90-10100R30

14

GB

goh3

5

6-8

9

a

c

b

a

oh

MAINTENANCE

ohl38

PROPELLER REPLACEMENT (CONTINUED)

5

Coat the propeller shaft with Quicksilver or Mercury Precision Lubricants

Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

IMPORTANT: To prevent the propeller hub from corroding and seizing to the

propeller shaft, especially in salt water, always apply a coat of the

recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

6 If removed, insert drive pin (b) into propeller shaft.

7 Slide propeller (a) onto shaft, making sure the slot in propeller engages with

the drive pin.

8 Install the cotter pin (c) through hole in propeller and bend to hold in place.

ohk1

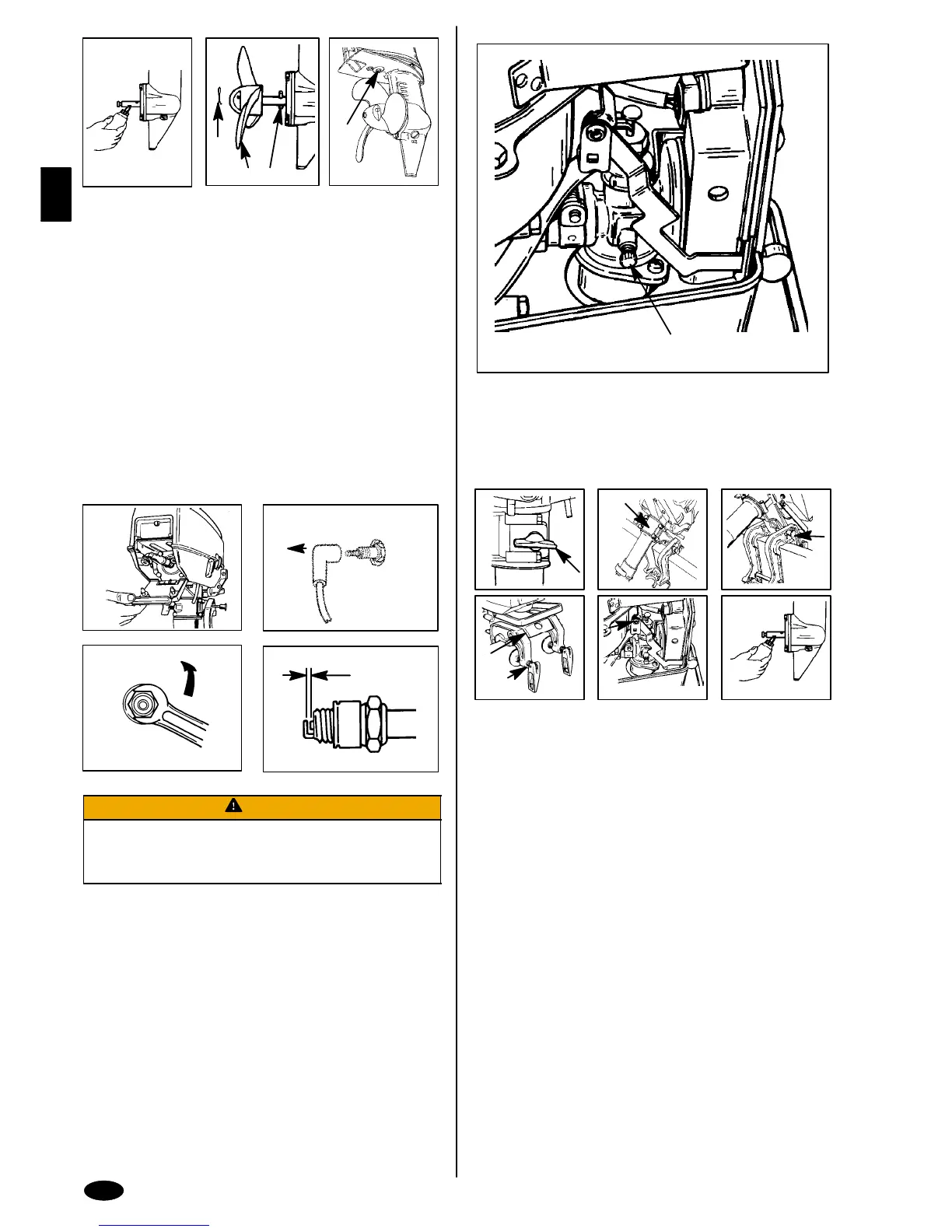

CORROSION CONTROL ANODE

Your outboard has a corrosion control anode installed to the gear case. An anode

helps protect the outboard against galvanic corrosion by sacrificing its metal to be

slowly eroded instead of the outboard metals.

9 The anode (a) requires periodic inspection especially in salt water which will

accelerate the erosion. To maintain this corrosion protection, always replace

the anode before it is completely eroded. Never paint or apply a protective

coating on the anode as this will reduce effectiveness of the anode.

2

3

4

1

ohm19

SPARK PLUG INSPECTION AND REPLACEMENT

WARNING

Avoid serious injury or death from fire or explosion caused by a dam-

aged spark plug boot (a). A damaged spark plug boot can emit sparks.

Sparks can ignite fuel vapors under the engine cowl. To avoid damag-

ing the spark plug boot, do not use any sharp object or metal tool

such as pliers, screwdriver, etc. to remove the spark plug boot.

1 Open the spark plug access door.

2 Remove the spark plug boot (a) by twisting the rubber boot slightly and pull off.

3 Remove the spark plug to inspect and clean. Replace spark plug if electrode

is worn or the insulator is rough, cracked, broken, blistered or fouled.

4 Set the spark plug gap. See Specification Chart in General Information Section.

5 Before reinstalling spark plug, clean away dirt on the spark plug seat. Install

plug finger tight, and tighten 1/4 turn or torque to 20 lb. ft. (27 N·m).

goh5

1-3

a

ohu1

ENGINE IDLE SPEED ADJUSTMENT

1 With boat tied securely to dock, start engine and allow it to warm up.

2 With outboard in forward gear, reduce engine speed to idle.

3 Adjust the idle speed screw (a) to obtain the recommended engine idle speed.

(Refer to Specification Chart in General Information Section).

goh6

1

4

3

7

6

2

5

oho63

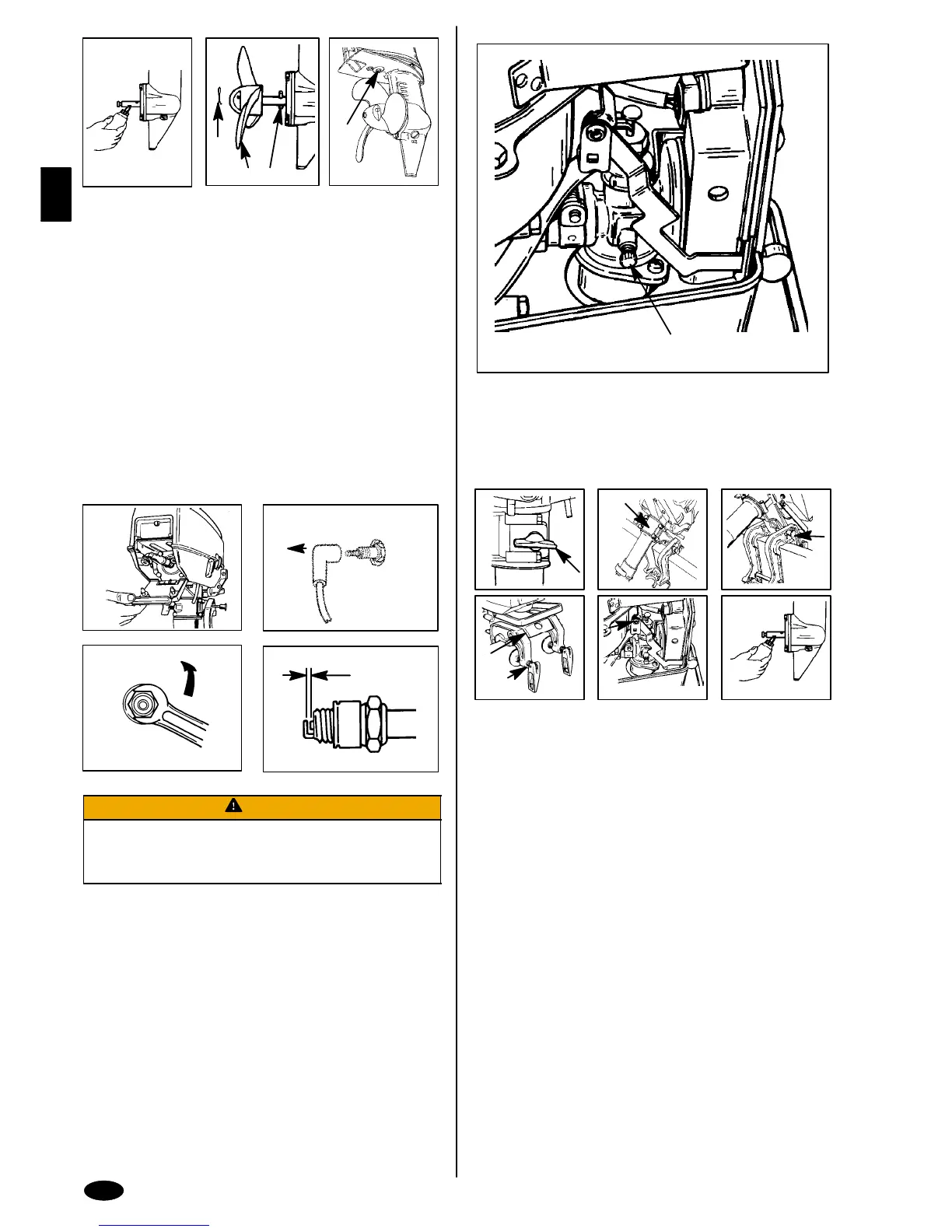

LUBRICATION POINTS

Lubricate Points 1 thru 4 with Quicksilver or Mercury Precision

Lubricants 2-4-C Marine Lubricant with Teflon or Special

Lubricate 101.

1 Co-Pilot – Lubricate threads.

2 Swivel Bracket – Remove 4 bolts and rear cover and lubricate the inner nylon

bushings.

3 Tilt Lock Pin.

4 Transom Clamp Screws – Lubricate threads.

Lubricate Points 5 and 6 with light Weight Oil

5 Tilt Pivot.

6 Throttle Linkage – Lubricate pivot point.

Lubricate point 7 with Quicksilver or Mercury Precision

Lubricants Anti-Corrosion Grease or 2-4-C Marine Lubricant with

Teflon

7 Propeller Shaft – Refer to Propeller Replacement for removal and installation

of the propeller. Coat the entire propeller shaft with lubricant to prevent the

propeller hub from corroding to the shaft.

Loading...

Loading...