INTRODUCTION

Torque-Standardtorquedataforhydraulics

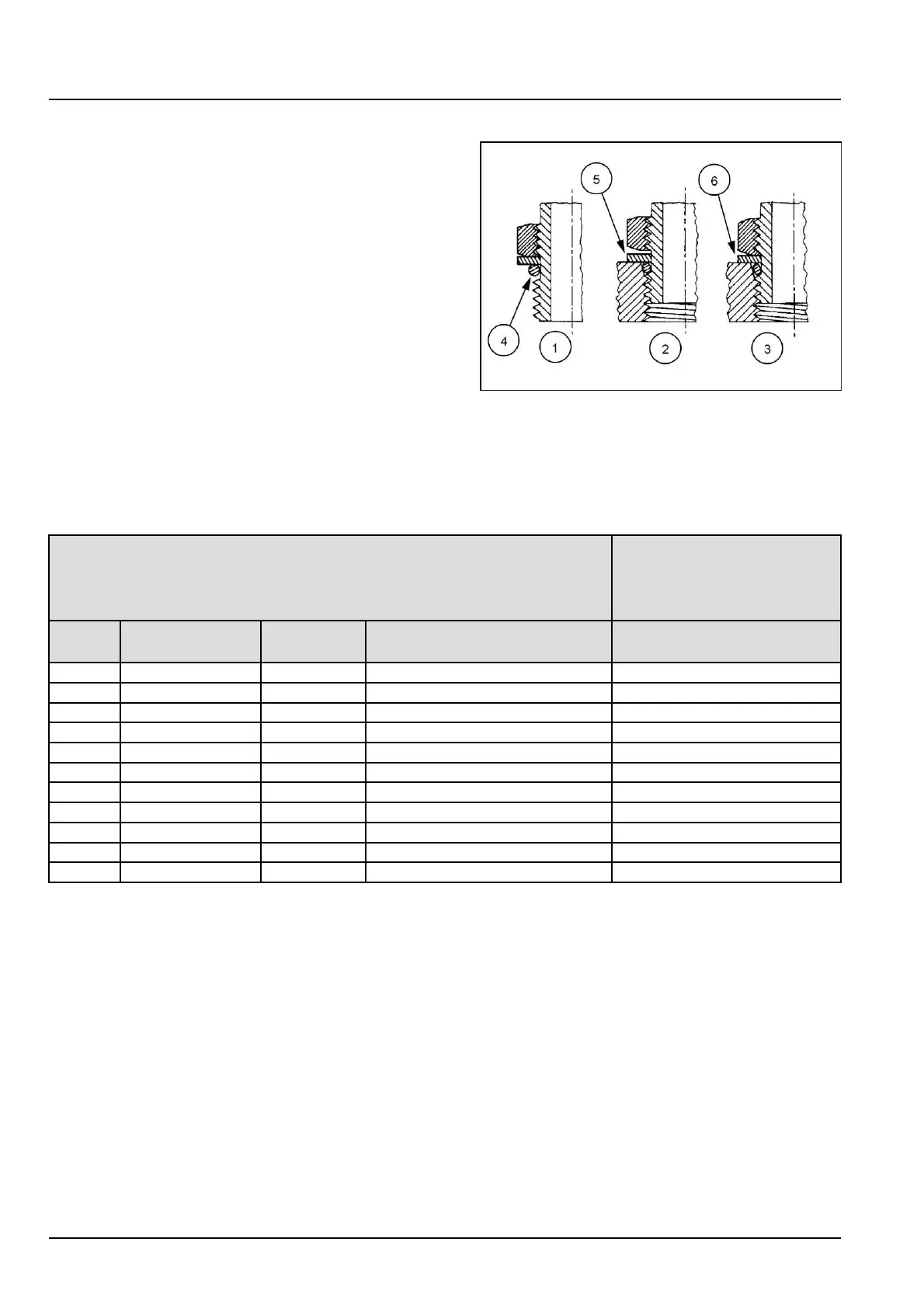

INSTALLATIONOFADJUSTABLEFITTINGS

INSTRAIGHTTHREADORINGBOSSES

1.LubricatetheO-ringbycoatingitwithalightoilor

petroleum.InstalltheO-ringinthegrooveadjacent

tothemetalbackupwasherwhichisassembledatthe

extremeendofthegroove(4).

2.InstallthettingintotheSAEstraightthreadbossuntil

themetalbackupwashercontactsthefaceoftheboss

(5).

NOTE:Donotovertightenanddistortthemetal

backupwasher.

3.Positionthettingbyturningout(counterclockwise)

uptoamaximumofoneturn.Holdingthepadofthe

ttingwithawrench,tightenthelocknutandwasher

againstthefaceoftheboss(6).

230856591

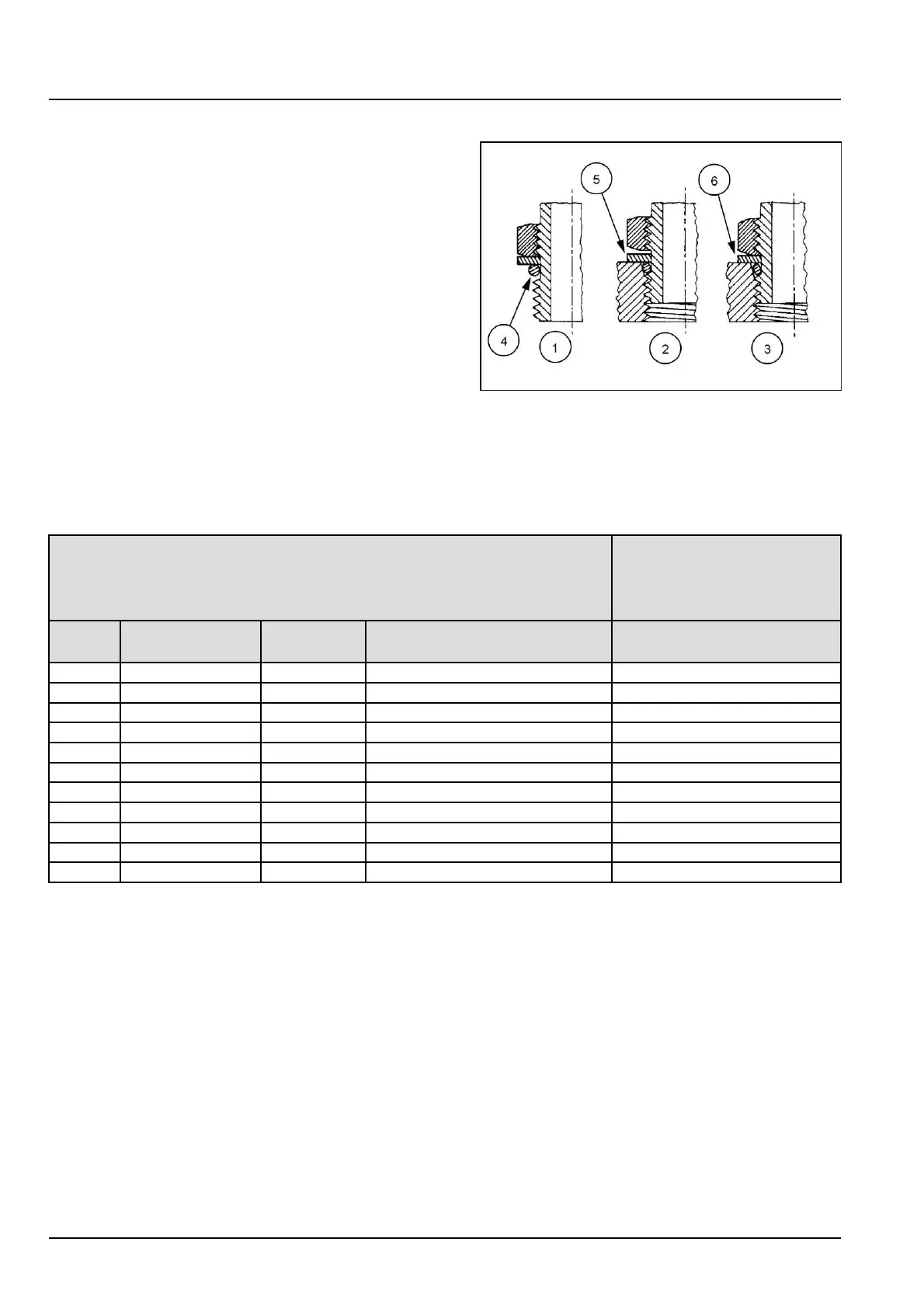

STANDARDTORQUEDATAFORHYDRAULICTUBESANDFITTINGS

TUBENUTSFOR37°FLAREDFITTINGSO-RINGBOSSPLUGS

ADJUSTABLEFITTING

LOCKNUTS,SWIVEL

JIC-37°SEATS

SIZETUBINGOD

THREAD

SIZE

TORQUETORQUE

4

6.4mm(1/4in)7/16-2012–16N·m(9–12lbft)8–14N·m(6–10lbft)

5

7.9mm(5/16in)1/2-2016–20N·m(12–15lbft)14–20N·m(10–15lbft)

6

9.5mm(3/8in)9/16-1829–33N·m(21–24lbft)20–27N·m(15–20lbft)

8

12.7mm(1/2in)3/4-1647–54N·m(35–40lbft)34–41N·m(25–30lbft)

10

15.9mm(5/8in)7/8-1472–79N·m(53–58lbft)47–54N·m(35–40lbft)

12

19.1mm(3/4in)1-1/16-12104–111N·m(77–82lbft)81–95N·m(60–70lbft)

14

22.2mm(7/8in)1-3/16-12122–136N·m(90–100lbft)95–109N·m(70–80lbft)

16

25.4mm(1in)1-5/16-12149–163N·m(110–120lbft)108–122N·m(80–90lbft)

20

31.8mm(1-1/4in)1-5/8-12190–204N·m(140–150lbft)129–158N·m(95–115lbft)

24

38.1mm(1-1/2in)1-7/8-12217–237N·m(160–175lbft)163–190N·m(120–140lbft)

32

50.8mm(2in)2-1/2-12305–325N·m(225–240lbft)339–407N·m(250–300lbft)

Thesetorquesarenotrecommendedfortubesof12.7mm(1/2in)ODandlargerwithwallthicknessof0.889mm

(0.035in)orless.Thetorqueisspeciedfor0.889mm(0.035in)walltubesoneachapplicationindividually.

Beforeinstallingandtorquing37°aredttings,cleanthefaceoftheareandthreadswithacleansolventorLoctite

cleanerandapplyhydraulicsealanttothe37°areandthethreads.

Installttingandtorquetospeciedtorque,loosenttingandretorquetospecications.

4806812829/01/2018

16

Loading...

Loading...