MAINTENANCE

63

ob00375

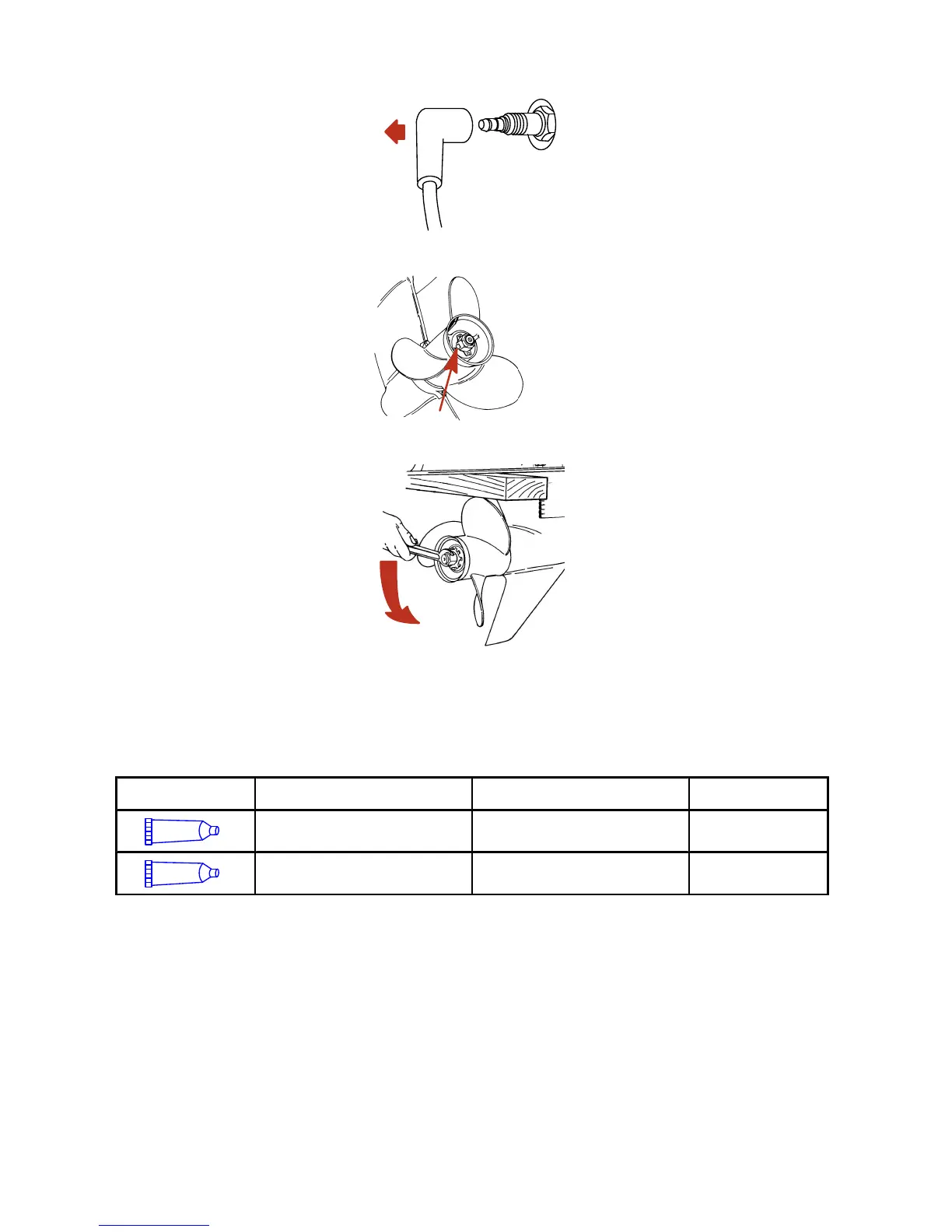

3. Straighten the bent tabs on the propeller nut retainer.

ob00376

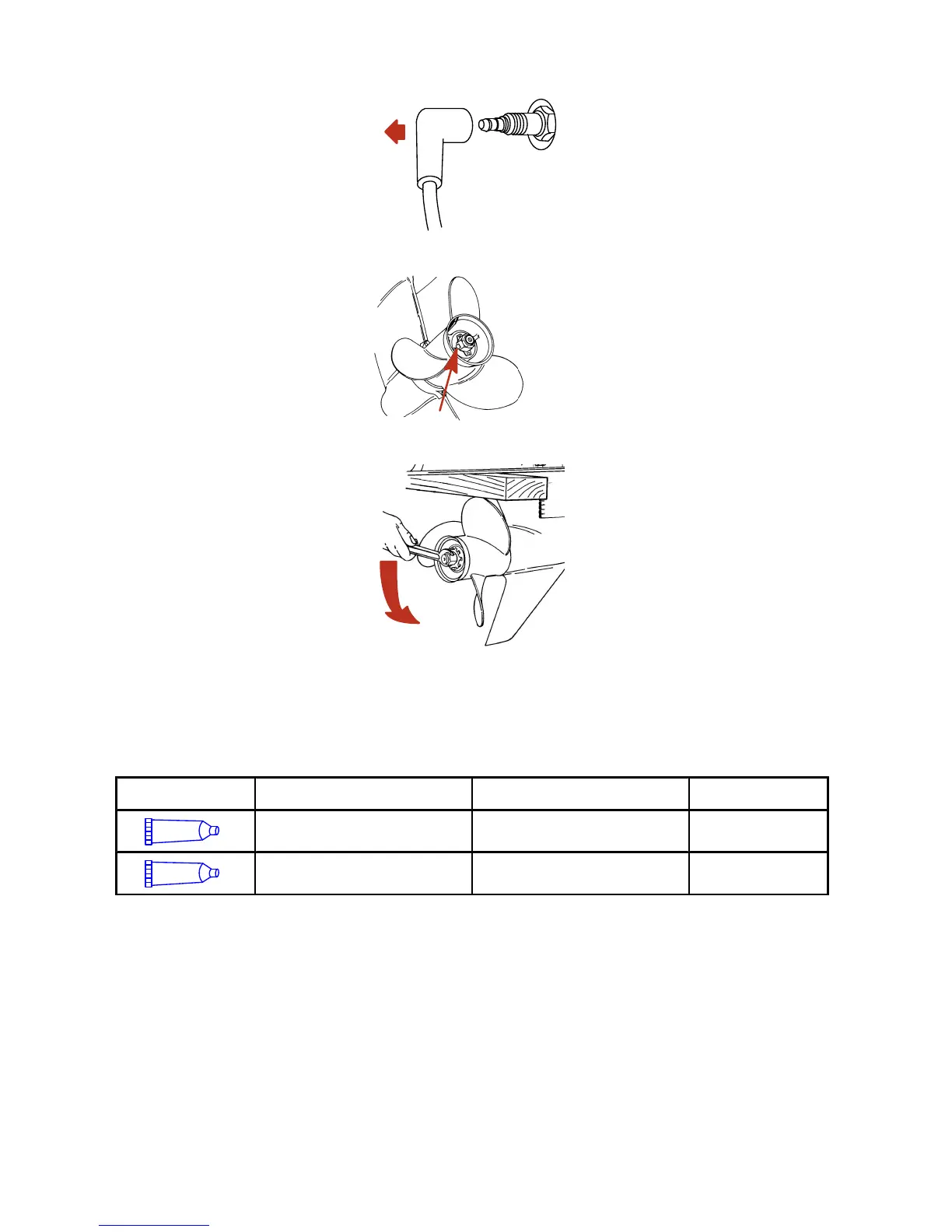

4. Place a block of wood between gearcase and propeller to hold propeller and remove propeller nut.

ob01672

5. Pull propeller straight off shaft. If propeller is seized to the shaft and cannot be removed, have the propeller

removed by an authorized dealer.

6. Coat the propeller shaft with Quicksilver or Mercury Precision Lubricants Anti‑Corrosion Grease or 2‑4‑C

with Teflon.

Tube Ref No. Description Where Used Part No.

94

Anti-Corrosion Grease Propeller shaft 92-802867Q1

95

2-4-C with Teflon Propeller shaft 92-802859Q1

IMPORTANT: To prevent the propeller hub from corroding and seizing to the propeller shaft, especially in salt

water, always apply a coat of the recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

7. Flo‑Torq I Drive Hub Propellers ‑ Install forward thrust hub, propeller, continuity washer, rear thrust hub,

propeller nut retainer, and propeller nut onto the shaft.

Loading...

Loading...