149 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

FUEL INJECTION NOZZLE

ENGLISH

FUEL SYSTEM

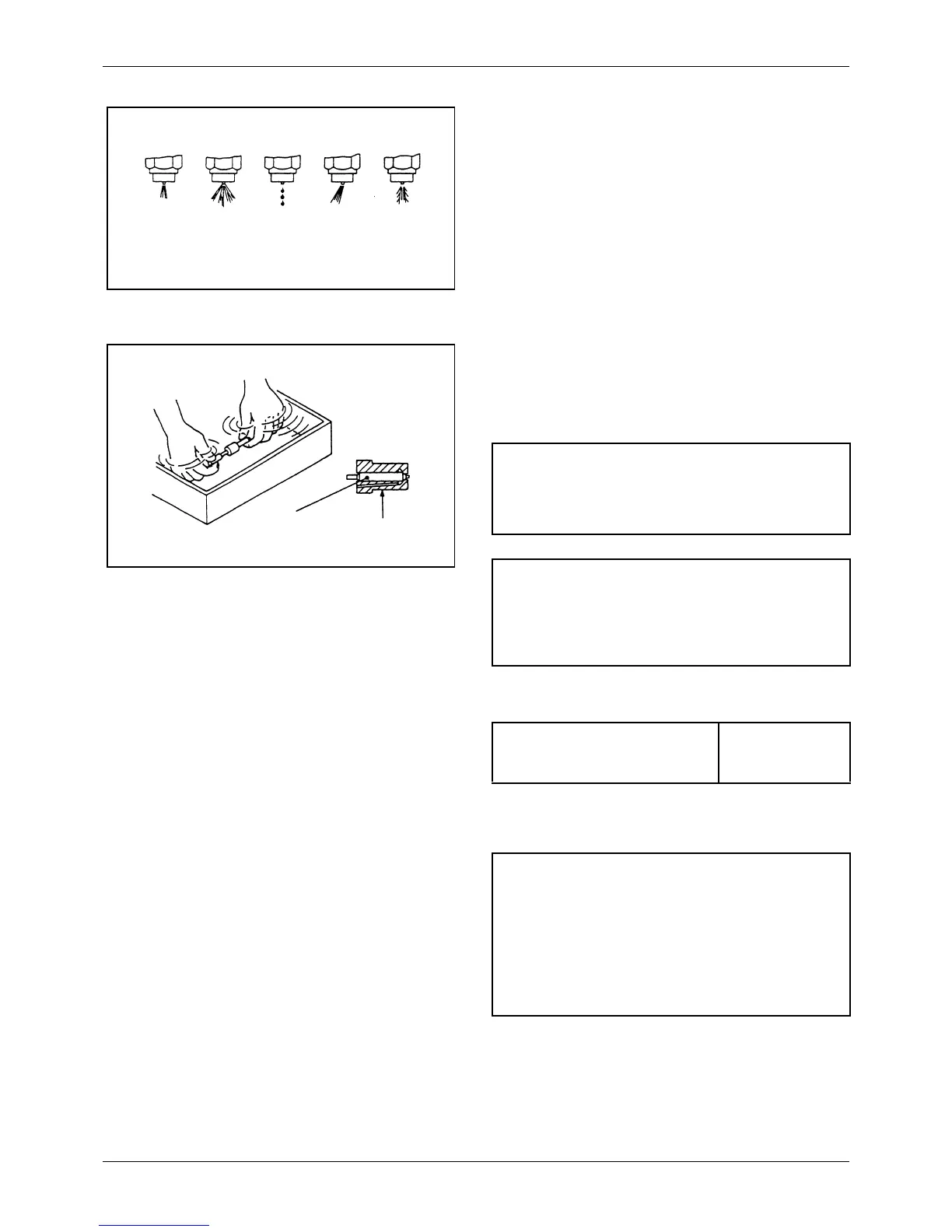

39.1.2 Orifice restriction test

1. Look at the orifice discharge pattern (shape of

discharge) when fluid begins to flow through the

injection nozzle. The discharge must be straight.

Any change is an indication of a bad nozzle.

2. Operate the tester handle at a speed of one stroke

per second to make sure the discharge is straight.

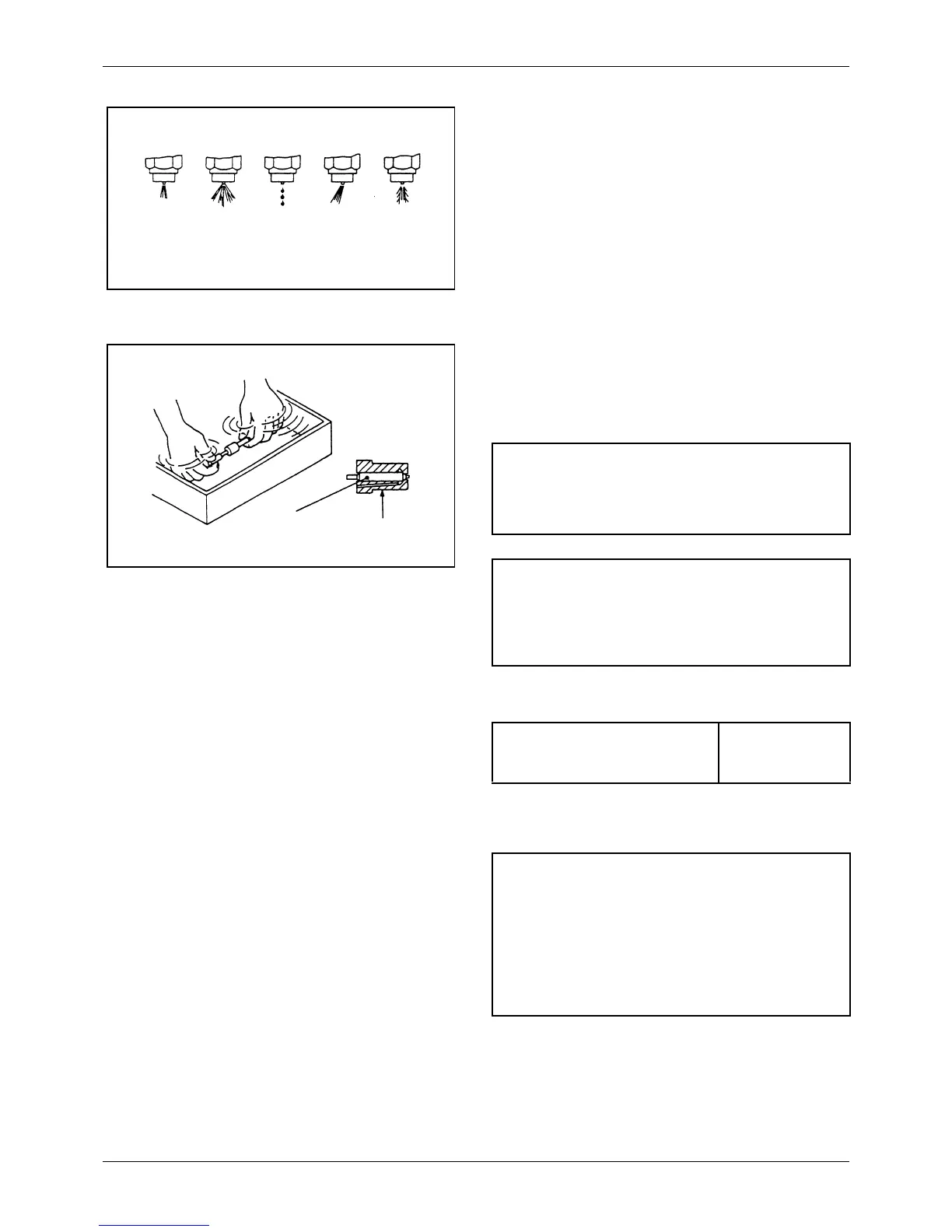

39.1.3 Nozzle tip washing and replacement

1. Loosen the retaining nut and remove the tip from

the injection nozzle. Wash the needle valve and

body in clean diesel fuel. After washing, put the

needle valve in the body in clean diesel fuel.

2. After cleaning the tip, install it in the nozzle and

tighten the retaining nut to the specified torque.

3. If the injection nozzle is still bad after the tip has

been washed, replace the tip.

Figure 217 Orifice restriction test

Good nozzle

Discharge pattern for orifice with a

restriction (recondition or replace)

Figure 218 Washing nozzle tip

Needle valve

Body

CAUTION

Do not hit the tip when removing it from the injection

nozzle.

NOTE

Keep the need valves with their respective bodies.

Do not use needle valves or bodies with other bodies

or needle valves.

Tightening torque

3.75 ± 0.25 kgf·m

(27 ± 1.8 lbf·ft)

[36.8 ± 2.5 N·m]

NOTE

a. Do not touch the sliding surface of the needle

valve.

b. When installing the new nozzle tip, remove

synthetic resin film from the tip and slide the

needle valve in the body in clean diesel fuel to

wash off inhibitor completely.

Loading...

Loading...