4

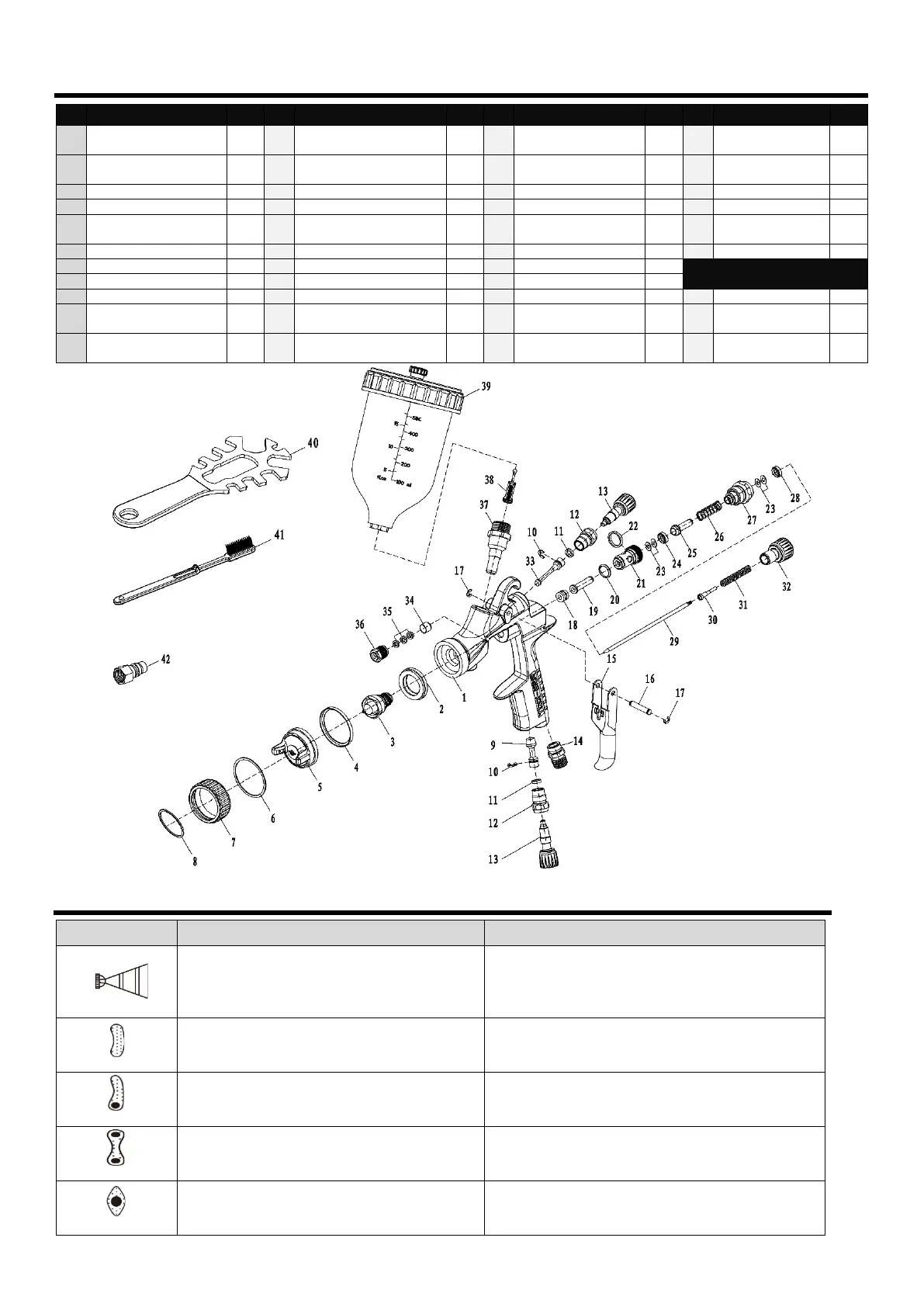

Parts list

1 Gun body 1 12

Air/pattern adjusting

valve housing

2 23 Air valve shaft seal 2 34 Needle packing 1

2 Air baffle 1 13

Air/pattern adjusting

knob

2 24

Air valve shaft seal

guide

1 35

1

5 Air cap 1 16 Trigger pivot 1 27

Needle/fluid

adjusting guide

1 38 Filter 1

Accessories

10 Circlip 5 2 21 Air valve housing 1 32

Needle/fluid

adjusting knob

1 41 Brush A 1

11

Air/pattern adjusting

valve seal

2 22 Air valve seal 1 33

Pattern adjusting

valve rod

1 42 Plug 1

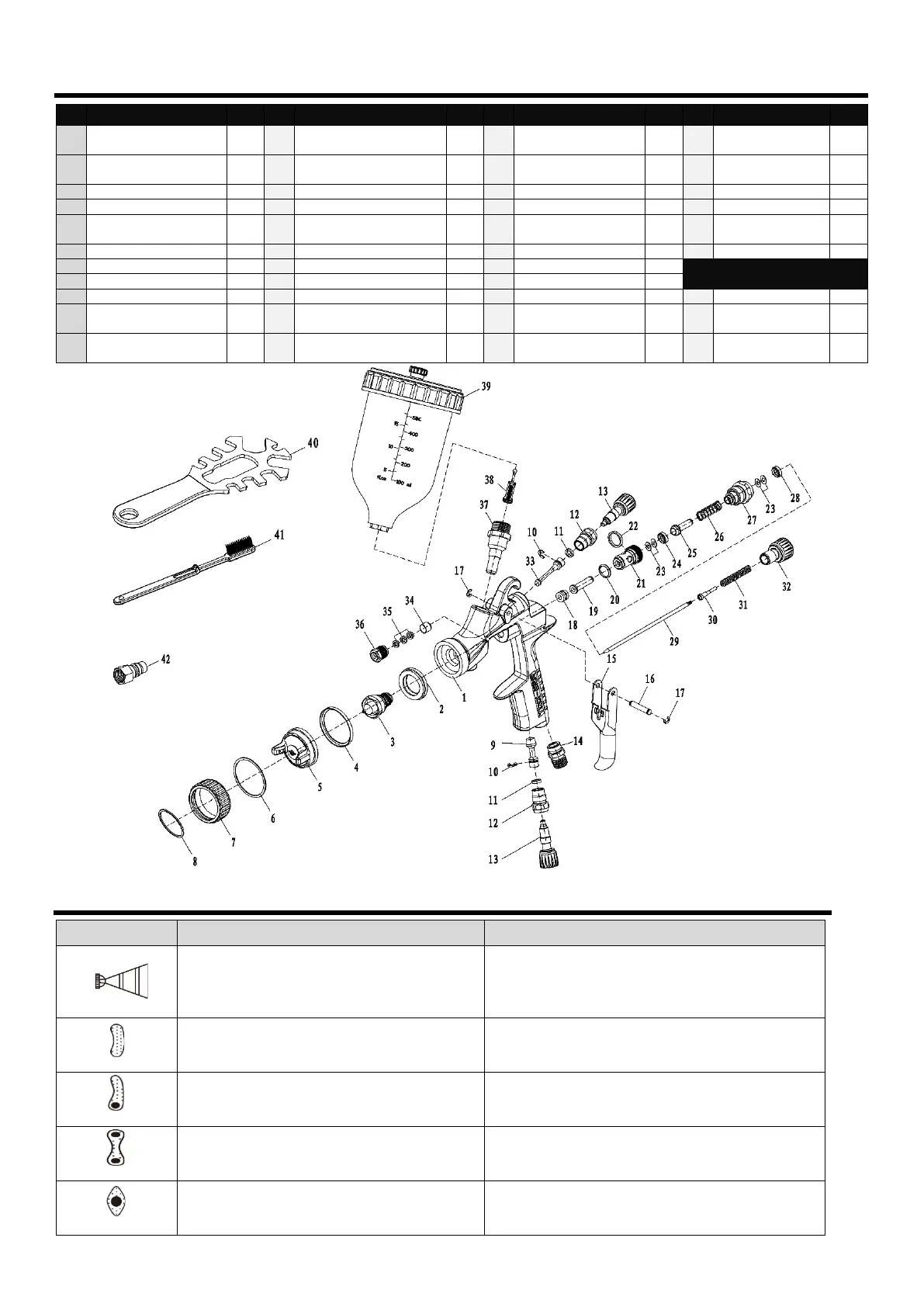

Troubleshooting

1. Air enters among fluid nozzle, air baffle and gun

body. It may caused by over-tightened nozzle

(>20Nm).

2. Air is drawn from fluid needle packing set.

3. Air enters at fluid inlet or fluid hose joint.

1. Remove fluid nozzle to clean. If it is damaged, replace

nozzle.. Do not over-tighten the nozzle.

2. Tighten fluid needle packing screw.

3. Tighten fluid inlet after clean.

Paint buildup on air cap partially clogs horn holes.

Air pressure from both horns is different.

Remove obstructions from horn holes with attached brush.

But do not use metal objects to clean horn holes.

1. Paint buildup or damage on fluid nozzle

circumference and air cap center.

2. Fluid nozzle is not properly fitted.

1. Clean the paint buildup. If it is damaged, replace the

damaged part.

2. Remove the nozzle and clean it.

1. Paint viscosity too low.

2. Fluid output too high.

1. Add paint to increase viscosity.

2. Tighten needle adjust knob to reduce fluid output. Or

turn pattern adjust valve set clockwise.

1. Paint viscosity is too high.

2. Fluid output too low.

1. Add thinner to reduce viscosity.

2. Turn needle adjust knob counter-clockwise to increase

fluid output.

www.tcpglobal.com

Loading...

Loading...