8-3

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Damper - Inspect

Damper - Check visually

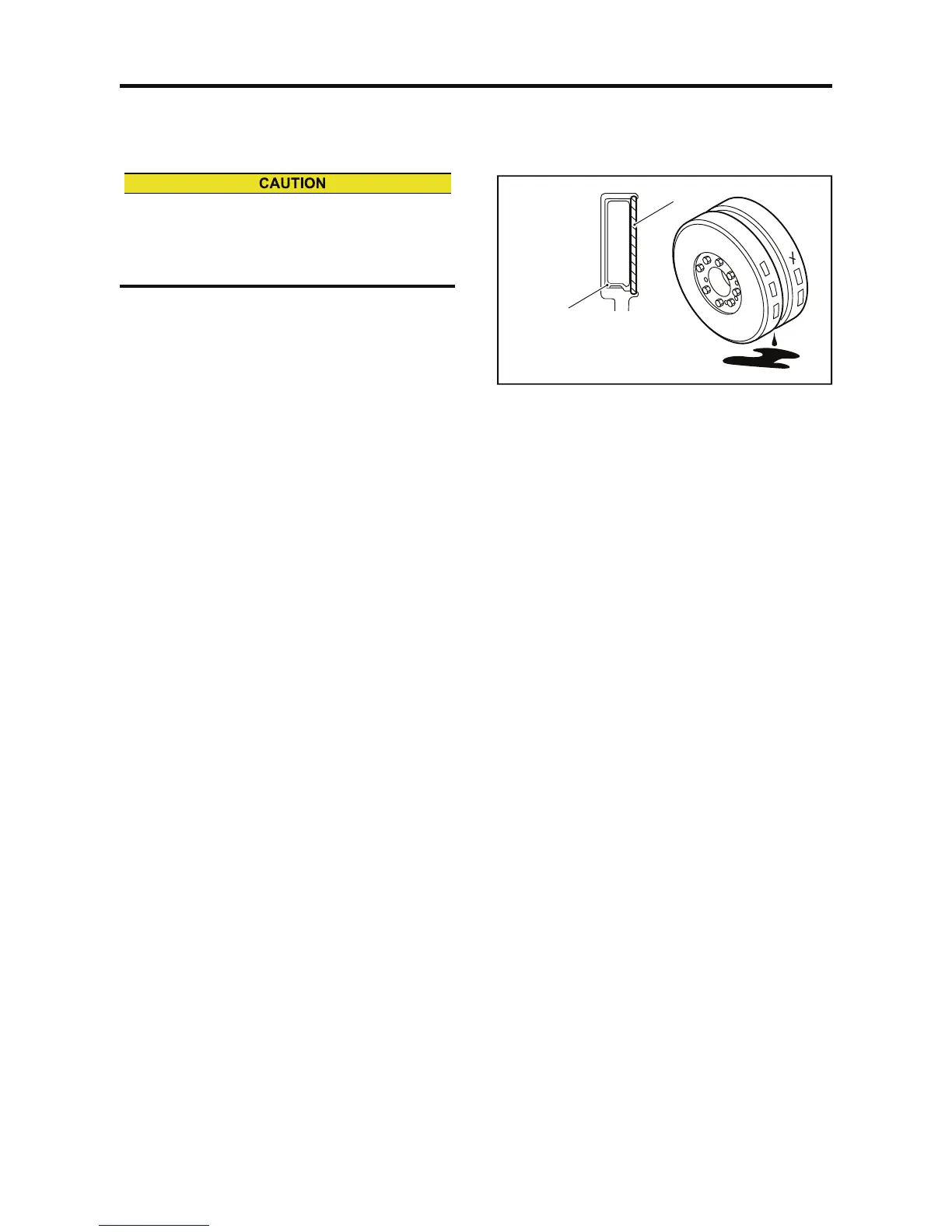

Check the vibration damper for oil leakage, scratches,

deformation, discoloration and peeling of paint. Check

carefully for swelling on the cover (use a scale), oil

leaks from the shim, discoloration and peeling of paint

due to heat.

Note: If defects are found in the damper, contact a

dealer of Mitsubishi Heavy Industries, Ltd.

Fig. 8-2 Damper - Check visually

Damper temperature management

For making damper function well, heat of damper must be dissipated from its surface to prevent excessive damper

heating. Mitsubishi Heavy Industries, Ltd. inspects each engine before shipment to ensure proper operating temper-

ature of the vibration damper. However, the vibration damper temperature varies depending on ambient conditions.

Therefore, observe the following suggestions and provide sufficient ventilation for the vibration damper and equip-

ment.

1. Make sure the temperature of the outside damper surface does not exceed 90 °C [194 °F] when operating the

engine with rated power for an hour.

2. When installing a safety cover to damper, check ventilation carefully and make sure the damper temperature re-

mains below 90 °C [194 °F], with the cover in place.

3. It is recommended to use the thermo label for temperature management.

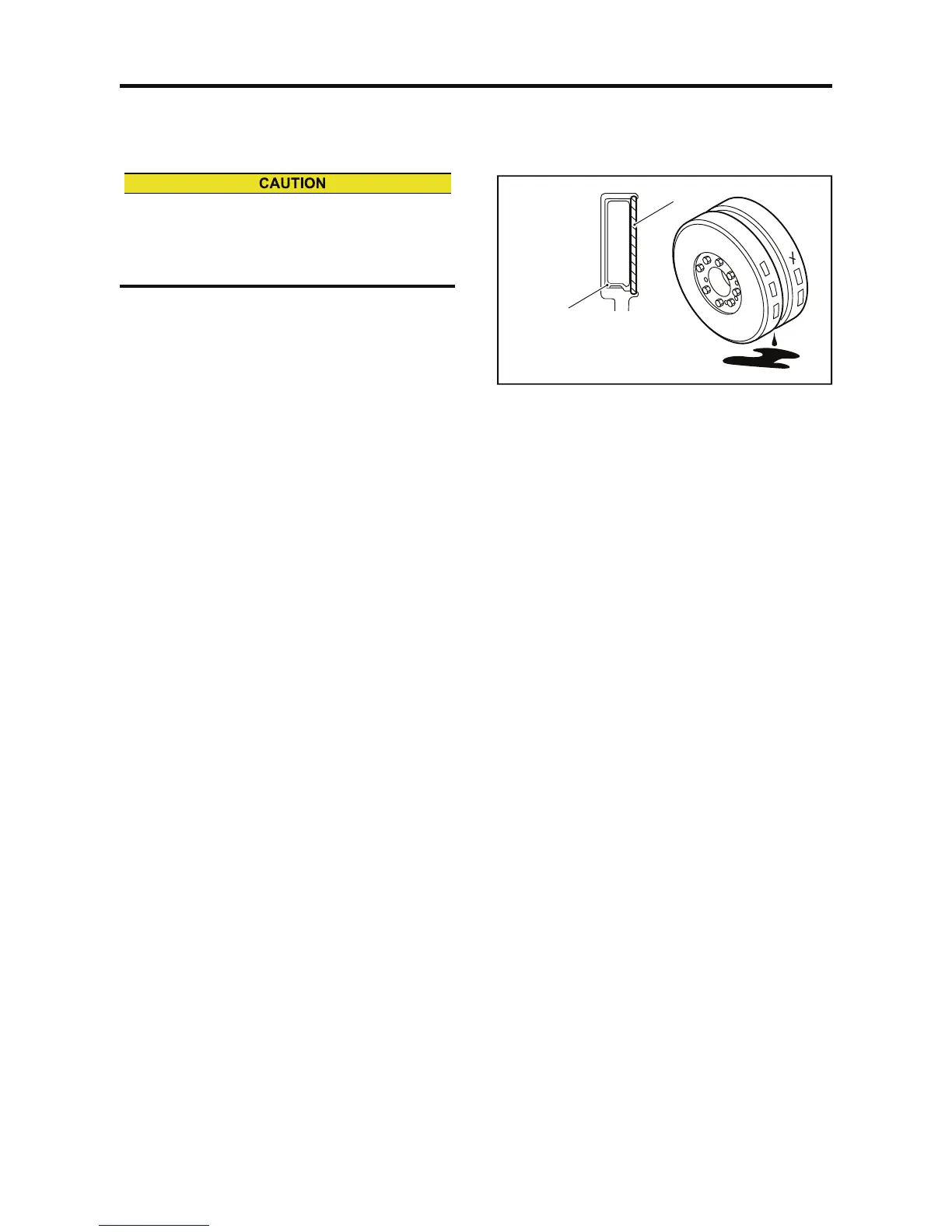

When installing a damper protective cover to the

engine, do not use a cover that encloses the damper.

Installation of a closed cover can cause damper

damage due to heat.

Cover

Silicon

oil

Loading...

Loading...