CSD Series Variable Frequency AC Drive

MOTORTRONICS

- 9 -

• NEVER CONNECT THE INPUT POWER WIRING TO DRIVE OUTPUT

TERMINALS T1, T2, T3. IF YOU DO, THE UNIT WILL BE DAMAGED.

• DO NOT touch any circuit components while AC power is on or

immediately after the main AC power is disconnected from the

unit. You MUST wait for the LED on the control board to

extinguish.

• DO NOT make any interconnection to the circuit before unit is

disconnected from the AC power line and the power LED on the

unit is extinguished. Failure to adhere to this warning could

result in serious or lethal injury.

• This unit is only intended for use in pollution degree 2 macro-

environment or equivalent.

• Never use a MEGGER to check the motor wires while the drive is

connected. The semiconductor output module will be destroyed by the

high transient voltage.

• If the source feeding the drive is greater than 500 KVA you should

install a three-phase, AC input line reactor to prevent possible damage

to the input rectifier bridge (3% impedance, minimum).

• If the input voltage imbalance is greater than 2%, you should also

apply an AC input line reactor (3% impedance, minimum).

• If you are using a single-phase input supply, be sure to connect the

incoming power to terminals L1 and L2 of the drive.

• Make sure there are no power factor correction capacitors connected

directly to the input or on the output leads of the drive.

• To comply with NEC requirements for branch circuit protection you

may need an externally fused disconnect.

• Recommended values for input wiring are also given in Table 3 A. For

230 V units be sure to use wire rated for 300 volts; for 460 V.

• Always use UL/CSA approved wire and listed field wiring lug kits or

listed ring terminals.

• Physically separate power and control wiring. If they must cross, do

so at 90 degree angles.

• Never install Start/Stop Magnetic Contactor (MC) between drive output

terminals and motor. The transient de-energizing surge of the magnetic

contactor will destroy the unit or cause the drive to trip.

• Never use a Start/Stop Magnetic Contactor (MC) on the line side of the

drive to Start/Stop the drive.

• Use shielded cable for all control wiring connections to the TM2 terminal

block. Ground the shield at the other end of the cable (not to the

drive).

• Use copper conductors only, size field wiring based on 75° C wire

only.

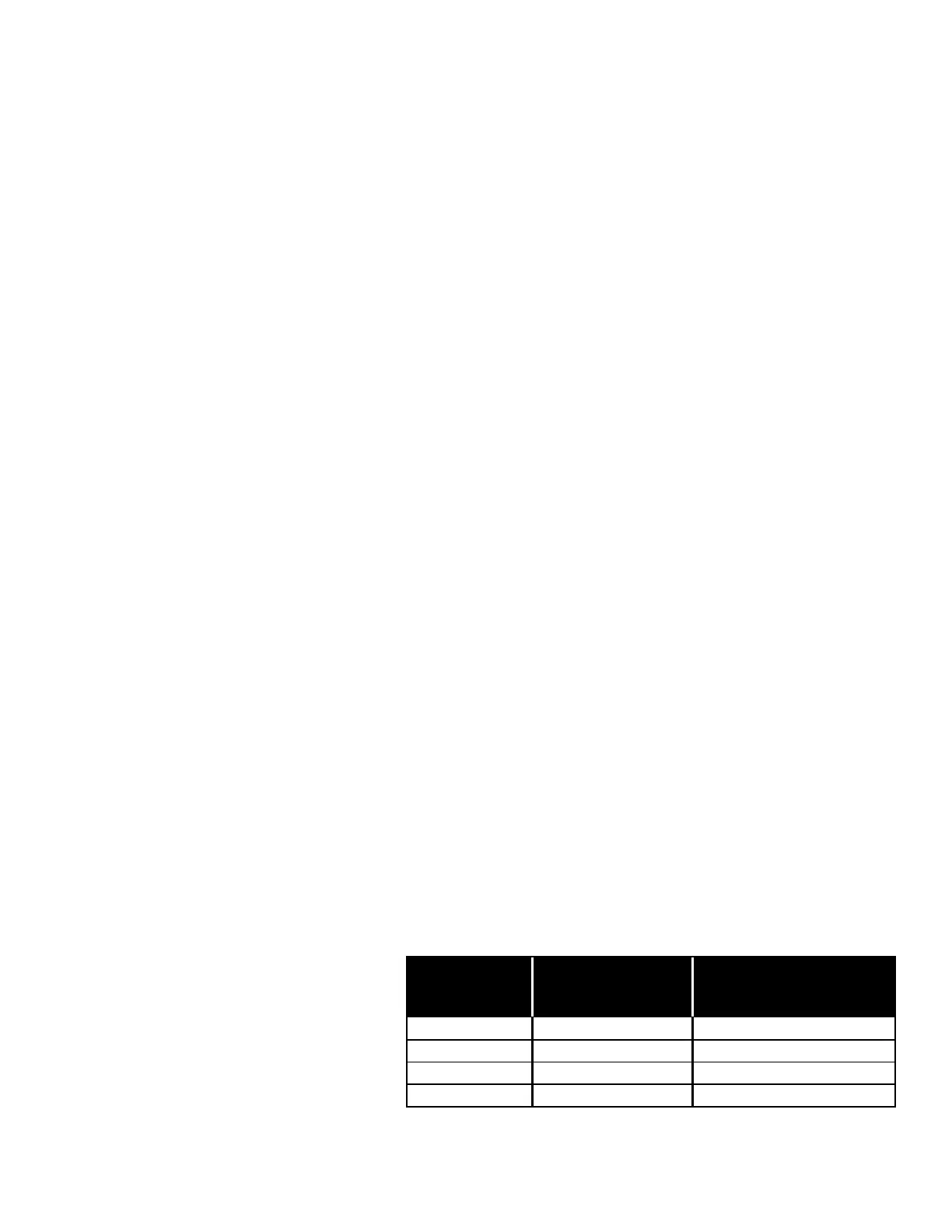

• Follow the Table 3 B for suitable supply circuits on specific drives.

(Information based on UL 508 table 47.2, February 23, 1993.)

Table 3 B - Suitable Supply Circuits

Model Max Voltage

Max Supply Short

Circuit Rating

(Symmetrical Amperes)

CSD-2P5 to CSD-201 230V 1000

CSD-202 to 230 230V 5000

CSD-401 460V 1000

CSD-402 to 430 460V 5000

Loading...

Loading...