Do you have a question about the Manitowoc QD1302A and is the answer not in the manual?

| Ice Type | Half Dice |

|---|---|

| Weight | 285 lbs |

| Condenser | Air-Cooled |

| Production Capacity | 1300 lb/24 hours |

| Power Supply | 208-230/60/1 |

| Refrigerant | R404A |

| Ice Production | 130 lbs per day |

Warning about operating misused, abused, neglected, or altered equipment.

Alerts to potential personal injury situations.

Provides useful information for performing procedures efficiently.

Explains the structure of model numbers.

Details the warranty terms and conditions.

Provides physical dimensions of ice machines.

Provides dimensions for ice storage bins.

Provides dimensions for remote condensers.

Critical for proper operation and maintenance.

Ensures proper functionality and door seal.

Critical for safe and proper operation.

Essential for proper electrical hookup.

Essential for proper electrical hookup of remote units.

Crucial for ice machine function and longevity.

Key installation steps for remote setups.

Procedure for determining optimal placement.

Instructions for operating the service valve.

Guidelines for using third-party condensers.

Comprehensive checklist for installation verification.

Identifies key parts of the ice machine.

Routine checks for proper operation.

Essential for maintaining performance.

Crucial for hygiene and performance.

Step-by-step cleaning instructions.

Step-by-step sanitizing instructions.

Details on the automated cleaning accessory.

Maintenance and cleaning of the probe.

Maintenance and cleaning of the water inlet valve.

Steps for replacing filter cartridges.

Procedures for preparing the machine for storage.

Describes the operational sequence for these models.

Details the harvest cycle.

Describes the operational sequence for remote models.

Covers initial power-up procedures.

Lists parts energized during different operational states.

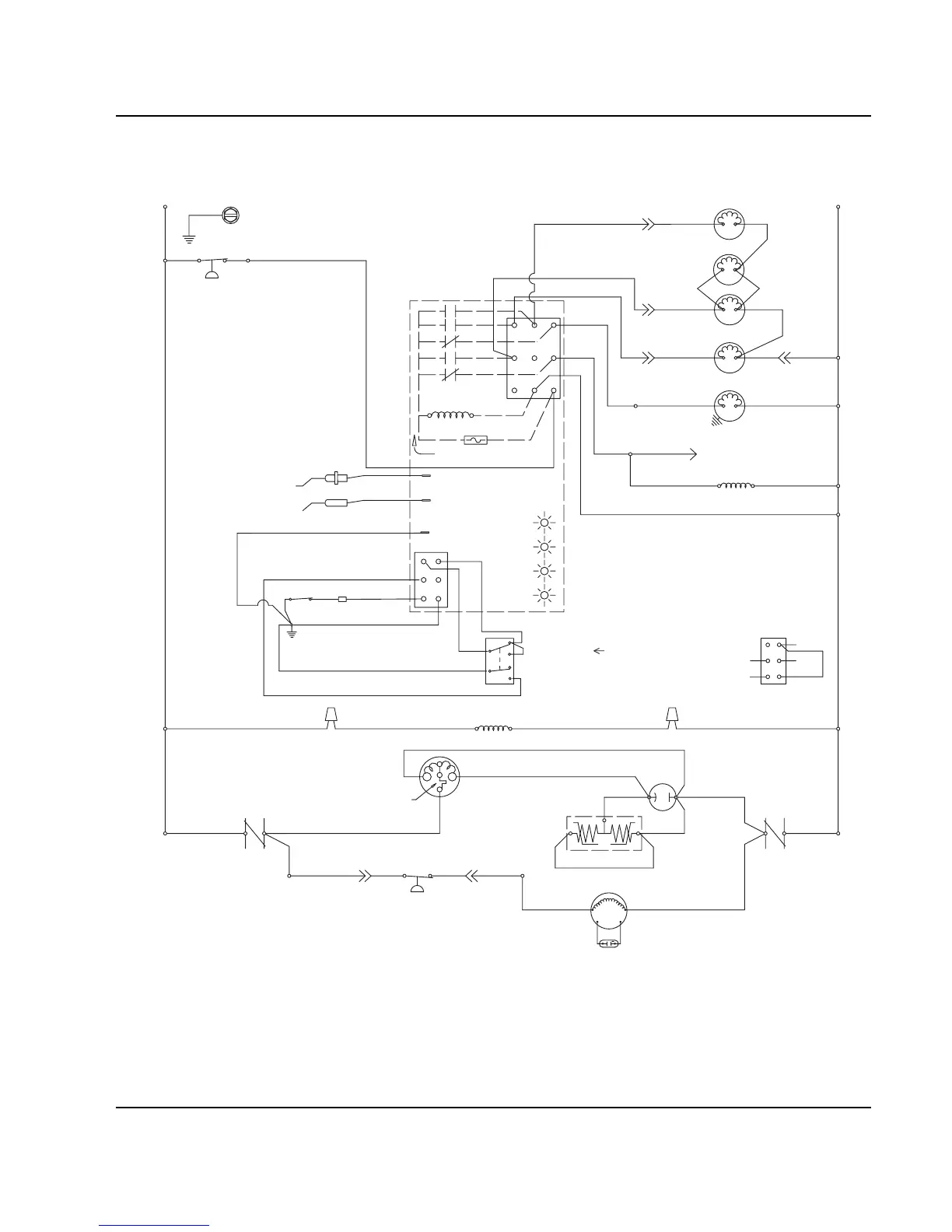

Explains the wiring diagrams.

Details the initial electrical startup sequence.

Electrical aspects of the freeze sequence.

Electrical aspects of the harvest sequence.

Electrical sequence for automatic shut-off.

Electrical specifics for remote models.

Electrical sequence during freeze for remote models.

Electrical sequence during harvest for remote models.

Electrical sequence for automatic shut-off for remote models.

Provides various wiring diagrams.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Wiring diagram for specific models.

Component specs and diagnostic procedures.

Troubleshooting compressor electrical issues.

Explains PTCR function and diagnostics.

Common PTCR failure modes and troubleshooting.

Step-by-step guide to checking the PTCR.

Function and testing of the toggle switch.

Overview of the control board components.

Built-in safety features of the control board.

How the probe works and initiates harvest.

Troubleshooting the ice thickness circuit.

Troubleshooting premature harvest.

How the water level is controlled.

Troubleshooting water level control issues.

Troubleshooting no water flow.

Troubleshooting general startup issues.

Explains how the refrigeration system works.

Details the harvest cycle refrigeration.

Refrigeration sequence for remote models.

Automatic shut-off in the refrigeration system.

Diagrams of the refrigeration tubing.

Key section for troubleshooting.

How to check ice production.

Checklist for installation verification.

Analyzing ice formation for diagnostics.

Explains safety limits and their indications.

Details on safety limit 1.

Critical diagnostic procedure.

Critical diagnostic procedure.

Diagnostic procedure.

Diagnostic procedure.

Guide to using diagnostic tables.

The actual analysis tables.

Explanation of the HPR system.

Troubleshooting the HPR system.

Operation and diagnostics of the headmaster valve.

Procedure to check for low refrigerant charge.

Specs and diagnostics for pressure controls.

Data charts for various models.

Essential procedure for handling refrigerant.

Steps for charging refrigerant.

Specifics for remote units.

Steps for charging refrigerant in remote units.

Procedures for cleaning contaminated systems.

Steps for mild contamination.

Procedure to replace controls without discharging refrigerant.

Information about filter-driers.

Definitions related to refrigerant handling.

Guidelines for refrigerant reuse.

Important information about HFC refrigerants.