23 ENGLISH

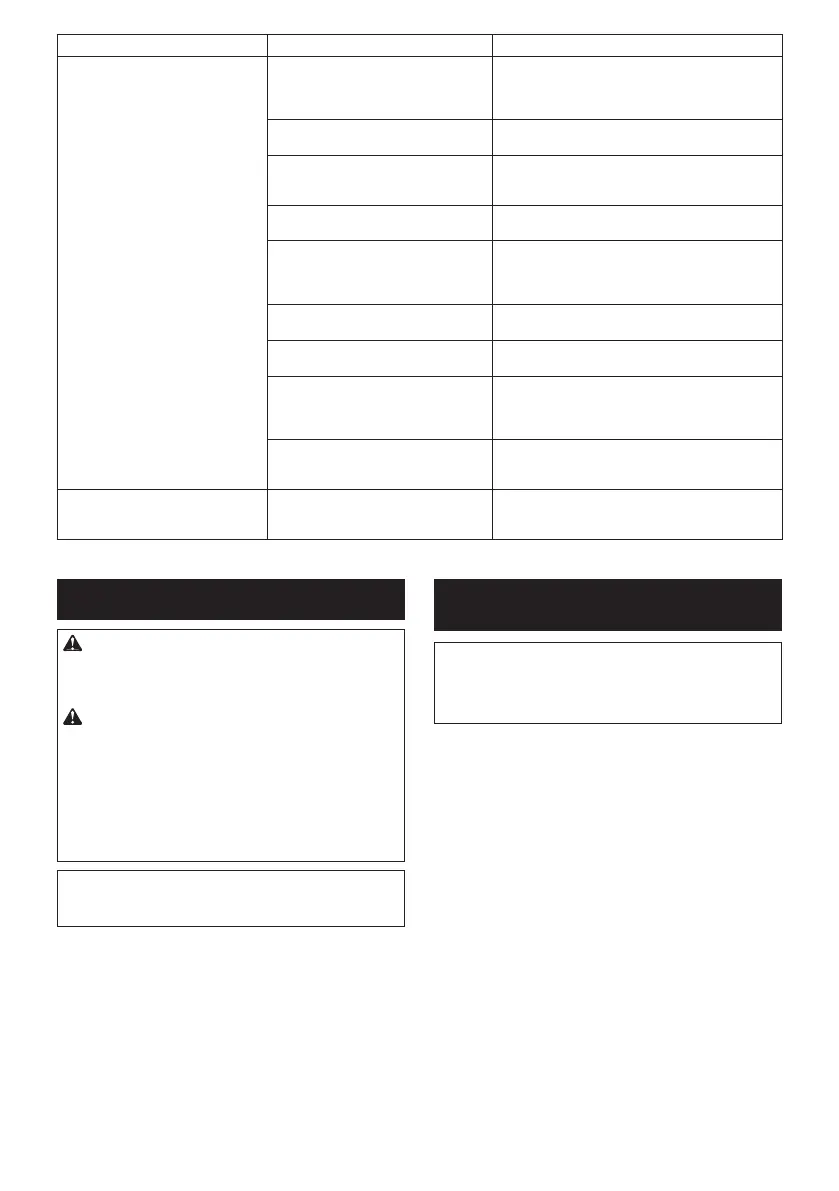

State of abnormality Probable cause (malfunction) Remedy

The vacuum cleaner does not run

along with the switch operation of

the tool.

The wireless unit is not installed into

the tool.

Thewirelessunitisimproperlyinstalled

into the tool.

Installthewirelessunitcorrectly.

The terminal of the wireless unit and/or

theslotisdirty.

Gentlywipeodustanddirtontheterminalofthe

wireless unit and clean the slot.

The wireless activation button on the

tool has not been pushed.

Pushthewirelessactivationbuttonbrieyandmake

sure that the wireless activation lamp is blinking

in blue.

Thestand-byswitchonthevacuum

cleaner is not set to “AUTO”.

Setthestand-byswitchonthevacuumcleanerto

“AUTO”.

More than 10 tools are registered to the

vacuum cleaner.

Perform the tool registration again.

If more than 10 tools are registered to the vacuum

cleaner, the tool registered earliest will be cancelled

automatically.

The vacuum cleaner erased all tool

registrations.

Perform the tool registration again.

Nopowersupply Supplythepowertothetoolandthevacuum

cleaner.

Thetoolandvacuumcleanerareaway

from each other (out of the transmission

range).

Get the tool and vacuum cleaner closer each other.

The maximum transmission distance is approxi-

mately10mhoweveritmayvaryaccordingtothe

circumstances.

Radiodisturbancebyotherappliances

whichgeneratehigh-intensityradio

waves.

Keepthetoolandvacuumcleanerawayfromthe

appliances such as Wi-Fi devices and microwave

ovens.

The vacuum cleaner runs while the

tool's switch trigger is not pulled.

Other users are using the wireless

activation of the vacuum cleaner with

their tools.

Turnothewirelessactivationbuttonoftheother

tools or cancel the tool registration of the other

tools.

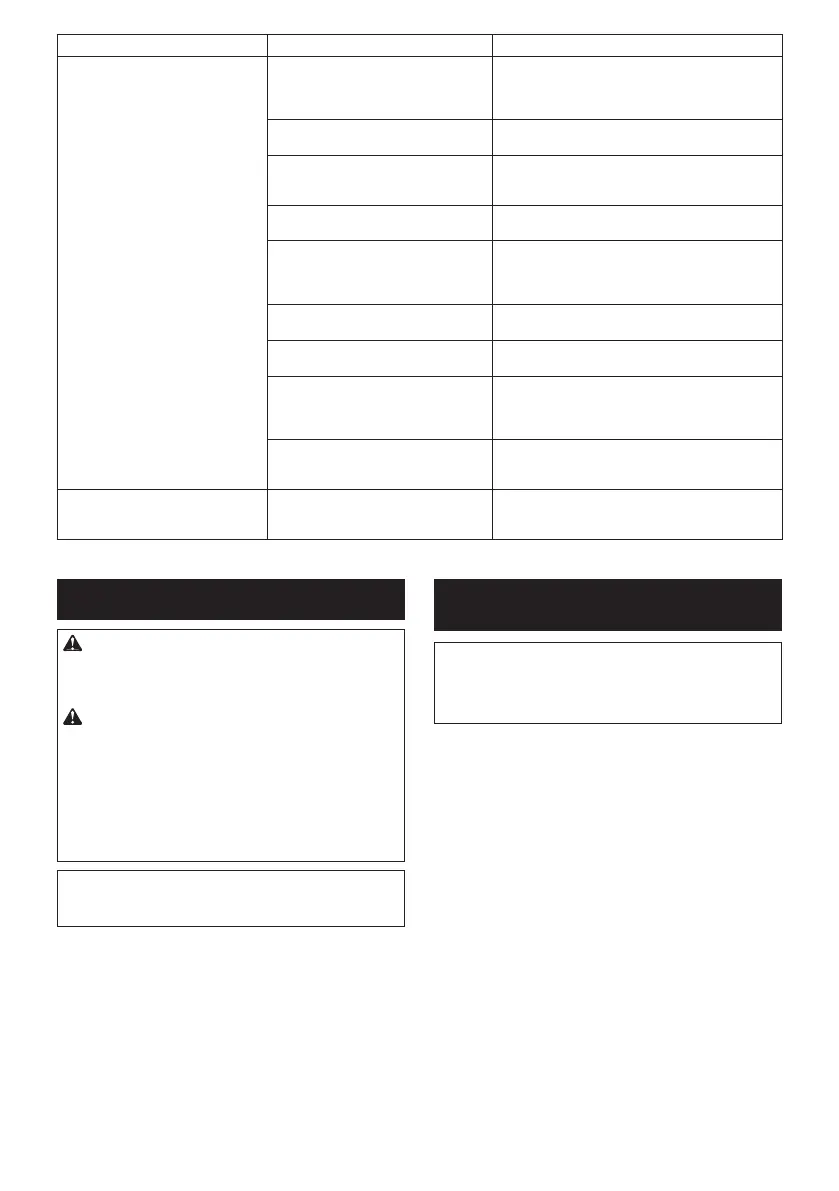

MAINTENANCE

CAUTION: Always be sure that the tool is

switched o and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

CAUTION: Clean out the guard to ensure

there is no accumulated sawdust which may

impede the operation of the guarding system. A

dirtyguardingsystemmaylimittheproperoperation

whichcouldresultinseriouspersonalinjury.The

mosteectivewaytoaccomplishthiscleaningiswith

compressed air. If the dust is being blown out of

the guard, be sure the proper eye and breathing

protection is used.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs,anyothermaintenanceoradjustmentshould

beperformedbyMakitaAuthorizedorFactoryService

Centers,alwaysusingMakitareplacementparts.

Adjusting 0°-cut and 45°-cut

accuracy

NOTICE: Do not engage the levers for -1° bevel

angle when adjusting 0°-cut accuracy.

NOTICE: Do not engage the lever for 48° bevel

angle when adjusting 45°-cut accuracy.

Theseadjustmentshavebeenmadeatthefactory.

Butiftheyareo,youcanadjustthemasthefollowing

procedures.

1. Slightlyloosentheclampingscrewsonthefront

and rear of the tool.

2. Adjustthebladeangle.

►Fig.44: 1. Triangular rule

Toadjustthe0°-cutaccuracy,makethebaseperpen-

dicular to the blade using a triangular rule, square rule,

etc.byturningtheadjustingbolt.

►Fig.45: 1.Adjustingboltfor0°-cut

Toadjustthe45°-cutaccuracy,makethebase45°to

thebladeusingatriangularrulebyturningtheadjusting

bolt.

►Fig.46: 1.Adjustingboltfor45°-cut

3. Tighten the clamping screws and make a test cut.

Loading...

Loading...