11

en

3. Installing the hydro unit

3.1. Checking the accessories with the hydro

unit

The following items are supplied with each hydro unit.

3.2. Installing hydro units

Bases

• Be sure to install unit in a place strong enough to withstand its weight. If the base

is unstable, reinforce with a concrete base.

• The unit must be anchored on a level surface. Use a level to check after installation.

• If the unit is installed near a room where noise is a problem, using an anti-

vibration stand on the base of the unit is recommended.

[Fig. 3.2.1] (P.3)

• Be sure to install unit in a place strong enough to withstand its weight.

Any lack of strength may cause unit to fall down, resulting in a personal injury.

• Have installation work in order to protect against earthquake.

Any installation deficiency may cause unit to fall down, resulting in a

personal injury.

Be sure to install the hydro unit horizontally. Check using a level. If the

unit is installed at an angle, drain water may leak out.

• Be sure to install the unit horizontally.

Install the hydro unit level (less than 1° tilt), so that the drain pan (option)

can function correctly.

4. Connecting refrigerant pipes and drain pipes

4.1. Connecting refrigerant pipes

1. Be sure to use non-oxidative brazing where necessary. If you do not use non-

oxidative brazing, it may clog the pipes.

When brazing the outdoor unit connecting port of hydro unit, supply nitrogen gas

into the pipe between the outdoor unit and hydro unit.

2. After completing pipe connection, support the pipes to ensure that load is not

imparted to the hydro unit’s end connections.

3. When using mechanical couplings, use the ones that meet ISO14903.

When installing and moving the unit, do not charge it with refrigerant other

than the refrigerant (R32) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to

malfunction and result in severe damage.

• Use refrigerant piping made of phosphorus deoxidized copper and copper

alloy seamless pipes and tubes. In addition, be sure that the inner and outer

surfaces of the pipes are clean and free of hazardous sulphur, oxides, dust/

dirt, swarf, oils, moisture, or any other contaminants.

- R32 is high-pressure refrigerant and can cause the existing piping to burst.

• Store the piping to be used during installation hydro unit and keep both

ends of the piping sealed until just before brazing. (Store elbows and other

joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

- Infiltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

• Do not vent R32 into the atmosphere.

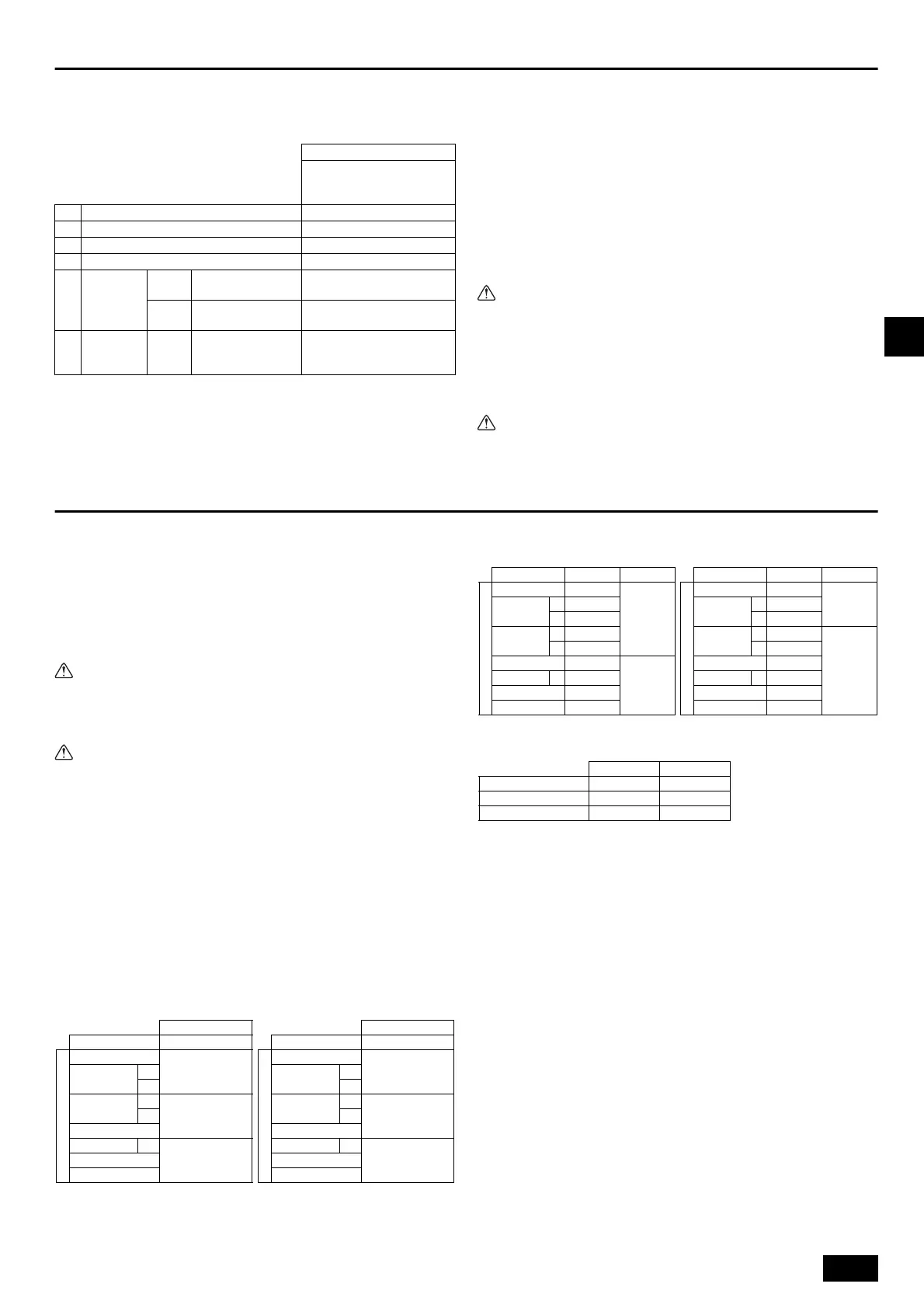

1. Size of hydro unit’s end connection piping

[Fig. 4.1.1] (P.3)

Note:

• Be sure to use non-oxidative brazing.

<Refrigerant piping connection examples>

• Obtain joints and elbows on site as necessary according to the pipe diameter,

and connect the pipes as shown in the figures below.

[Fig. 4.1.2] (P.4)

(1) When routing the pipes through the front of the unit

(2) When routing the pipes through the bottom of the unit

(3) Pipe connection port and connecting pipe

Model name

CMH-WM250V-A

CMH-WM350V-A

CMH-WM500V-A

Item Qty

1 Installation manual 1

2 Air vent manual 1

3 Auto air vent valve (3/4 parallel thread) 1

4

Strainer

(20 mesh)

W250

W350

32A screw-in

housing (40A)

1

W500

40A screw-in

housing (50A)

1

5

Refrigerant

connection

pipe

W350

W500

ø25.4 –ø28.58

(ø1 – ø1-1/8)

1

A M10 anchor bolt (not supplied)

B (Incorrect installation) The corner section is not securely received.

C Fixing bracket for post-installed anchor bolts (not supplied) (To be fixed with three screws)

D Anti-vibration rubber pad (The pad needs to be large enough to cover the entire width of

each unit leg.)

1. Hydro units connectable to outdoor units

Standard models High-efficient models

Hydro unit

Unit model Model name

Outdoor unit side

PUHY-M200

CMH-

WM250V-A

PUHY-M250

*1

*2

PUHY-M300

*3

CMH-

WM350V-A

*4

PUHY-M350

PUHY-M400 *5

CMH-

WM500V-A

PUHY-M450

PUHY-M500

Hydro unit

Unit model Model name

Outdoor unit side

PUHY-EM200

CMH-

WM250V-A

PUHY-EM250

*1

*2

PUHY-EM300

*3

CMH-

WM350V-A

*4

PUHY-EM350

PUHY-EM400 *5

CMH-

WM500V-A

PUHY-EM450

PUHY-EM500

*1 When the piping length from the outdoor unit to the hydro unit is less than 90 m (295 ft)

*2 When the piping length from the outdoor unit to the hydro unit is 90 m (295 ft) or more

*3 When the piping length from the outdoor unit to the hydro unit is less than 40 m (131 ft)

*4 When the piping length from the outdoor unit to the hydro unit is 40 m (131 ft) or more

*5 When the unit is used alone

A To outdoor unit

B End connection (brazing)

C Hydro unit

D To ma in pipin g

E Indoor unit

<A> Liquid side A Refrigerant piping

<B> Gas side B Elbow

C On-site piping

2. Connecting pipe diameter of outdoor unit

Standard models High-efficient models

Unit model Liquid Gas

Outdoor unit side

PUHY-M200

ø9.52 (ø3/8)

ø22.2

(ø7/8)

PUHY-M250

*1

ø9.52 (ø3/8)

*2

ø12.7 (ø1/2)

PUHY-M300

*3

ø9.52 (ø3/8)

*4

ø12.7 (ø1/2)

PUHY-M350

ø12.7 (ø1/2)

ø28.58

(ø1-1/8)

PUHY-M400

*5

ø12.7 (ø1/2)

PUHY-M450

ø15.88 (ø5/8)

PUHY-M500

ø15.88 (ø5/8)

Unit model Liquid Gas

Outdoor unit side

PUHY-EM200

ø9.52 (ø3/8)

ø22.2

(ø7/8)

PUHY-EM250

*1

ø9.52 (ø3/8)

*2

ø12.7 (ø1/2)

PUHY-EM300

*3

ø9.52 (ø3/8)

ø28.58

(ø1-1/8)

*4

ø12.7 (ø1/2)

PUHY-EM350

ø12.7 (ø1/2)

PUHY-EM400

*5

ø12.7 (ø1/2)

PUHY-EM450

ø15.88 (ø5/8)

PUHY-EM500

ø15.88 (ø5/8)

3. Connecting pipe diameter of hydro unit

If the connecting pipe diameter of hydro unit differs from that of outdoor unit, expand

or reduce the pipe diameter at the inlet of the hydro unit.

Liquid Gas

CMH-WM250V-A ø9.52 (ø3/8) ø22.2 (ø7/8)

CMH-WM350V-A ø12.7 (ø1/2) ø25.4 (ø1)

CMH-WM500V-A ø15.88 (ø5/8) ø25.4 (ø1)

WT09052X01_en.book 11 ページ 2019年1月17日 木曜日 午前10時49分

Loading...

Loading...