Coolant

inspecting

Summary

Acquire and check typical values of the operating media to prevent or limit

damage.

The fresh water used to fill the coolant circuits must satisfy the specifications.

The coolant in the system must be checked regularly in accordance with the

maintenance schedule.

The following work/steps is/are necessary:

Acquisition of typical values for the operating fluid,

evaluation of the operating fluid and checking the anticorrosive agent con-

centration.

Tools/equipment required

The following equipment can be used:

▪ The MAN Diesel & Turbo water testing kit, or similar testing kit, with all

necessary instruments and chemicals that determine the water hardness,

pH value and chloride content (obtainable from MAN Diesel & Turbo or

Mar-Tec Marine, Hamburg).

When using chemical additives:

▪ Testing equipment in accordance with the supplier's recommendations.

Testing kits from the supplier also include equipment that can be used to

determine the fresh water quality.

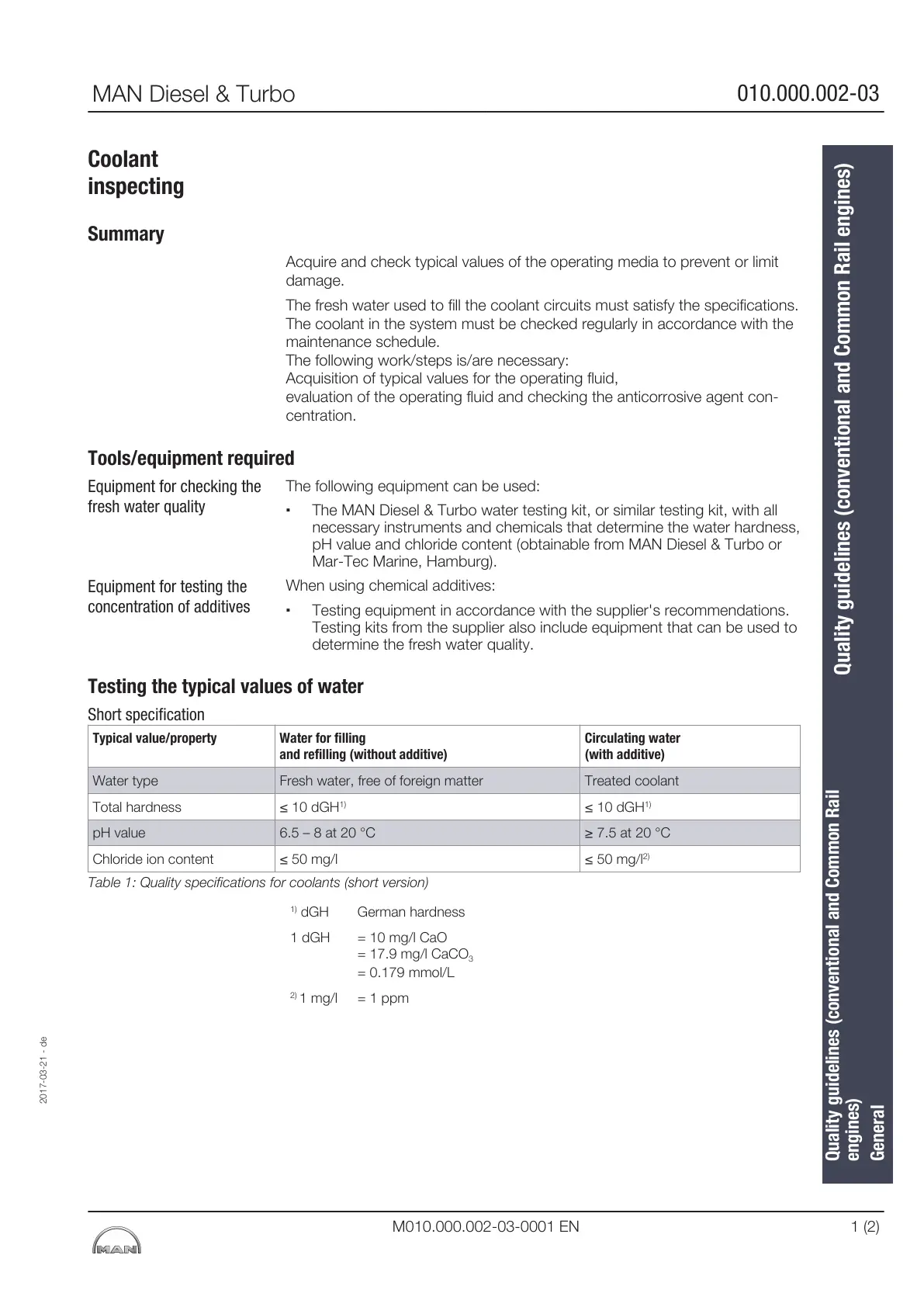

Testing the typical values of water

Typical value/property Water for filling

and refilling (without additive)

Circulating water

(with additive)

Water type Fresh water, free of foreign matter Treated coolant

Total hardness ≤ 10 dGH

1)

≤ 10 dGH

1)

pH value 6.5 – 8 at 20 °C ≥ 7.5 at 20 °C

Chloride ion content ≤ 50 mg/l ≤ 50 mg/l

2)

Table 1: Quality specifications for coolants (short version)

1)

dGH German hardness

1 dGH = 10 mg/l CaO

= 17.9 mg/l CaCO

3

= 0.179 mmol/L

2)

1 mg/l = 1 ppm

Equipment for checking the

fresh water quality

Equipment for testing the

concentration of additives

Short specification

2017-03-21 - de

Quality guidelines (conventional and Common Rail

engines)

Quality guidelines (conventional and Common Rail engines)

General

MAN Diesel & Turbo

010.000.002-03

M010.000.002-03-0001 EN 1 (2)

Loading...

Loading...