Do you have a question about the Migatronic AUTOMIG2 i and is the answer not in the manual?

| Mains voltage | 3 x 400 V |

|---|---|

| Mains frequency | 50/60 Hz |

| Mains fuse | 16 A |

| Open circuit voltage | 16-36 V |

| Protection class | IP21S |

| Wire Diameter | 0.6-1.0 mm |

| Standards | EN/IEC 60974-1, EN/IEC 60974-10 |

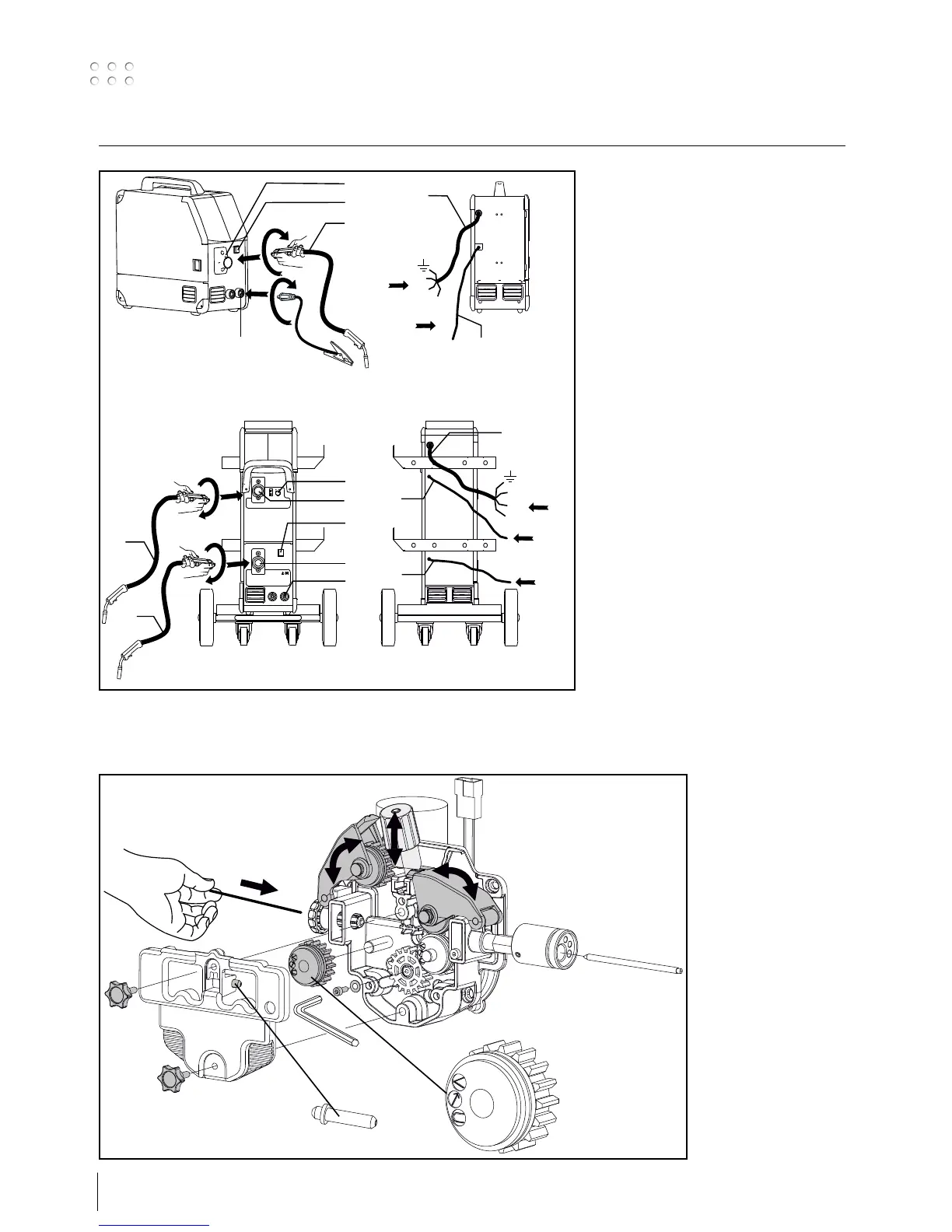

Steps for unpacking the welding machine and preparing it for use.

Instructions for connecting the welding hose to the machine.

Procedure for connecting the machine to the power supply.

Details on assembling the parts within the wire feed unit.

Procedure for adjusting the wire brake for proper wire reel tension.

Guide to identifying and resolving machine errors based on error codes.

Detailed technical specifications for different AUTOMIG2 models.