SERVICE

Tool service must be performed only by qualified

personnel. Service or maintenance performed by

unqualified personnel could result in risk of injury.

When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section

of this manual. Use of unauthorized parts or failure to

follow Maintenance instructions may create a risk of

electric shock or injury.

SPECIFIC SAFETY RULES

Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a

“live” wire will make exposed metal parts of the tool “live”

and shock the operator.

Always make sure the work surface is free from nails

and other foreign objects. Cutting into a nail can cause

the bit and the tool to jump and damage the bit.

Never hold the workpiece in one hand and the tool in

the other hand when in use. Never place the hands

near or below the cutting surface. Clamping the

material and guiding the tool with both hands is much

safer.

Never lay workpiece on hard surfaces like concrete,

stone, etc. Protruding cutting bit may cause tool to jump.

Always wear safety goggles and dust mask. Use only

in well ventilated area. Using personal safety devices

and working in a safe environment reduces risk of injury.

After changing the bits or making adjustments, make

sure the collet nut and any other adjustment devices

are securely tightened. Loose adjustment devices will be

violently thrown.

Never use dull or damaged bits. Sharp bits must be

handled with care. Damaged bits can snap during use.

Dull bits require more force to push the tool, possibly

causing the bit to break.

Never touch the bit during or immediately after use.

After use the bit is too hot to be touched by bare hands.

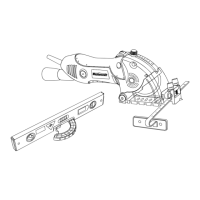

ANGLE GRINDER ATTACHMENT SAFETY

Always wear safety goggles with side shields or a face

mask when using the angle grinder attachment. High

speed grinding and sanding will throw hot sparks and

dust particles that could cause serious injury to your

eyes.

Always wear hearing protection when using the angle

grinder attachment.

Always use appropriate dust mask when using the

angle grinder attachment.

Use ONLY grinding wheels and sanding discs rated

for speeds greater than 18,000 RPM, as the angle

grinder attachment runs at speeds from 12,000 –

18,000 RPM.

Inspect the grinding wheel before each use to make

sure it is tightly fastened and free from cracks or any other

damages.

Rotate the guard to a position where it will protect the

operator from sparks & dust. The guard should be

positioned immediately in front of the side handle to

protect the operator’s hand.

Do not over tighten the nut holding the grinding wheel

in place. Excessive tightening may cause the grinding

wheel to crack and possibly shatter during operation.

Do not clamp the angle grinder attachment in a vice or

use as a fixed grinder.

Hold the angle grinder attachment securely with two

hands at all times while it is running.

Never turn the motor switch ON with the grinding

wheel or sanding disc touching the work surface.

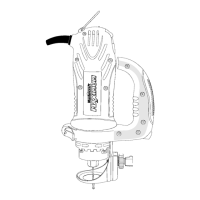

FLEXIBLE SHAFT SAFETY

When using the flexible shaft, always hang the Spin

Saw on its stand, using the hanging loop at the top of the

motor housing.

Always use safety glasses, hearing protection and a

dust mask.

Never hold the workpiece with your hand while using

a cutting bit. Clamp the workpiece in a vice or to a

workbench to permit using two hands on the flexible shaft.

Never place hands in the path of the cutter or under the

workpiece.

Loading...

Loading...