G - OCCASIONAL MAINTENANCE

G1 - FUEL SYSTEM

BLEED

These operations are to be carried out only in the following cases:

• A component of the fuel system replaced.

• A drained tank.

• Running out of fuel.

Ensure that the level of fuel in the tank is sufficient and bleed in the following order:

- Open the I.C. engine bonnet.

- Put the ignition on for three minutes on the lift truck, to give the lift pump time to release

air from the filter.

- Switch off the ignition with the ignition key.

BLEEDING THE INJECTORS

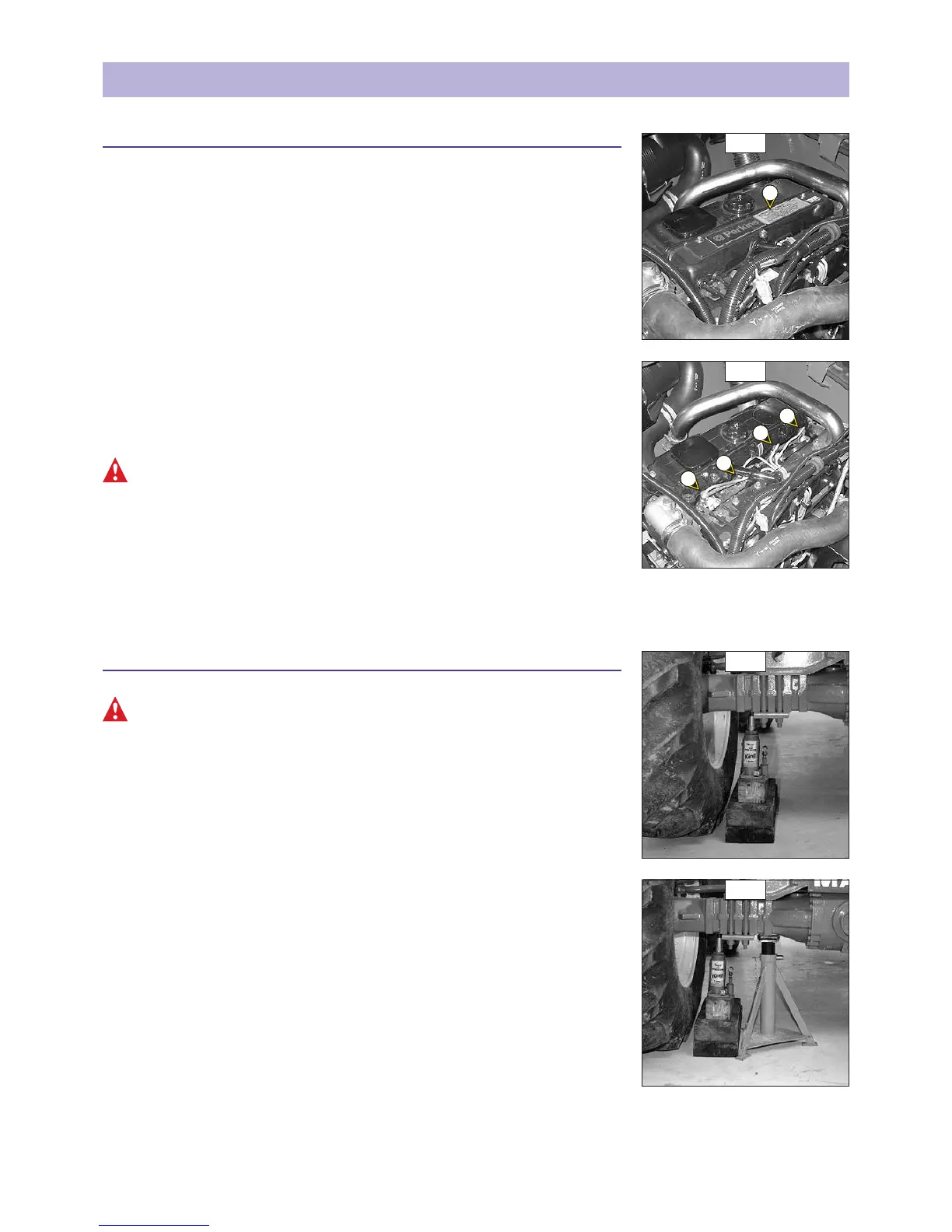

- Remove the injectors cover 1 (fig. G1/1).

- Loosen high pressure connectors 2 (fig. G1/2) of all the injectors.

- Activate the starter until the diesel fuel flows out free of air at high pressure connectors

2 (fig. G1/2).

Do not engage the starter motor on a continual basis for more than 30 seconds and let it cool

between unsuccessful attempts.

- Tighten the connection while the diesel fuel is flowing out (tightening torque 22 ft/lb).

- The I.C. engine is then ready to be started up.

- Turn the I.C. engine over slowly for 5 minutes immediately after bleeding the fuel feed

circuit, in order to ensure that the injection pump has been bled thoroughly.

NOTE: If the I.C. engine functions correctly for a short time then stops or functions irregularly, check for possible leaks in the low

pressure circuit. If in doubt, contact your dealer.

G2 - WHEEL

CHANGE

In the event of a wheel being changed on the public highway, make sure of the following points:

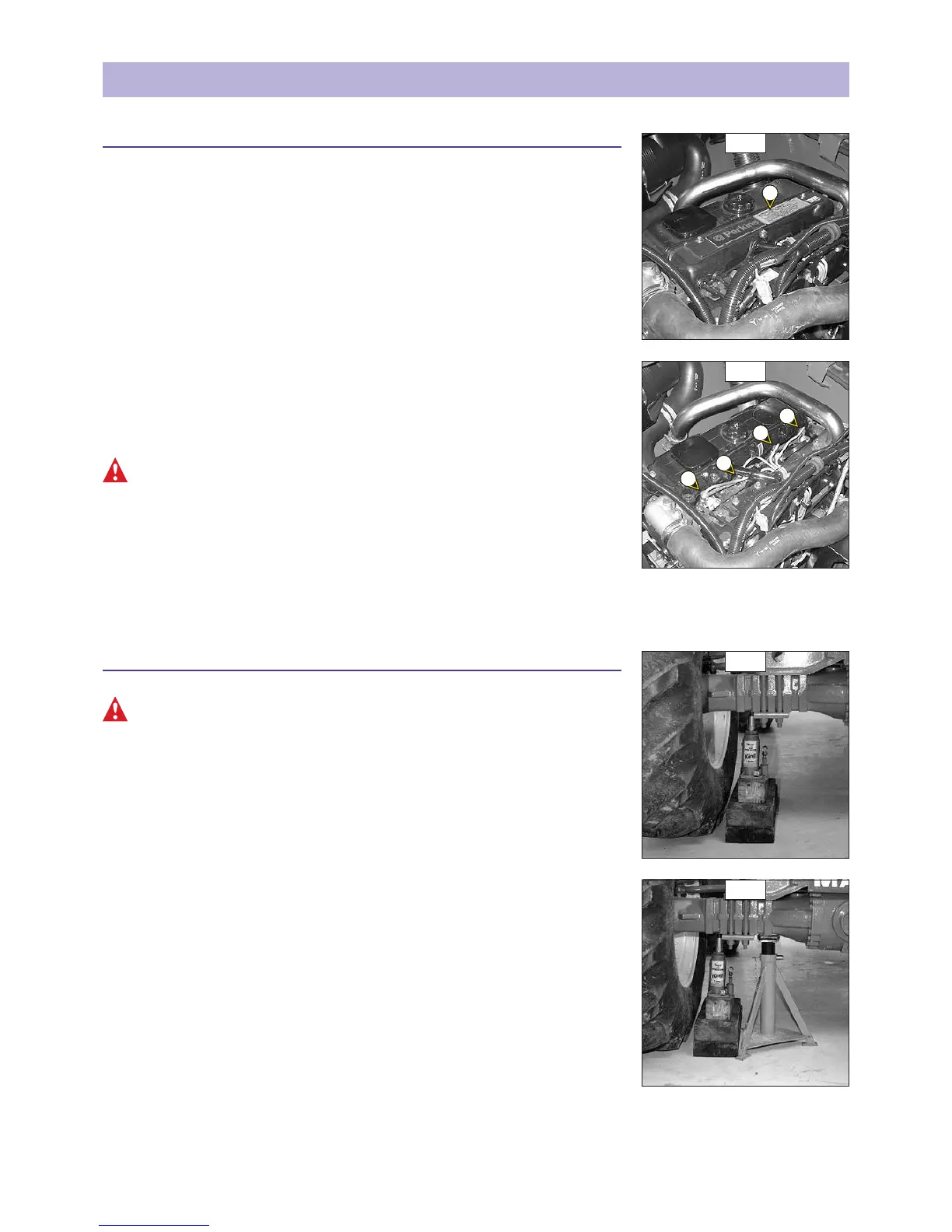

For this operation, we advise you to use an approved hydraulic jack and safety support.

- Stop the lift truck, if possible on even and hard ground.

- To pass on stop of lift truck (see: 1 - OPERATING AND SAFETY INSTRUCTIONS: DRIVING

INSTRUCTIONS UNLADEN AND LADEN).

- Put the warning lights on.

- Immobilise the lift truck in both directions on the axle opposite to the wheel to be

changed.

- Unlock the nuts of the wheel to be changed.

- Place the jack under the flared axle tube, as near as possible to the wheel and adjust the

jack (fig. G2/1).

- Lift the wheel until it comes off the ground and put in place the safety support under the

axle (fig. G2/2).

- Completely unscrew the wheel nuts and remove them.

- Free the wheel by reciprocating movements and roll it to the side.

- Slip the new wheel on the wheel hub.

- Refit the nuts by hand, if necessary grease them.

- Remove the safety support and lower the lift truck with the jack.

- Tighten the wheel nuts with a torque wrench (see: 3 - MAINTENANCE: A - DAILY OR EVERY

10 HOURS SERVICE for tightening torque).

G2/1

G2/2

G1/1

G1/2

2

2

2

2

1

3 - 38

Loading...

Loading...