Loading...

Loading...

Do you have a question about the MG Midget and is the answer not in the manual?

| Brand | MG |

|---|---|

| Model | Midget |

| Category | Automobile |

| Language | English |

Overview of the chassis, its components, and general mechanical details.

Guidance on oils and greases for various car components.

Oil recommendations and maintenance for gearbox and rear axle.

Explanation of the steering layout, design, and lubrication.

Detailed information on the brake system, application, and adjustments.

How to adjust brakes individually for each wheel.

Operation, adjustment, and maintenance of the clutch system.

Instructions for adjusting and maintaining shock absorbers.

Details the process of removing carbon deposits from the engine.

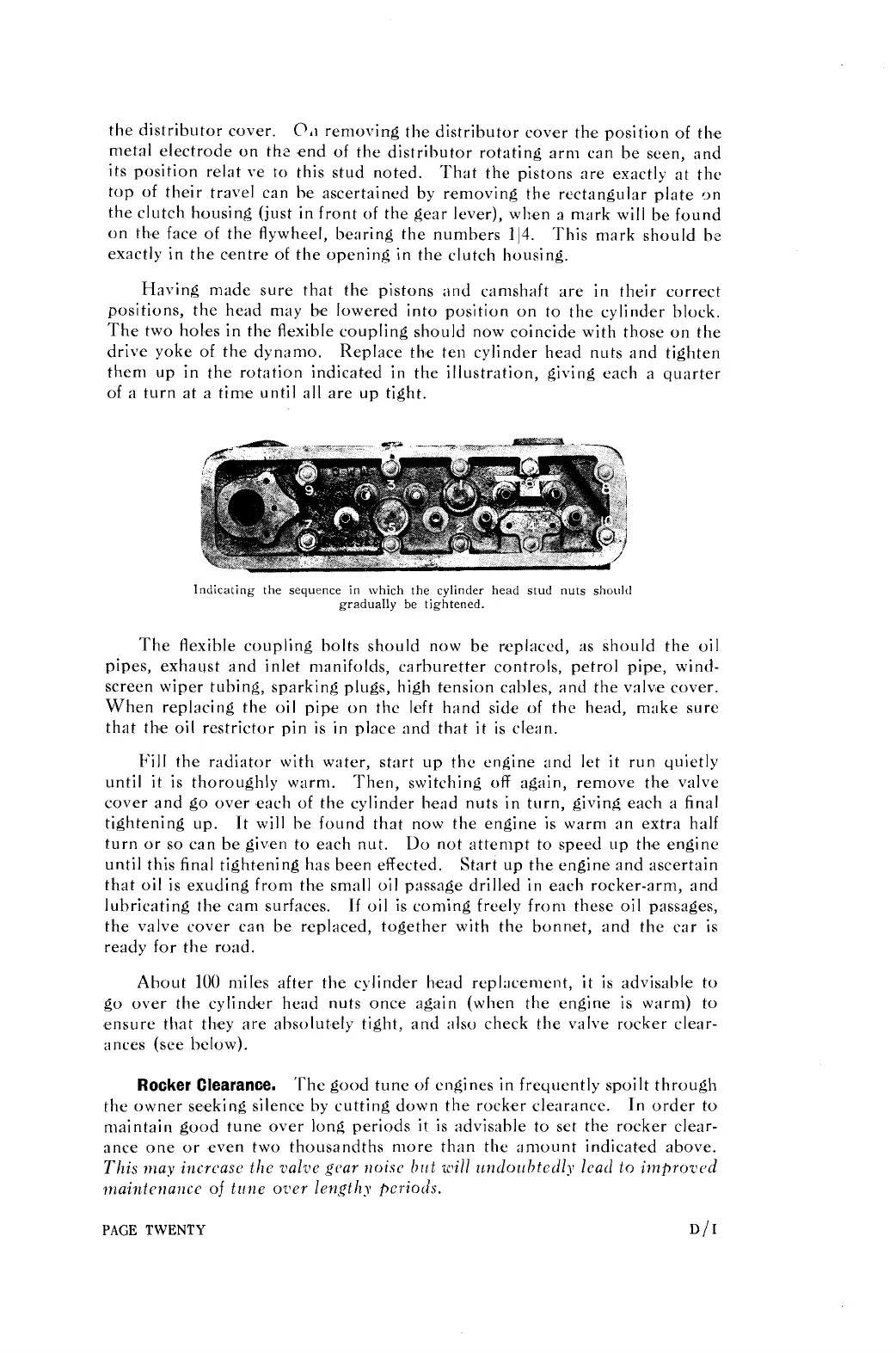

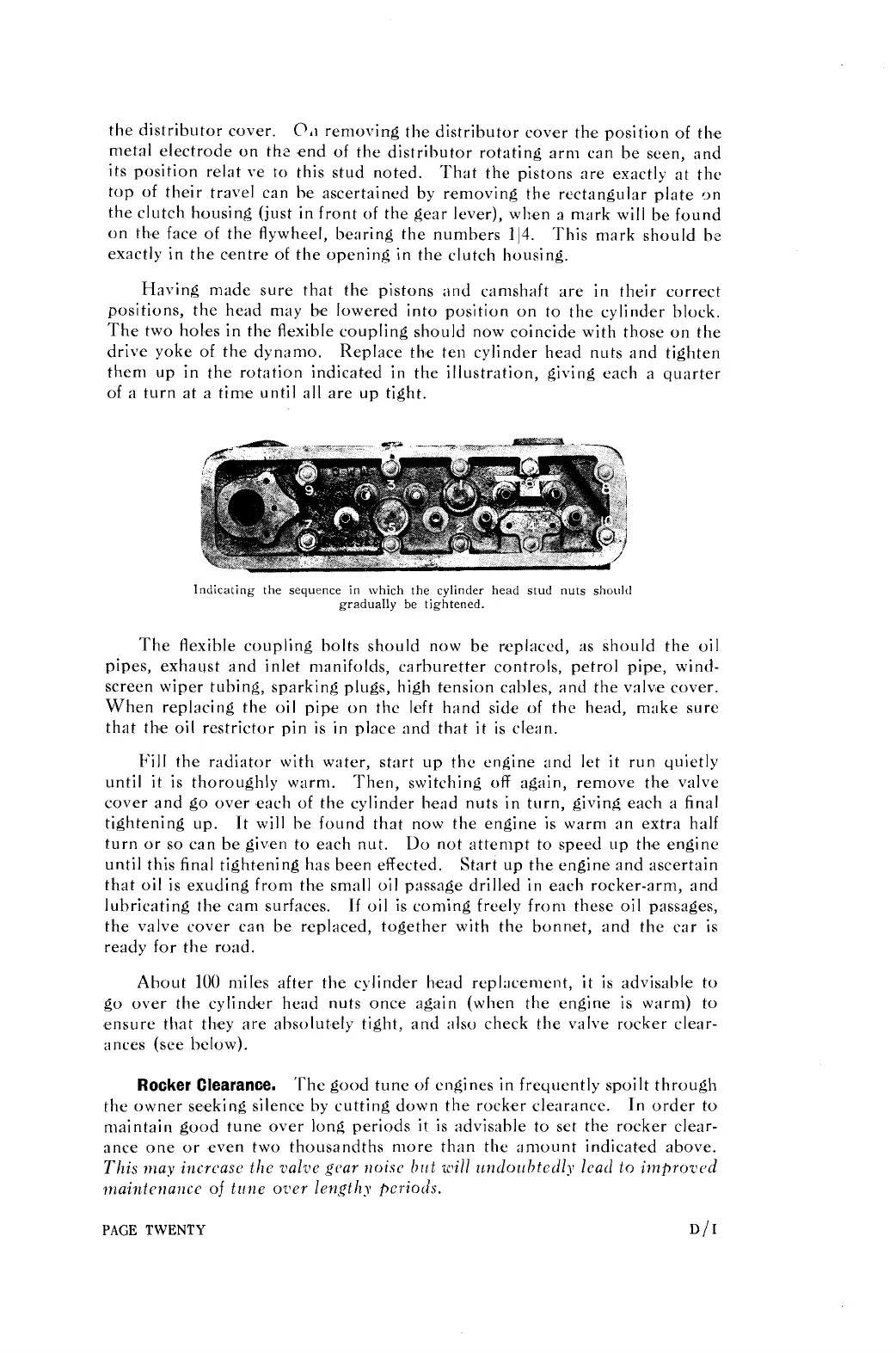

Instructions for removing, grinding, and reassembling engine valves.

Information regarding the care and maintenance of engine bearings.

Details on the distributor, coil, and associated components.

Troubleshooting guide for ignition failures and misfiring.

Information on headlamp adjustment, wiring, and cleaning.

Maintenance and troubleshooting for the car's electric horn.

Operation, troubleshooting, and maintenance of the S.U. petrol pump.

Explanation of the carburettor's function and components.

Steps for adjusting the carburettor for optimal engine performance.

Common issues affecting carburettor function and their remedies.

Advice on body maintenance, door adjustments, and access points.

Location and access to the car's fuel tank.

Details on the folding luggage platform and its operation.

Information on the location and mounting of the spare wheel.

Instructions for operating and securing the bonnet fasteners.

Guidance on tyre maintenance, pressure checks, and fitting.

List of service centres for electrical and related equipment.

Directory of authorised service and sales agents across regions.