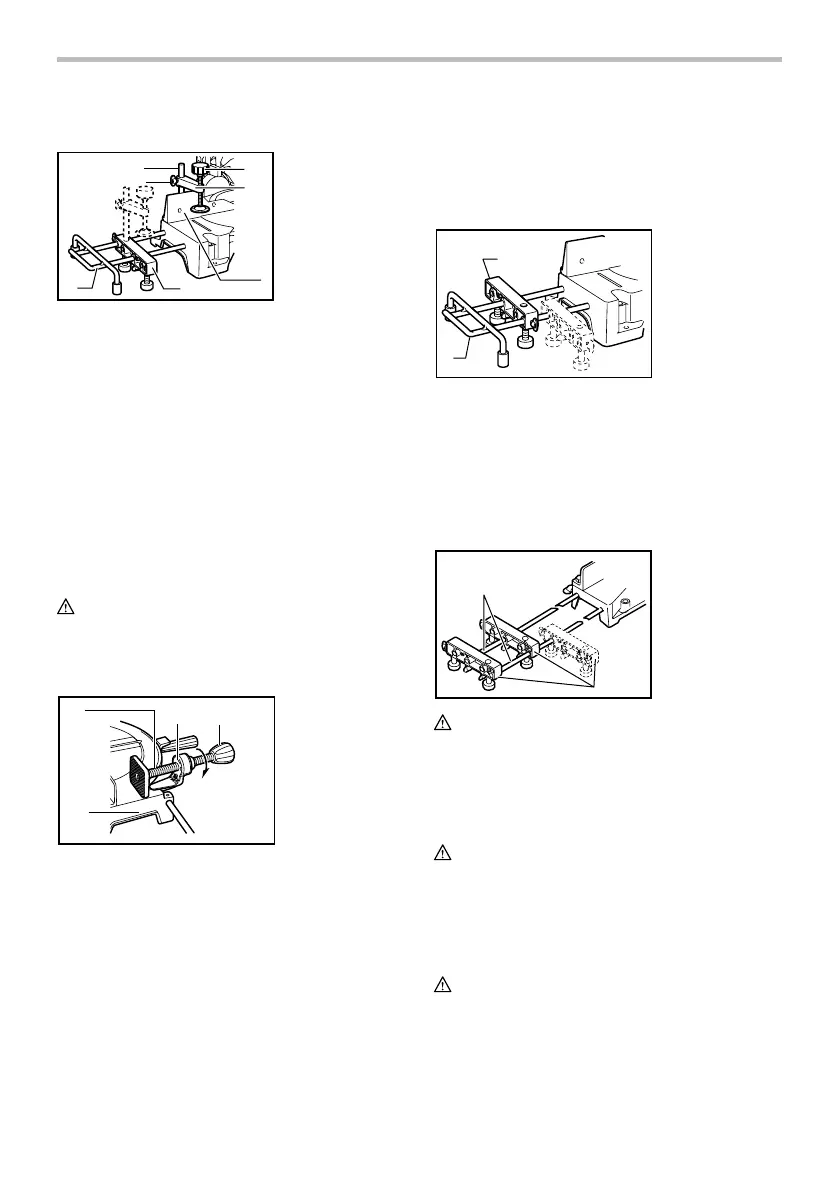

Attach and adjust holders on the base sides, ensuring they contact the floor surface for stability.

Bolt the tool securely to a stable surface via the base holes to prevent tipping and ensure safe operation.

Maintain blade guards in good condition and ensure their proper function; never remove or defeat them.

Ensure the tool is set up for maximum cutting capacity, checking blade position and adjusting if needed.

Set the desired bevel angle by loosening the lever, tilting the blade, and tightening the lever securely.

Verify the switch operates correctly before use; press ON to start and OFF to stop the tool.

Operate the lamp switch for visibility on the LH1040F model, avoiding direct light exposure.

Adjust the top table level by loosening levers, positioning the table, and re-tightening levers for correct mode operation.

Ensure the tool is unplugged before blade installation/removal, using the correct wrench and securing components properly.

Install and adjust the rip fence parallel to the blade to reduce kickback risk, aligning it with the workpiece edge.

Position the sub-fence correctly for cuts; flip outward for left bevel cuts to avoid blade contact.

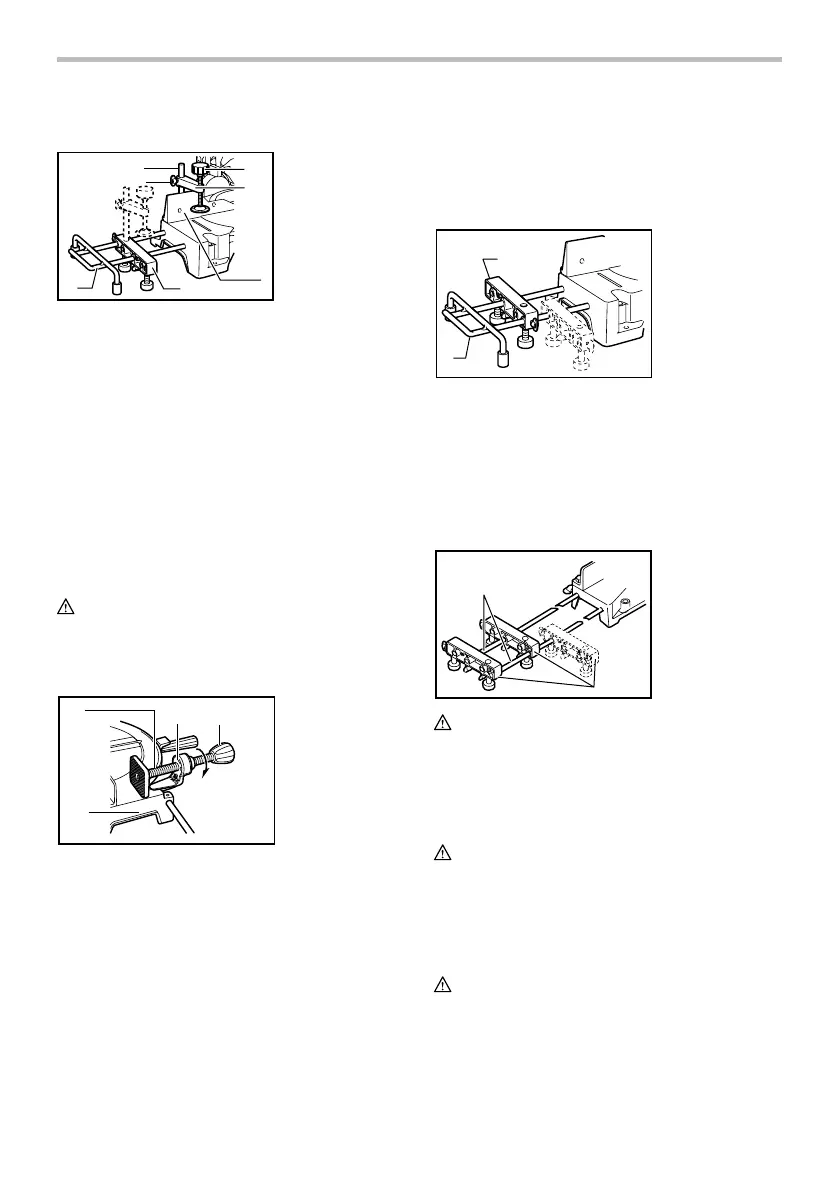

Install and use the vertical vise for secure workpiece holding, positioning it on the guide fence or holder assembly.

Install holders and holder assembly for horizontal workpiece support, especially for long pieces.

Install and use the horizontal vise for secure workpiece clamping, adjusting its position as needed.

When using miter saw mode, ensure the top table is at its highest position, preventing blade protrusion.

Secure workpiece, start tool, wait for full speed, gently lower handle, then stop and wait for blade to stop.

Perform miter cuts by following the 'Adjusting the Miter Angle' procedure for precise angle setting.

Execute bevel cuts by tilting the blade to the desired angle, ensuring safe operation and waiting for blade stop.

Combine miter and bevel angles for compound cuts, following specific procedures for accurate results.

Use the set plate for efficient cutting of multiple pieces to the same length, ensuring accurate positioning.

Operate in table saw mode with proper blade cover installation and safe practices like using push sticks.

Utilize work helpers like push sticks and blocks for safe cutting, preventing hand contact with the blade.

Construct and use a push block from plywood for safe feeding of workpieces, with protective features.

Install and use an auxiliary fence for narrow rips, providing a safe guide when push sticks are not feasible.

Check and adjust miter and bevel angles for proper alignment and accurate cutting results.

Fine-tune the miter angle alignment by adjusting the guide fence and blade position for square cuts.

Set and verify bevel angles accurately, ensuring the blade is correctly positioned at 0° or 45°.

Regularly inspect and replace carbon brushes when worn down to the limit mark for optimal tool performance.

Perform post-operation cleaning, lubrication, and seek professional service for maintenance to ensure safety.