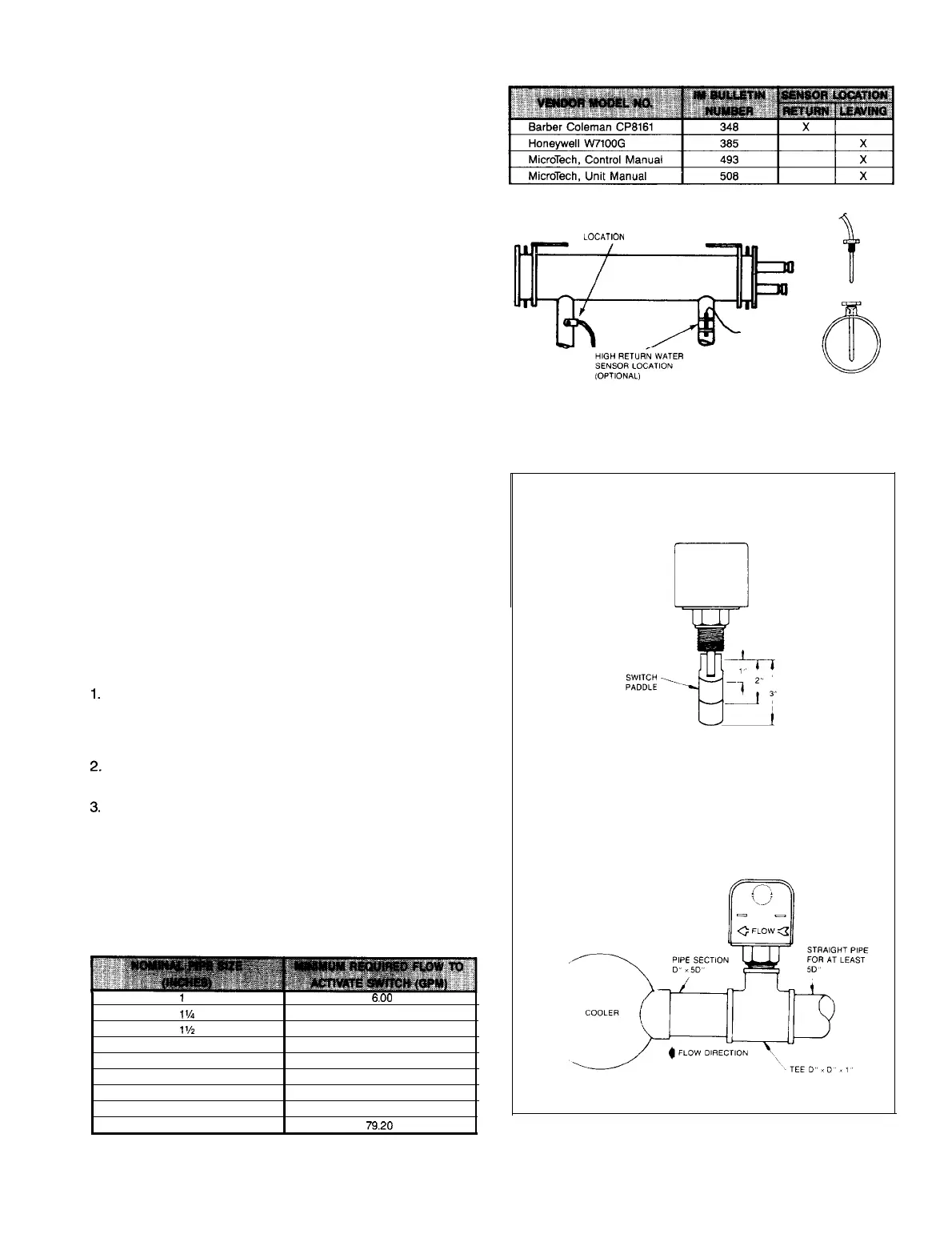

CHILLED WATER SENSOR

On units WHR-040D thru

240D.

the chilled water sensor is

factory installed in the leaving water connection on the

evaporator. For detailed specifications regarding the chilled

water sensor or any other sensors/transducers, refer to IM 493.

Care should be taken not to damage the sensor cable or lead-

wires when working around the unit. It is also advisable to

check the leadwire before running the unit to be sure that it

is firmly anchored and not rubbing on the frame or any other

Table

5.

component. Should the sensor ever be removed from the well

for servicing, care should be taken as not to wipe off the heat

conducting compound supplied in the well.

Figure 6.

Thermostat Well Installation

TEMPERATURE SENSOR

LOCATICJN

NOTE: See IM 493 for additional thermostat information.

CAUTION: The thermostat bulb should not be exposed to

water temperatures above 125°F since this will damage the

control.

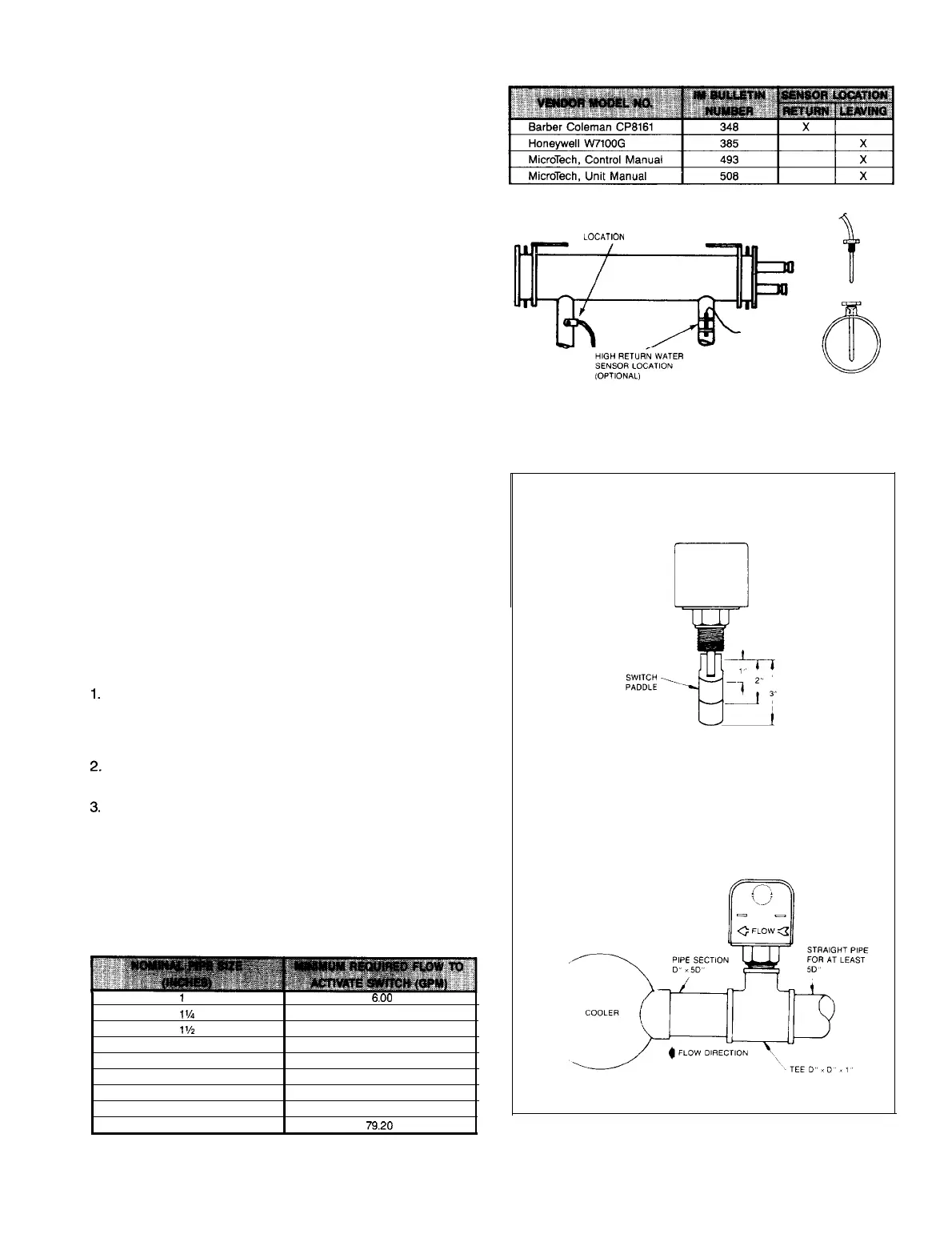

FLOW

SWITCH

A WATER FLOW SWITCH MUST SE MOUNTED in either the

entering or leaving water line to insure that there will be ade-

quate water flow and cooling load to the evaporator before

the unit can start. This will safeguard against slugging the

compressors on startup. It also serves to shut down the unit

in the event that water flow is interrupted to guard against

evaporator freeze-up.

Fioure 7.

A flow switch is available from under ordering number

1750338-00. It is a “paddle” type switch and adaptable to any

pipe size from

1”

to

6”

nominal. Certain minimum flow rates

are required to close the switch and are listed in Table 6. In-

stallation should be as shown in Figure 7. The flow switch

should be wired per actual unit wiring diagram found on the

inside of the unit control panel door or refer to IM 493.

Apply pipe sealing compound to only the threads of the

switch and screw unit into

D”x

D”x

1”

reducing tee (see

Figure

7).

The flow arrow must be pointed in the correct

direction.

Piping should provide a straight length before and after

the flow switch of at least five times the pipe diameter.

Trim flow switch paddle if needed to fit the pipe diameter.

Make sure paddle does not hang up in pipe.

CAUTION: Make sure the arrow on the side of the switch is

pointed in the proper direction of flow. The flow switch is

designed to handle the control voltage and should be con-

nected according to the wiring diagram (see wiring diagram

inside control box door).

Table 6. Flow Switch Minimum Flow Rates

1

6.00

1%

9.80

l'h 12.70

2 18.80

2%

24.30

3

30.00

4

39.70

5

58.70

FLOW SWITCH

VIEW FROM END OF COOLER

IM 508 I Page 7

Loading...

Loading...