ENGLISHen

10

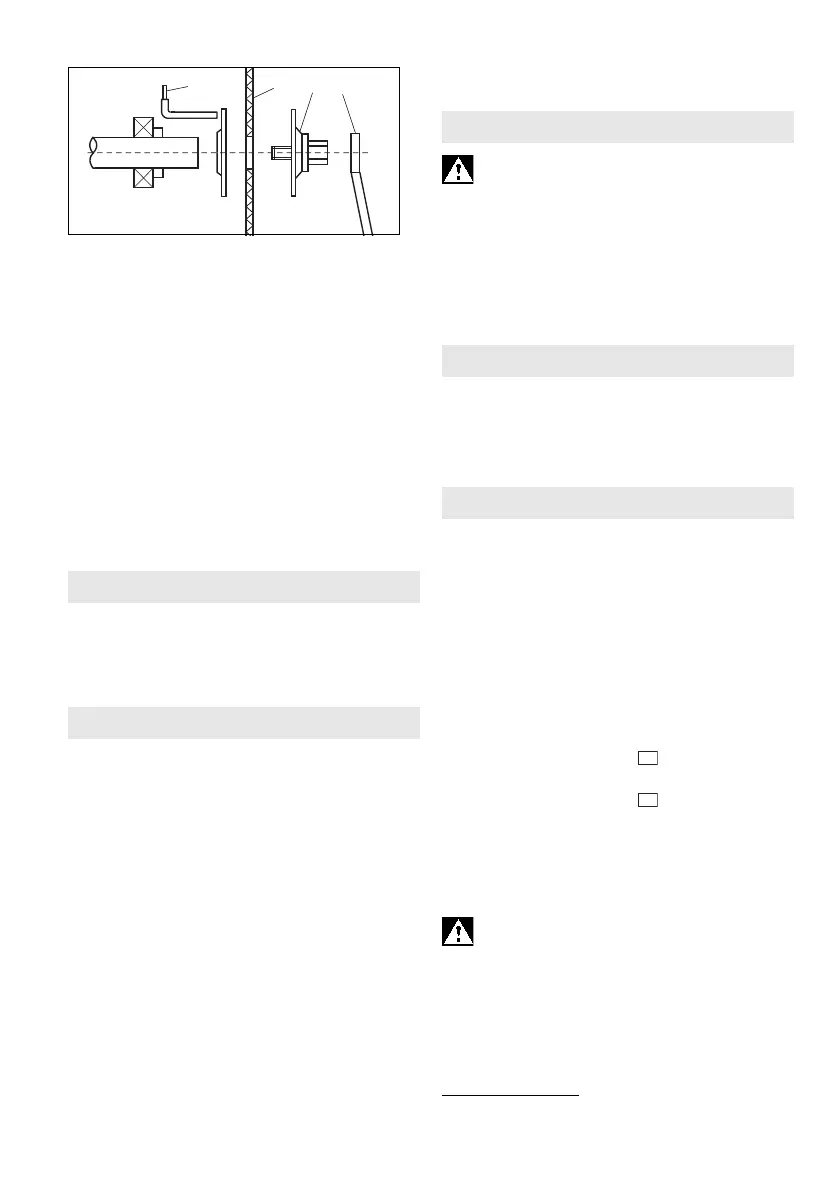

Removing the cutting disc:

- Press lever for spindle locking knob (8) to the right

and turn the cutting disc by hand until the spindle

locking knob is felt to engage.

- Use the wrench (c) to remove the screw with

clamping flange (b) anti-clockwise.

- Remove cutting disc.

Fitting the cutting disc:

- Put on new cutting disc (a).

- Fit the screw with clamping flange (b).

- Use wrench (c) to lock spindle and tighten screw

with clamping flange (b).

- Check whether the spindle locking knob (8) is

completely disengaged again.

- Clean the dirty machine and remove the grinding

dust.

Regular maintenance:

Oil the following parts at least once a month:

movable parts of the vice.

Switching on procedures produce brief reductions

in voltage. Unfavourable power conditions can be

detrimental to other devices. Power impedances

smaller than 0.2 ohm should not cause any

malfunction.

Use only genuine Metabo accessories.

If you need any accessories, check with your

dealer.

For dealers to select the correct accessory, they

need to know the exact model designation of your

power tool.

See page 4.

A Cutting discs: Quality class A 24-M "Original

Cutting"

Aluminum oxide wheels for general purpose

use on steel and other ferrous metals larger

chop saw applications. Excellent rate of cut.

Good wheel life.

B Cutting discs: Quality class A 30-S "LongLife

Original "

Aluminum oxide wheels specially formulated for

dry wall stud applications. Good rate of cut.

Good wheel life.

C Cutting discs: Quality class A 30-R "LongLife

Original"

Aluminum oxide wheels for general purpose

use on steel and other ferrous metals.

Good rate of cut. Good wheel life.

For a complete range of accessories, see

www.metabo.com or the main catalogue.

Repairs to electrical tools must be carried out

by qualified electricians ONLY!

A defective mains cable must only be replaced with

a special, original mains cable from metabo, which

is available only from the Metabo service.

If you have Metabo electrical tools that require

repairs, please contact your Metabo service centre.

For addresses see www.metabo.com.

You can download spare parts lists from

www.metabo.com.

The generated grinding dust may contain harmful

substances. Dispose appropriately.

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

Explanatory notes on the specifications on page 4.

Changes due to technological progress reserved.

U=Voltage

I = Current

P

1

=Rated input

P

2

=Power output

n

0

=No load speed

Cutting disc dimensions:

D

max

=Maximum outer diameter

B =Wheel thickness

d =Bore

H

max 90°

=Max. cut diameter

( = rod,

= pipe, = section steel)

H

max 45°

=Max. cut diameter

( = rod,

= pipe, = section steel)

L

max

=Max. vice opening

m =Weight without mains cable

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

Emission values

These values make it possible to assess the

emissions from the power tool and to compare

different power tools. Depending on the operating

conditions, the condition of the power tool or the

accessories, the actual load may be higher or lower.

For assessment purposes, please allow for breaks

and periods when the load is lower. Based on the

adjusted estimates, arrange protective measures

for the user e.g. organisational measures.

Vibration total value

(vector sum of three directions)

determined in accordance with EN 62841:

a

hw

= Vibration emission value

K

hw

= Uncertainty (vibration)

8. Troubleshooting

9. Accessories

10. Repairs

11. Environmental Protection

12. Technical Specifications

Loading...

Loading...