MLCAC-UTSM-2010-10 Insulation Work

Installation 123

5. Insulation Work

5.1 Insulation material and thickness

1). Insulation material

Insulation material should adopt the material which is able to endure the pipe’s temperature: no less than 70 in the high℃ -pressure side, no

less than 120 in the low℃ -pressure side(For the cooling type machine, no requirements at the low-pressure side.)

Example: Heat pump type----Heat-resistant Polyethylene foam (withstand above 120 )℃

Cooling only type---- Polyethylene foam (withstand above 100 ) ℃

2). Thickness choice for insulation material

Insulation material thickness is as follows:

Pipe diameter (mm) Adiabatic material thickness

Refrigerant pipe

Φ6.4—Φ25.4 10mm

Φ28.6—Φ38.1 15mm

Drainage pipe

Inner diameterΦ20—Φ32 6mm

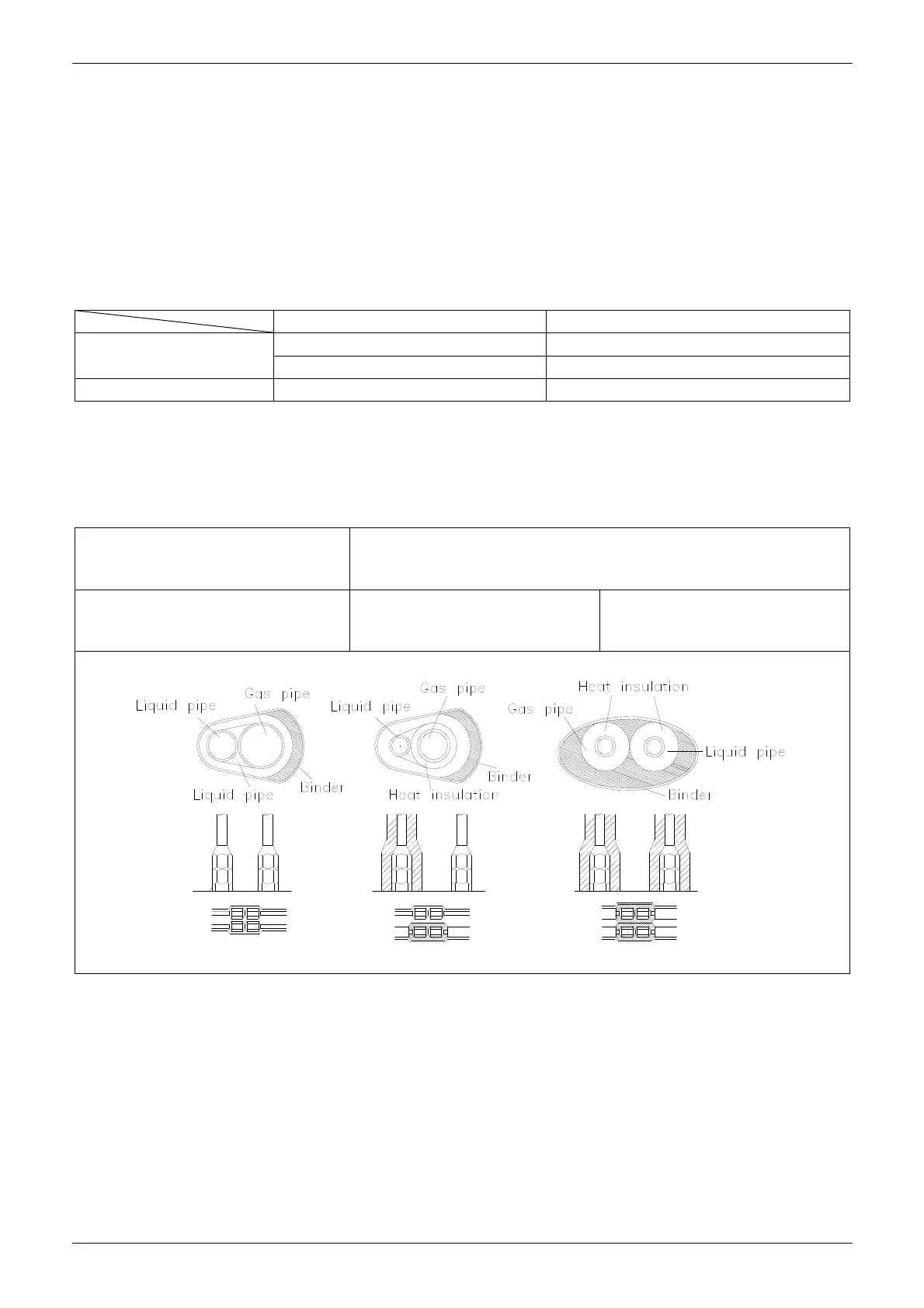

5.2 Refrigerant pipe insulation

1). Work Procedure

Before laying the pipes, the non① -jointing parts and non-connection parts should be heat insulated.

When the gas proof test is eligible, the jointing area, expanding area and the flange area should be heat insulated②

2). Insulation for non-jointing parts and non-connection parts

wrong right

Gas pipe and liquid pipe should

not be put together to insulate

Insulate the gas pipe

(cooling only)

Insulate the gas pipe and

liquid pipe

Loading...

Loading...