Building

Instructions

Pleass

read these inl.uctlons

thoroughly

b€fore Startlng

work.

Compare

the

individual comoonents

with

the Pans List and

the

plan;

this

will

avoid

errors

in building,

and will speed

assembly.

It is best

to

keep to the

tollowing sequence

when building

the

'Alpina':

a Construction

ol tailplane

and

rudder'

a

Fitting of tail

components

to the luselage.

a

Installation of wing

joiner

unit

in the tuselage.

a Fitting

the

plywood parts

nto lhe

tuselage

a Capony

and latch.

a

Finishing the

wings.

a Covering

and

-

if

desjred

-

painting

Installation

of radio, and

linal adjustments.

The following

adhesives should

be used:

Foam

-

wood: white

glue,

s-minute epoxy,

Copydex,

and any other

glues

which

do not atlack

loam. Do

not

use

solvent based

glues;ifin

doubt,

try

the

adhesive

on a

piece

ol scrap

foam

Wood

-

wood:

white

glue,

instantglue

(Cyano'acryiate),

Uhu'hart' 5-minute

epoxy,

and olher

wooo

glues.

GRP

-

wood:

slow-setting

epoxy, s-minute

epoxy.

--eparatory

wolk on the

wlngs

-;e

lirst

task is to bond

the steel blades

22 and

the locating

pins

29 into the

wing

roots. lt is

imporlant to use a

high

quality,

slow-setting

epoxy

here On

no

accounl

use s-minute

glue,

such

as Devcon or

similarl

Slide

the steel

blades

into the

wings and check

thal no

more lhan 90

m m

proiecls

lrom

the root. De'grease

the blades

Now stand

the wing

panels

on

theirtips,

as nearly

vertical as

possible,

and

pourresin

intotheslots

Makesure

theglue

coats

allthe surfacesinside

by stirring

itwith a length of

wire lnsortthe

blades, check

the

proiecting length again,

and fillthe slots

with resin

until the

surfaces

are

flush. Glue

the locating

pins

29 in

place

in the same

way-the

plns

should

proiect

13

m.m. Leave lhe

wings standing

vertical

overnight

for the

resrn Io cure.

Tallolane

and

rudder

To complete

the

tailplane

panels

1 il is

only

necessary

to fit lhe tips 2. Glue

them in

place

as

per plan,

and

sand to shape.

The veneer covering

is

only

1

m.m.

thick

(to

save

weight), so take

care not to sand

through it

Glue

thetopand bottom

blocks

(4

and

5)to the rudder 3.

When

gluing

block 5

in

place,

be sure

lo tit il

far

enough

forwards

to

accommodate

the

slope

ol the

leading edge.

Sand

the blocks tlush

with the leading edge ol

the rudder'

Glue

skip 6

to the leading edge

ol the

rudder. Let all the

glued

ioints

dry

thoroughly,

then sand

the two blocks and

svip 6 to

tinal

shape,

takang care

gain

not tosand

through the

veneer. Sand an angleol

aboul

l5oeither

sideol

-{fie

centre

line

olstrrp

6,lo

allowthe

rudderto

pivot

(see planJ.

Todolhis

mark

the centre

line with a

felt-tip

pen

before

sanding the bevels

Finish

with a razor-

plane,

set

very line, to ensure

sharp corners

Fuselage

The

tailplane and

rudder can

now be attached

tothe luselage.

Thefirstjob

here

is to

fitthe all-flying

tailplane

bellcrank

7 into thelin. Take specialcare

overthis,

as

the

model's handling

in llight depends

on this assembly

operating

freely and

precisely

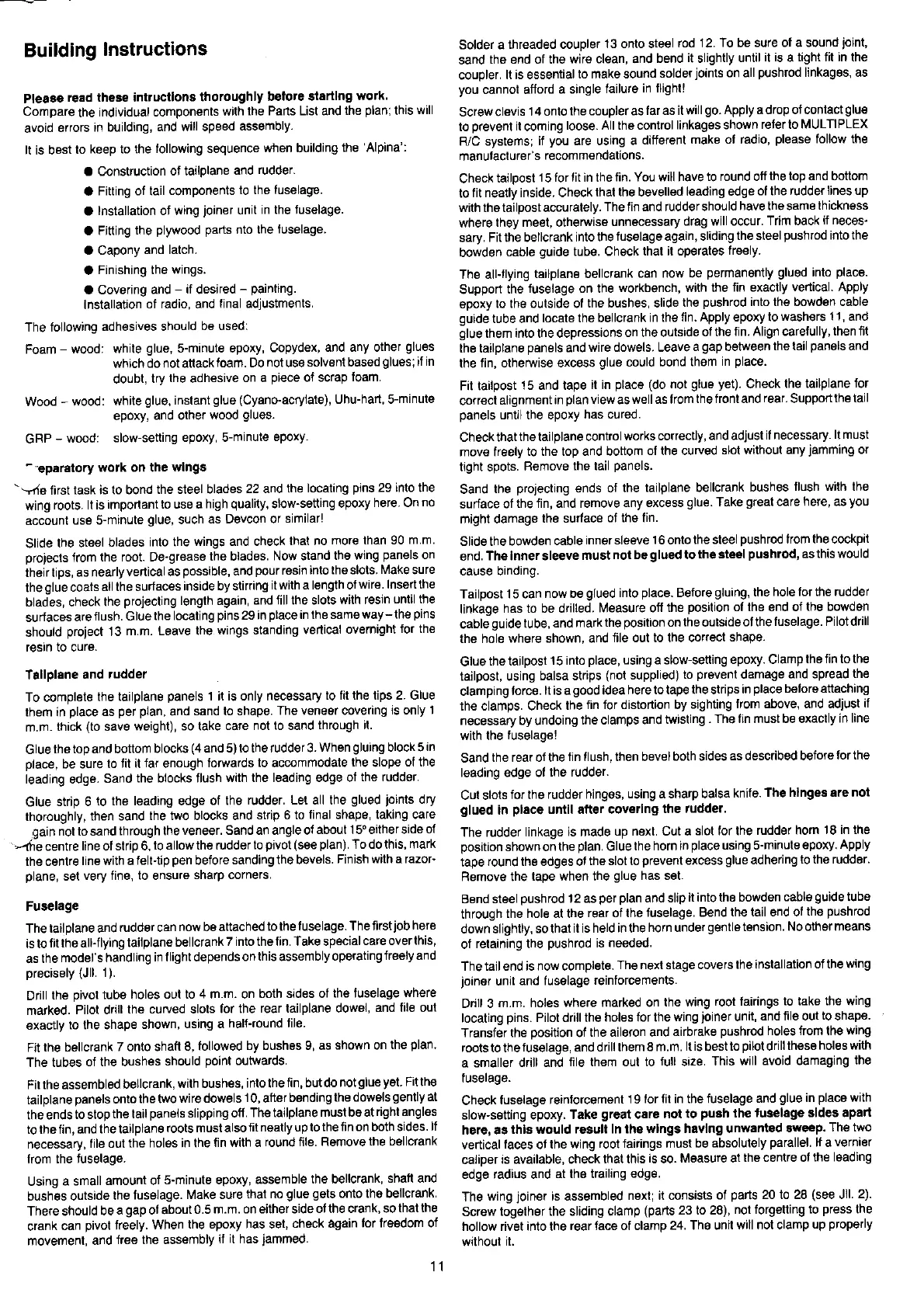

{Jll.

1).

Drill

the

pivot

tube holes

out to 4 m.m. on

both sides ol

the luselage

where

marked.

Pilot drill

the cutued slots

for the

rear tailplane dowel,

and fil6 out

exactly

to the shape

shown,

using a

half'round tile.

Fit

the bellcrank

7 onto shaft 8,

lollowed

by bushes 9, as

shown on

the

plan.

The tubes

ol the bushes

should

point

outwards

Fitthe assembled

bellcrank,

with bushes,

intothelin,

butdonotglueyet

Fitlhe

tailolane Danels

onto

the two

wire dowels

10,

after

bending

the dowels

genlly

at

the ends

to stop

the tail

panels

slipping otf.

Thetailplane

must be at

right angles

to the lin, and

the tailplan€

roots must alsofit

neatly up tothefin

on both sides.

lf

necessary,

lile out

the holes in the

fin with a

round file Remove

the bellcrank

from

the fuselage.

Using

a small

amount of

5-minute epoxy,

assemble

the bellcrank'

shall and

bushes outside

lhe

fuselage.

lvlake sure

that no

glue gets

onto the bellcrank

There should

bea

gap

ot about0.5

m.m on either side

ol the crank' so

that the

crank

can

pivot

treely.

When

the epoxy has set,

check again

tor lrssdom of

movemenl,

and

free the assembly

if it has

iammed

Solder a

threaded coupler

13 onto steel

rod 12.

To

be

sure of a sound

joint'

sand

the end of the

wire clean, and

bend

it

slightly

until

il is

a

tight fit in the

coupler.

lt is essentialto

make sound

solderjoints

on allpushrod

linkages, as

you

cannot atford

a single

lailure

in flight!

Screw clevis

14 onto

the coupler as

far as it willgo.

Apply a drop of contact

glue

to

prevent

it

coming

loose. Allthe control

linkages shown

refer to MULTIPLEX

FyC systems;

if

you

are using a

ditfelent

make of radio,

please

follow the

manufaclurer's

recommendations.

Check

tailpost

15 forlit in thefin.

You will have

to round off

the top and bottom

to

fit neatly inside. Check

that the bevelled

leading edge

of the

rudder lines up

with thetailpost accurately.

The lin and ruddershould

have the same

thickness

where

they meet, otheMise

unnecessary

drag willoccur'

Trim back

if neces'

sary.

Fitthe bellcrank

intothe

fuselageagain, sliding

thesteelpushrod

intothe

bowden

cable

guide

tube. Check

that it operates

lreely

The all-tlying

tailplane bellcrank

can now be

permanently glued

into

place.

Support

the

fuselage on the

workbench, with the

fin exactly

vertical. Apply

epoxy

to the outside of

the bushes, slide

the

pushrod

into the bowden cable

guide

tube and

locate the bellcrank

in the

fin. Apply epoxy to

washers 11, and

glue

them into the depressions

on the outside

ofthe

fin. Align carefully,

then fit

the tailplane

panels

and

wire dowels. Leave

a

gap

between

thetailpanels and

the

fin,

otherwise

excess

glue

could bond

them

in

place.

Fit tailpost

15 and tape

it in

place (do

not

glue

yet).

Check

the tailplane

for

correct

alignment

in

plan

viewas

wellas lrom

the front and

rear.

Supportthe

tail

panels

until the epoxy

has cured.

Checkthat

the tailplane controlworks

correctly,

and adjust

if necessary.

lt must

move lreely

to the top and bottom

of the curved

slot without any

jamming

or

tight spots.

Remove

the tail

panels.

Sand

the

projecting

ends of the

tailplane bellcrank

bushes

flush with the

surface

of

the fin, and remove

any excess

glue.

Take

great

care hele, as

you

might damage

the surlace

of the fin.

Slide the bowden

cable

innersleeve

16

onto

the steel

pushrod

hom the cockpit

end.

The Inner sleeve

must

not be

glued

tothe

steel

pushrod,

asthis would

cause binding.

Tailpost 15 can

now be

gtued

into

place.

Before

gluing,

the

hole for the rudder

linkage

has to be drilled.

l\,leasure otf

the

position

of the end of

the

bowden

cable

guide

tube,

and mark

the

position

on

the

outside

of the

fuselage Pilotdrill

the hole

where shown, and

lile out to the correct

shape.

Glue

thetailpost

15 into

place,

using a slow-sening

epoxy. Clamp

the lin to the

tailpost, using

balsa strips

(not

supplied)

to

prevent

damage

and spread

the

damping

force.

lt is

agood

idea

heretotape the strips

in

place

belore attaching

the clamps. Check

the

fin for distortion by

sighting

from above, and adiust

il

necessary by undoing

the clamps and

twisting

. The fin must be exactly

in line

with the

fuselage!

Sand

the rear ofthe

fin llush, then bevelboth

sides

as described beforeforthe

leading edge ol

the rudder.

Cul slots

for lhe

rudder hinges,

using a sharp balsa

knife.

The hlnges are nol

glued

in

place

untll afler coverlng

the

rudde..

The rudder

linkage is made

up next. Cut a

slot lor lhe

rudder horn

18 in the

position

shownonthe

plan.

Gluethe

horn in

placeusing

s-minuteepoxy.

Apply

tape

round the edges ot

theslotto

prevent

excess

glue

adhering

to the rudder.

Remove the

tape when the

glue

has set.

Bend steel

pushrod

12 as

per plan

and slip

it into the bowden

cable

guide

tube

through

the hole at the

rear of the

fuselage. Bend

the tail end ol

the

pushrod

down slightly,

sothatit

is held inthe

horn under

gentle

tension

Noothermeans

of

retaining the

pushrod

is

needed.

Thetailend is nowcomplete.

The next stage covers

the installation

ol the wing

ioinsr

unit

and fuselage

reinforcements.

Drill 3

m.m. holes

where marked on

the wing

root lairings

to take the wing

locating

pins.

Pilot drillthe

holes forthe

wing

ioiner

unit,

and lile out

to

shape.

Transfer the

position

ol

the aileron and

airbrake

pushrod holes from the

wing

roots to the

fuselage, and drilllhem

8 m.m.

lt is

best

to

pilot

drillthese

holes

with

a smaller

drill and

file them out to

full

size.

This

will avoid damaging

the

tuselage.

Check

fuselage r€inforcement

19

for fit in the fuselage

and

glue

in

place

with

slow-setting

epoxy.

Take

great

care

not to

push

the tuselage

sldes apart

here, as

thls would

result In lhe wings

havlng unwanted

sweep.

The two

vertical

faces

of

the wing

root fairings must be

absolulely

parallel

l{ a

vernier

caliper

is available, check

that this

is

so.

Moasure at

the centre ol

the leading

edge radius and

at the trailing

edge.

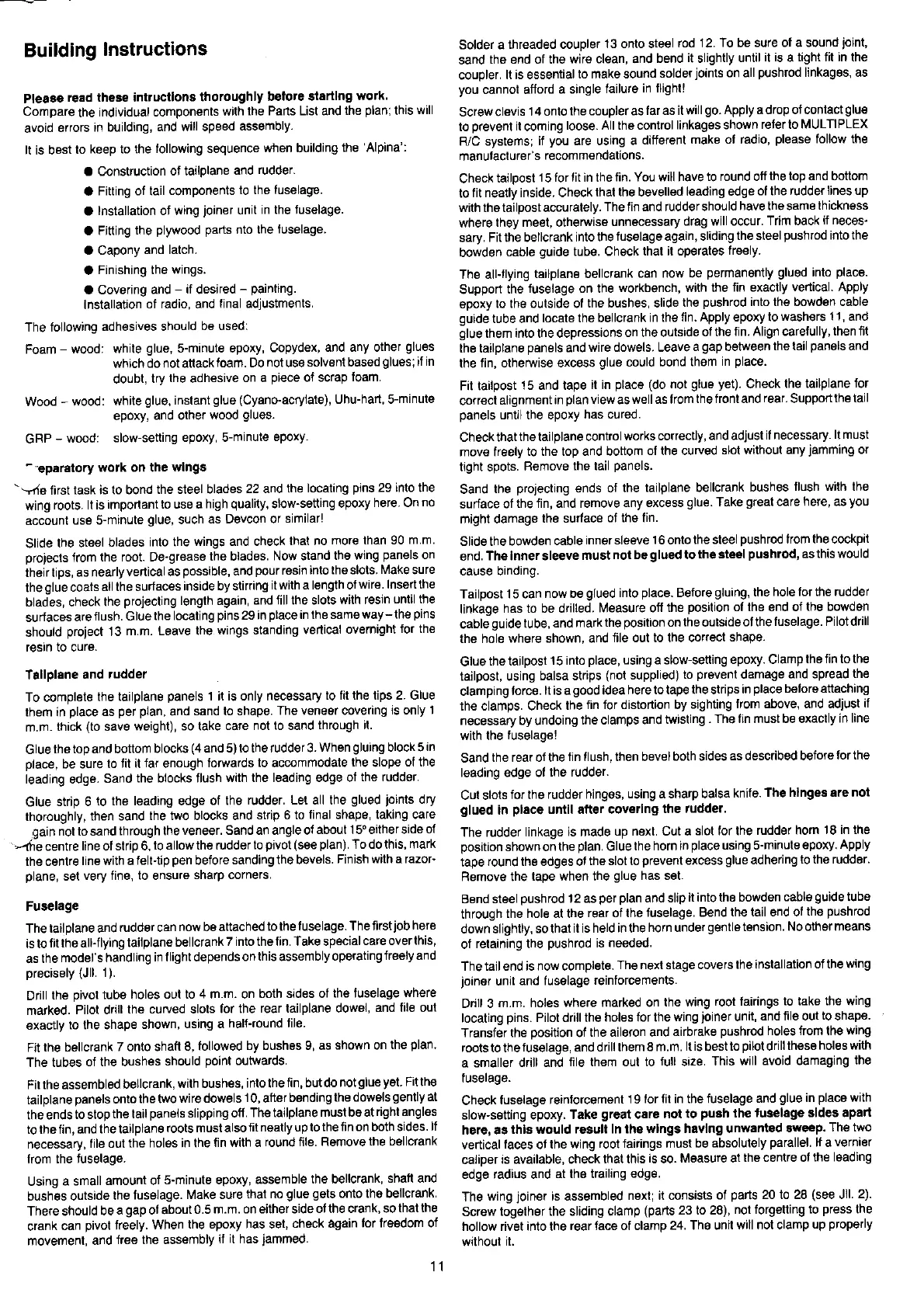

The

wing

joiner

is assembled

next; it consists

ol

parts

20 to 28

(see

Jll

2).

Screw

together the sliding clamp

(parts

23 to 28),

not forgetting

to

press

the

hollow rivet into the

rear face ol clamp

24. The unit

will not clamp

up

properly

withoul

it.

11

Loading...

Loading...