After re-assembling the evaporator, a small amount of

refrigerant should be introduced by momentarily opening the

manual liquid line valve. A leak check should then be

per-

formed on the evaporator.

Tube removal can only take place after the leaking tube is

located. One method that would work would be to subject each

tube to

air pressure by plugging each end and, with a pressure

gauge attached to one of the end plugs, observing if there

is a loss of air pressure over a period of a minute or two.

Another method is to place a cork plug in each tube on both

ends of the cooler and applying pressure to the shell of the

cooler. After a period of time, the pressure will leak from the

shell into the leaking tube or tubes and pop out the cork plug.

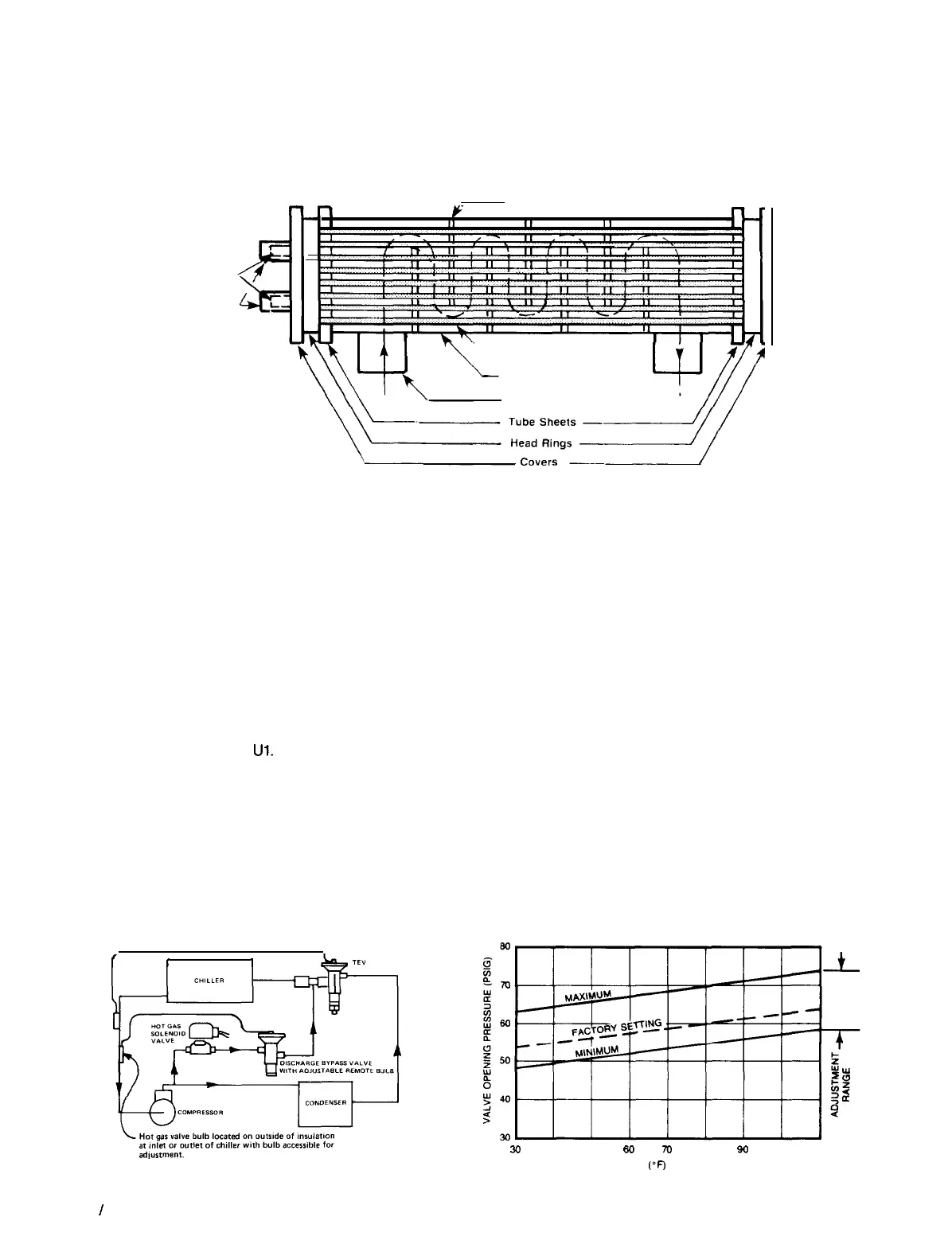

Figure

31. Top View of Typical Dual Circuit Shell-and-Tube Evaporator

Water Baffles

Liquid Connections

Suction Connections

L

Refrigerant Tubes

Shell

Water Nozzles

WATER COOLED CONDENSER

The condenser is of the shell-and-tube type with water

flow-

ment W units. Heat recovery units have integral subcoolers

ing through the tubes and refrigerant in the shell. External in the tower condensers. All condensers are equipped with

finned copper tubes are rolled into steel tube sheets. Integral 450 psig relief valves. Heat recovery condensers are free-

subcoolers are incorporated on 40 ton and larger Arrange- draining to the lower (tower) condensers and do not subcool.

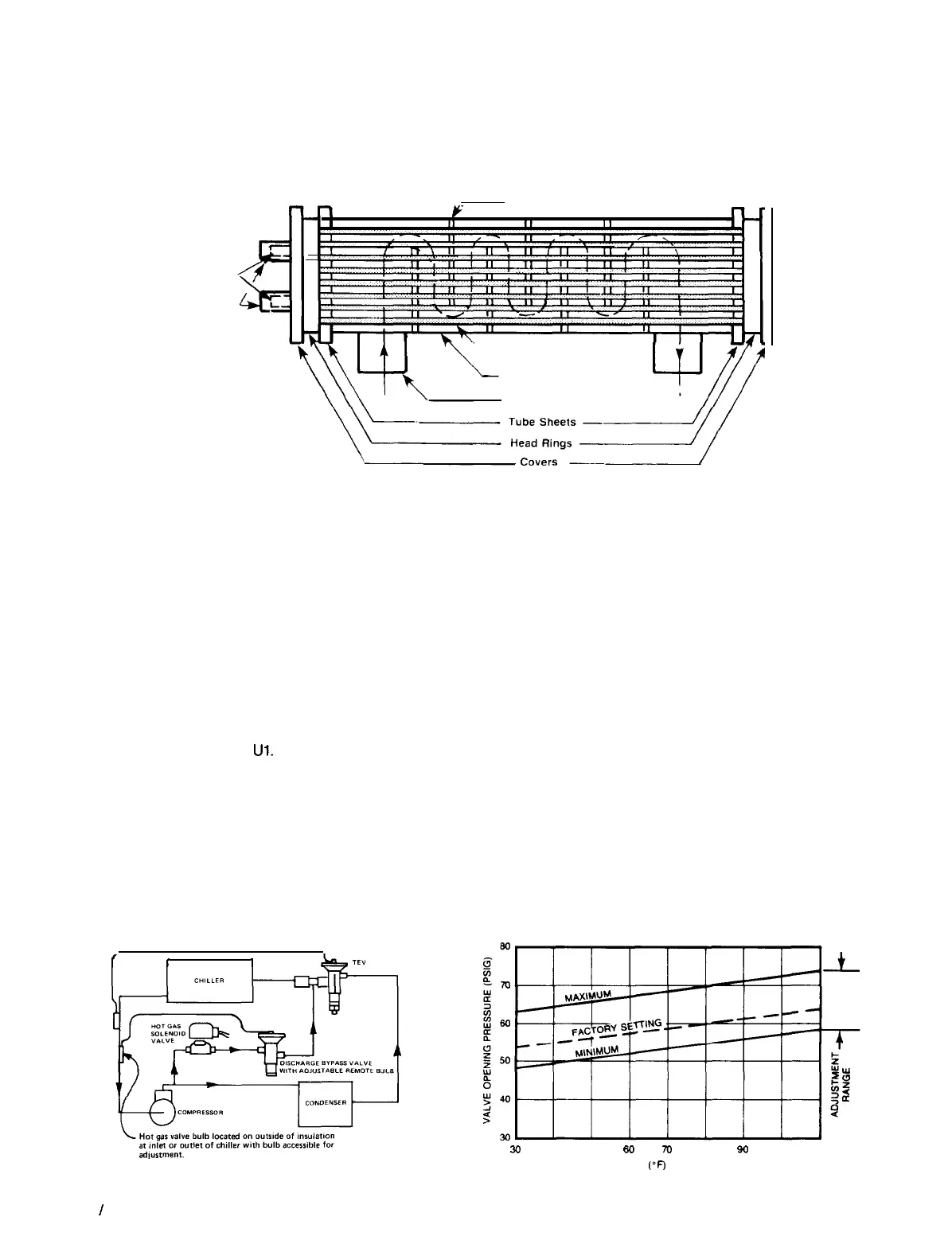

HOT GAS BYPASS (OPTIONAL)

This option allows passage of discharge gas to the evaporator

permitting operation at lower loads than available with com-

pressor unloading. It also keeps the velocity of refrigerant gas

high enough for proper oil return at light load conditions. A

solenoid valve in the hot gas bypass line is wired in parallel

with the compressor unloader

Ul.

Thus, the hot gas solenoid

cannot open unless the compressor is operating in an un-

loaded mode. If only one hot gas valve is specified for the

unit, the hot gas bypass is wired in the first refrigerant circuit

and the lead-lag switches are therefore eliminated. The hot

gas bypass option is also available for the second refrigerant

circuit whereby the lead-lag switches remain.

The pressure regulating valve is factory set to begin open-

ing at 58 psig (32°F for R-22). This setting can be changed

Figure 32.

Hot Gas Bypass Piping Diagram

f

I

I

b,

TL”

by changing the pressure of the air charge in the adjustable

bulb. To raise the pressure setting, remove the cap on the

bulb and turn the adjustment screw clockwise. To lower the

setting, turn the screw counterclockwise. Do not force the ad-

justment beyond the range it is designed for, as this will

damage the adjustment assembly.

The regulating valve opening point can be determined by

slowly reducing the system load while observing the suction

pressure. When the bypass valve starts to open, the refrigerant

line on the evaporator side of the valve will begin to feel warm

to the touch.

CAUTION: The hot gas line may become hot enough to

cause injury in a very short time; care should be taken dur-

ing valve checkout.

Figure 33. Hot Gas Bypass Adjustment Range

30

40

50

60

70

80

90

100

110

TEMPERATURE

(“F)

AT BULB LOCATION

Page 46

I

IM 508

Loading...

Loading...