Do you have a question about the Metso NELES NDX2512TG and is the answer not in the manual?

Covers general safety warnings, cautions, and notes regarding hazards and operation.

Details specific safety requirements for hazardous areas (Ex).

Details explosion hazard warnings for different hazardous area classifications.

Lists ATEX, IECEx, CSA, and UL certifications with electrical values and temp ranges.

Guidelines for installing NDX on generic linear actuators, focusing on magnet positioning.

Details distance tolerances and exclusion zones for optimal magnet alignment.

Guidelines for installing NDX on generic rotary actuators, focusing on magnet alignment.

Details input values and hazardous area connection requirements.

Explains the guided startup process for device setup and calibration.

Details manual, 1-point, and automatic calibration procedures.

Describes automatic calibration and parameter configuration (Language, Actuator Type, Valve Type, Dead Angle).

Configures fail action and performance level for valve control.

Explains how to restrict LUI access for secure operation.

Emphasizes the need for configuration and calibration before automatic control.

Corrects linkage geometry for linear valves using 3-point calibration.

Introduces DTM and FDT standard for field device management and integration.

Explains the DTM user interface elements and their functions.

Tools for checking device state, commissioning, and configuring behavior.

DTM guided start-up for device commissioning.

Details diagnostics for travel ratio, steady state deviation, hunting, and operation states.

Lists diagnostic statuses for relay valve travel, operation time, supply pressure, setpoint, prestage, and calibration.

Covers diagnostics for missing feedback magnet, actuator pressure sensor, electronics, and failsafe.

Details diagnostics for valve travel, reversals, position, stiction, and opening load.

Covers diagnostics for control ratio, temperature, supply pressure, and limit switch statuses.

Lists alert limits for valve travel, reversals, position, stiction, and opening load.

Configures performance, instrumentation, and pneumatic connections.

Introduces diagnosis tools and explains performance monitoring.

Describes the three NDX DTM user interfaces: Offline, Online, and Diagnosis.

Details device status classification and device information parameters.

Configuration of device statuses and related events according to NAMUR class.

Details device info and assembly parameters like fail action, actuator type, valve type.

Covers software requirements and installation/update procedures for DTM.

General requirements and safety warnings for maintenance.

Covers general safety warnings, cautions, and notes regarding hazards and operation.

Details specific safety requirements for hazardous areas (Ex).

Details explosion hazard warnings for different hazardous area classifications.

Lists ATEX, IECEx, CSA, and UL certifications with electrical values and temp ranges.

Guidelines for installing NDX on generic linear actuators, focusing on magnet positioning.

Details distance tolerances and exclusion zones for optimal magnet alignment.

Guidelines for installing NDX on generic rotary actuators, focusing on magnet alignment.

Details input values and hazardous area connection requirements.

Explains the guided startup process for device setup and calibration.

Details manual, 1-point, and automatic calibration procedures.

Describes automatic calibration and parameter configuration (Language, Actuator Type, Valve Type, Dead Angle).

Configures fail action and performance level for valve control.

Explains how to restrict LUI access for secure operation.

Emphasizes the need for configuration and calibration before automatic control.

Corrects linkage geometry for linear valves using 3-point calibration.

Introduces DTM and FDT standard for field device management and integration.

Explains the DTM user interface elements and their functions.

Tools for checking device state, commissioning, and configuring behavior.

DTM guided start-up for device commissioning.

Details diagnostics for travel ratio, steady state deviation, hunting, and operation states.

Lists diagnostic statuses for relay valve travel, operation time, supply pressure, setpoint, prestage, and calibration.

Covers diagnostics for missing feedback magnet, actuator pressure sensor, electronics, and failsafe.

Details diagnostics for valve travel, reversals, position, stiction, and opening load.

Covers diagnostics for control ratio, temperature, supply pressure, and limit switch statuses.

Lists alert limits for valve travel, reversals, position, stiction, and opening load.

Configures performance, instrumentation, and pneumatic connections.

Introduces diagnosis tools and explains performance monitoring.

Describes the three NDX DTM user interfaces: Offline, Online, and Diagnosis.

Details device status classification and device information parameters.

Configuration of device statuses and related events according to NAMUR class.

Details device info and assembly parameters like fail action, actuator type, valve type.

Covers software requirements and installation/update procedures for DTM.

General requirements and safety warnings for maintenance.

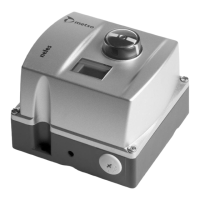

| Brand | Metso |

|---|---|

| Model | NELES NDX2512TG |

| Category | Controller |

| Language | English |