14

NETAFLEX™ 3G USER MANUAL

OPERATION AND MAINTENANCE

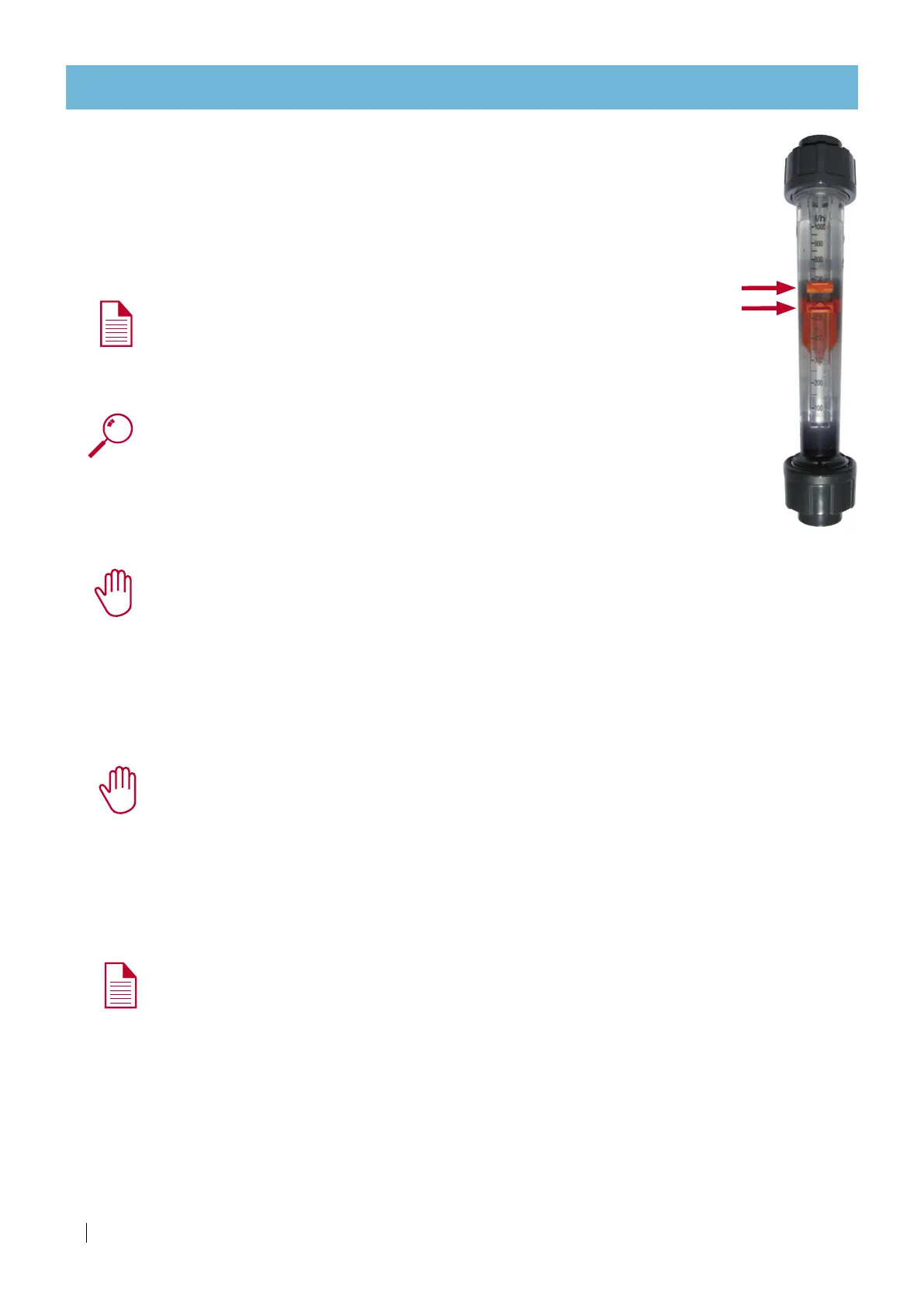

Check the NetaFlex™ 3G hydraulic conditions every 4 weeks

Check the pressure gauge and the Rotameters of the dosing channels and compare the

data to the initial settings in the controller (NMC Pro - screen 7.6). Make sure that no significant

changes occurred to the hydraulic conditions of the NetaFlex™ 3G.

When verifying the flow rate for each dosing channel,

make sure the cursors on all the Rotameters are adjusted.

NOTE

The Rotameter's sacle is calibrated by the manufacturer for measurement of the

flow rate of water (H

2O). Certain inacuracies may be observed when the flow rate

of liquids with different densities, such as fertilizers and acids, is measured.

ATTENTION

Once a month, read the measured flow rates of the dosing channels

and compare them with the flow rates defined in the controller,

to check whether any changes have occurred.

Winterization

CAUTION

When opening or closing any manual valve, always do it gradually, to prevent damage to the

system by water hammer.

If

the NetaFlex™ 3G is located in an unheated space

where the temperature might drop below 5°C (41°F), if

the system is not required for irrigation during the winter, perform the following procedure

to avoid damage

caused by freezing when the NetaFlex™ 3G is idle for the winter period:

At the beginning of winter:

CAUTION

Before removing the EC and pH sensors, make sure there is no pressure in the system.

•

Remove EC and pH sensors and store the pH sensor immersed in KCL solution (supplied with the sensor)

or in calibration buffer 4 at temperature 18-25˚C (64-77˚F). The pH sensor must never be dry

(see the EC/pH Transmitter Manual).

• Empty the NetaFlex™ 3G of water.

At the end of winter:

NOTE

It is reccomended to install new

EC and pH sensors at the begining of a new season.

• Reinstall the EC and pH sensors and calibrate them (see the EC/pH Transmitter Manual).

• Restore the pressure in the system.

Loading...

Loading...