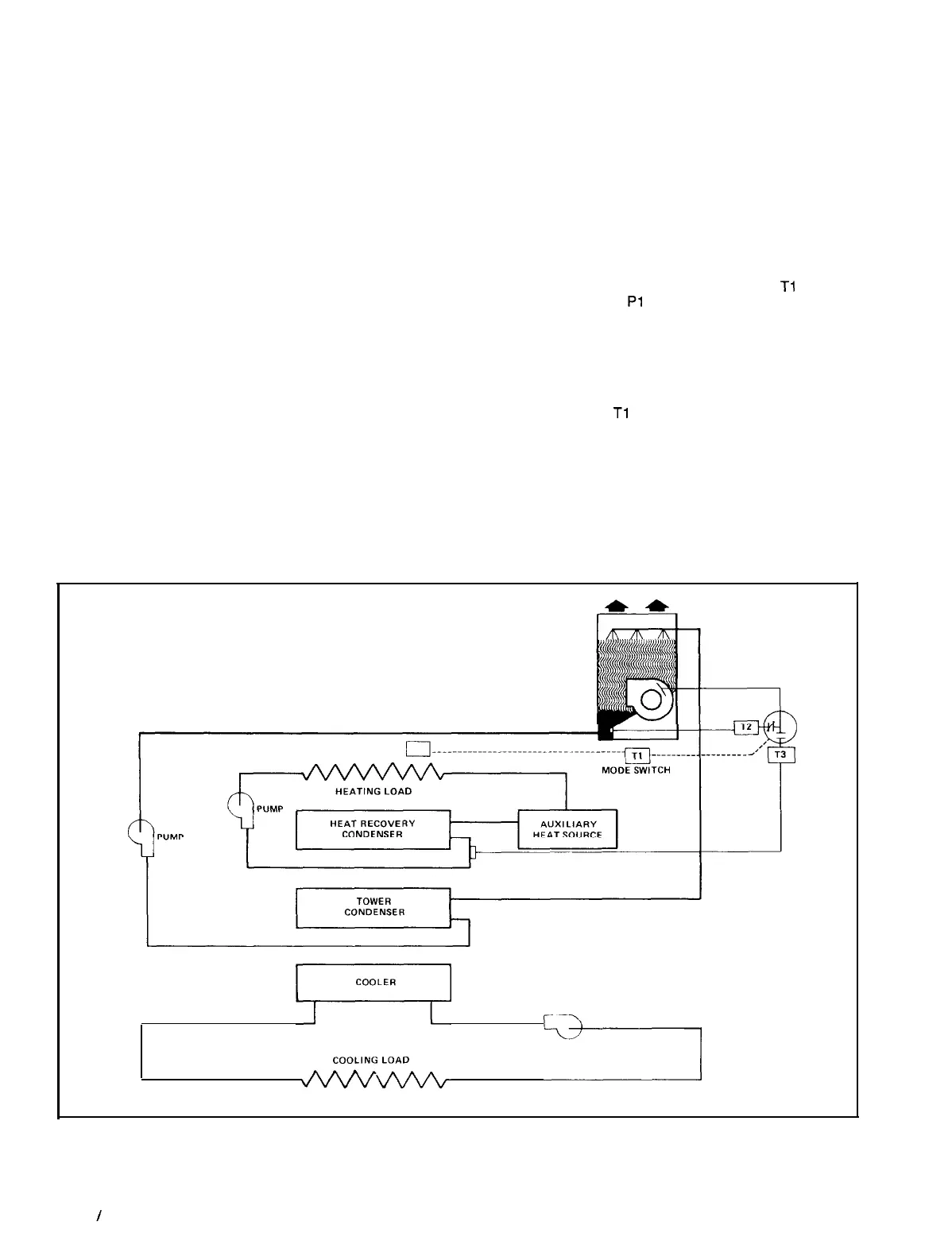

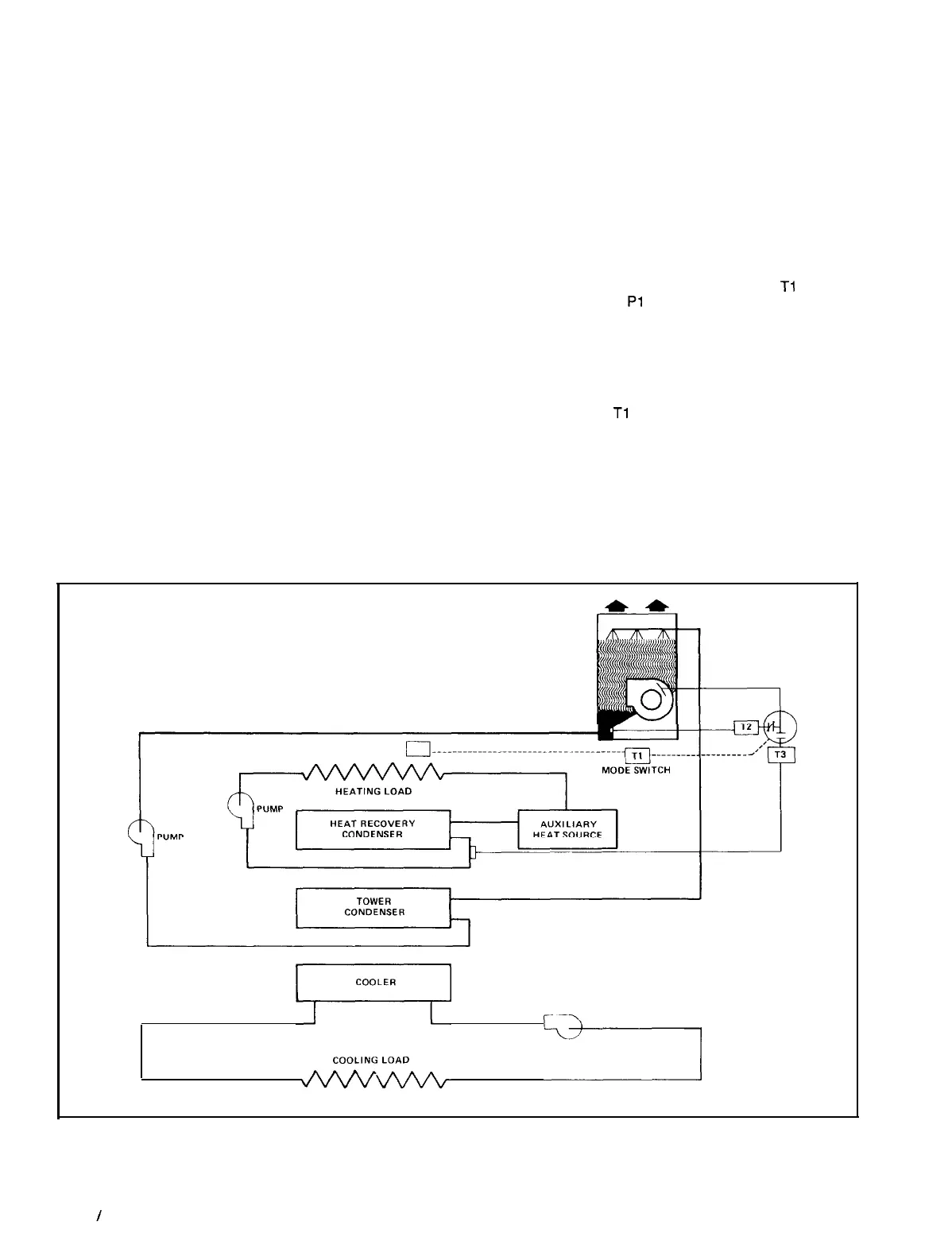

DUAL CONDENSER HEAT RECOVERY - ARRANGEMENT H

Dual condenser heat recovery chiller models have two water

cooled condensers per refrigerant circuit. The upper con-

denser is the heat recovery condenser and is piped into the

building’s hot water system. The lower condenser is the tower

condenser and is piped to an open cooling tower. Condens-

ing is done in either the tower condenser or heat recovery

condenser, or partial condensing is done in each. The tower

and heat recovery water circuits are independent and do not

intermix. This use of an open tower and the closed heat

recovery loop prevents fouling of the building’s heating

system.

A subcooling circuit is provided in the tower condenser to

provide optimum cooling efficiency. When the unit is

operating on maximum heat recovery, the cooling tower will

be modulated down to its minimum capacity, usually about

5% of full capacity. This provides subcooling for the system

during heat recovery operation. Water can be heated up to

135°F in the heat recovery condensers to satisfy a heating

load. If all of the condenser heat of rejection cannot be

used, the remainder is rejected out through the cooling tower.

The cooling tower should be sized to reject all of the con-

denser heat during summer operation. Freeze protection for

the cooling tower must be provided if it is to operate in below

freezing temperatures, Adequate capacity control must be

provided to maintain a constant water temperature leaving

the cooling tower. Head pressure and water temperature are

controlled by the tower capacity control. Fan cycling and

modulating fan discharge dampers should be used. Consult

Figure

12. Typical Dual Condenser (Per Circuit) Heat Recovery

the cooling tower manufacturer for information on specific

applications.

If the available condenser heat cannot satisfy all of the heat

load, an auxiliary heat source must be provided. The aux-

iliary heat source should be located between the heat

recovery condenser and the heat load and interlocked with

the cooling tower so that auxiliary heat is not being supplied

unless the cooling tower is modulated down all the way. The

chiller operation is always controlled by the building’s cool-

ing load and not the heating load.

TYPICAL OPERATION

-

On a call for cooling the chiller

starts. If a heating load is sensed by mode switch

Tl

, the heat

recovery water pump

Pl

will start and the cooling tower

dampers will modulate to control the heat recovery condenser

by means of proportional temperature controller T3. If max-

imum heat recovery is required, the tower dampers close and

the fans shut off. The tower will then provide

only

subcool-

ing. If more heat is required than the heat recovery con-

densers can provide, the auxiliary heat source is activated.

When mode switch

Tl

senses that a heating load no longer

exists, the heat recovery pump shuts off and the cooling tower

modulates to control the entering tower condenser water

temperature by means of proportional controller T2 and a sen-

sor located in the tower sump. Proportional controller T2 is

set at a temperature lower than T3 to provide optimum

efficiency.

COOLING TOWER

COOLER

PUMP

‘&k’

------j

NOTE: The schematic shows one refrigerant circuit. Heat recovery WHR models with two refrigerant circuits

have two heat recovery condensers and two tower condensers.

Page 12

/

IM 508

Loading...

Loading...