Coolant system

cleaning

Summary

Remove contamination/residue from operating fluid systems, ensure/re-

establish operating reliability.

Coolant systems containing deposits or contamination prevent effective cool-

ing of parts. Contamination and deposits must be regularly eliminated.

This comprises the following:

Cleaning the system and, if required,

removal of limescale deposits,

flushing the system.

Cleaning

The coolant system must be checked for contamination at regular intervals.

Cleaning is required if the degree of contamination is high. This work should

ideally be carried out by a specialist who can provide the right cleaning

agents for the type of deposits and materials in the cooling circuit. The clean-

ing should only be carried out by the engine operator if this cannot be done

by a specialist.

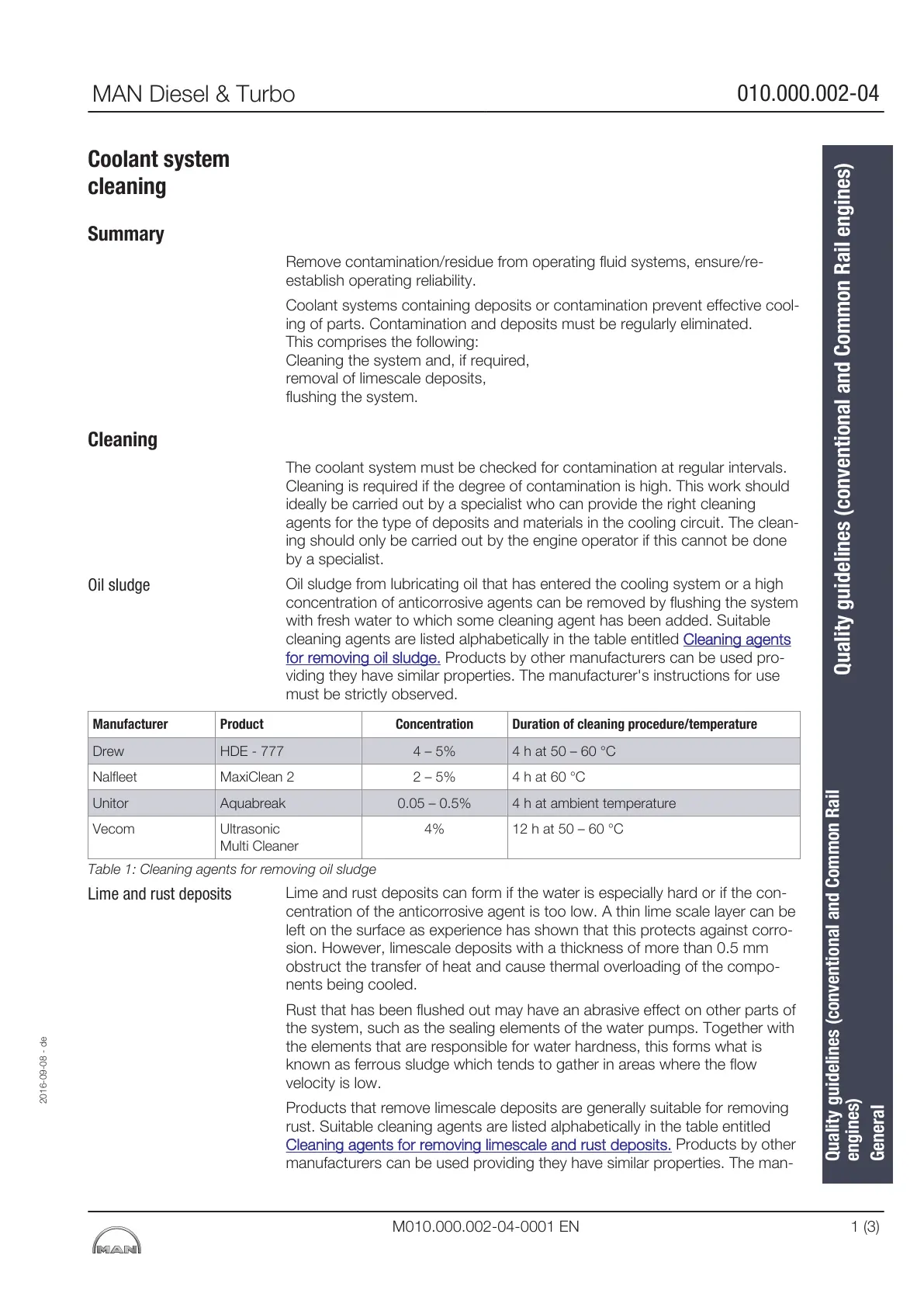

Oil sludge from lubricating oil that has entered the cooling system or a high

concentration of anticorrosive agents can be removed by flushing the system

with fresh water to which some cleaning agent has been added. Suitable

cleaning agents are listed alphabetically in the table entitled Cleaning agents

for removing oil sludge. Products by other manufacturers can be used pro-

viding they have similar properties. The manufacturer's instructions for use

must be strictly observed.

Manufacturer Product Concentration Duration of cleaning procedure/temperature

Drew HDE - 777 4 – 5% 4 h at 50 – 60 °C

Nalfleet MaxiClean 2 2 – 5% 4 h at 60 °C

Unitor Aquabreak 0.05 – 0.5% 4 h at ambient temperature

Vecom Ultrasonic

Multi Cleaner

4% 12 h at 50 – 60 °C

Table 1: Cleaning agents for removing oil sludge

Lime and rust deposits can form if the water is especially hard or if the con-

centration of the anticorrosive agent is too low. A thin lime scale layer can be

left on the surface as experience has shown that this protects against corro-

sion. However, limescale deposits with a thickness of more than 0.5 mm

obstruct the transfer of heat and cause thermal overloading of the compo-

nents being cooled.

Rust that has been flushed out may have an abrasive effect on other parts of

the system, such as the sealing elements of the water pumps. Together with

the elements that are responsible for water hardness, this forms what is

known as ferrous sludge which tends to gather in areas where the flow

velocity is low.

Products that remove limescale deposits are generally suitable for removing

rust. Suitable cleaning agents are listed alphabetically in the table entitled

Cleaning agents for removing limescale and rust deposits. Products by other

manufacturers can be used providing they have similar properties. The man-

Oil sludge

Lime and rust deposits

2016-09-08 - de

Quality guidelines (conventional and Common Rail

engines)

Quality guidelines (conventional and Common Rail engines)

General

MAN Diesel & Turbo

010.000.002-04

M010.000.002-04-0001 EN 1 (3)

Loading...

Loading...