4-3-4 (d) WHITE BALANCE ADJUSTMENT VERIFICATION

Refer to the procedure for 9300K, section 4-3-2 (d).

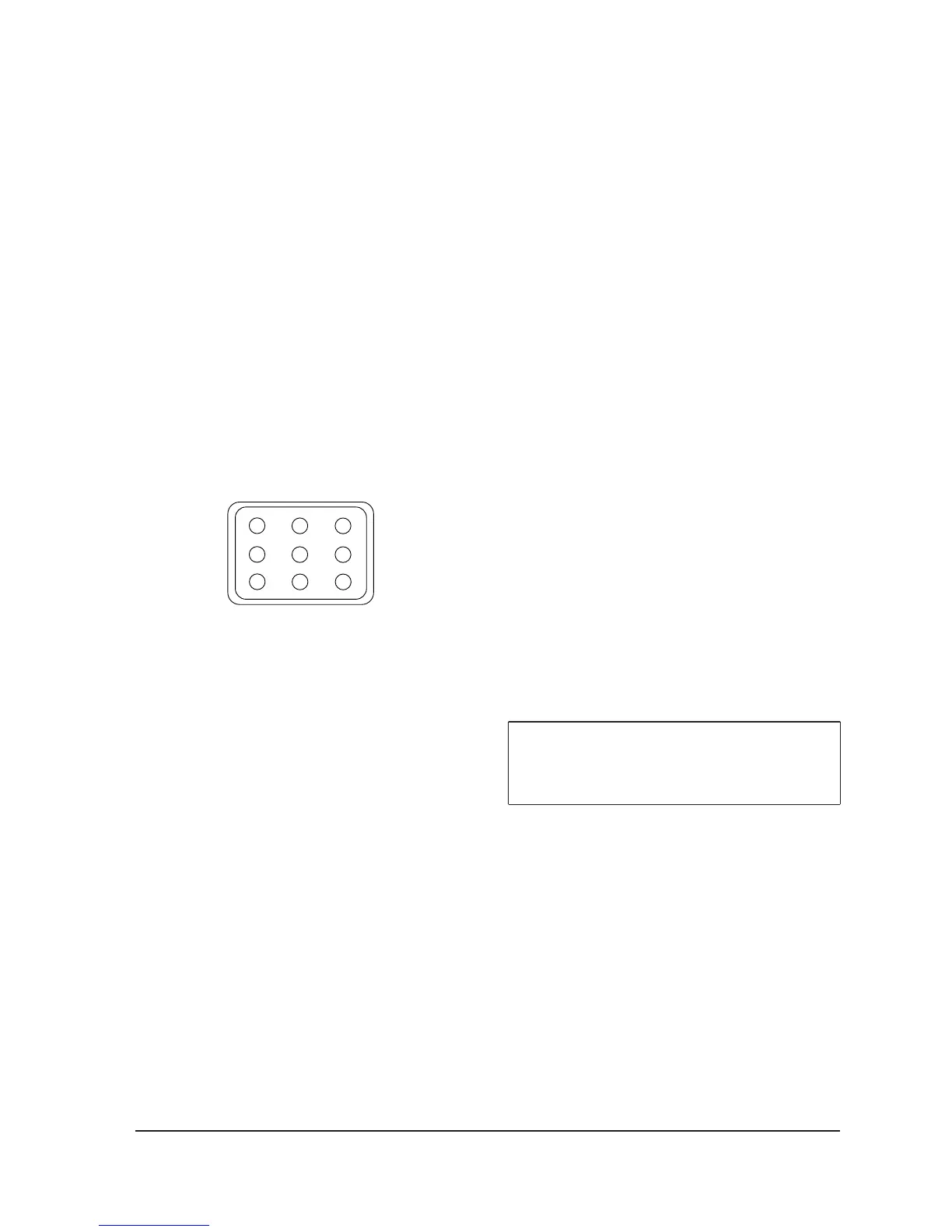

4-3-5 Luminance Uniformity Check

Luminance is considered uniform only if the ratio

of lowest to highest brightness areas on the screen

is not less than 7.5:10.

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

(1024 x 768)

Display image: White flat field

Display size: 355(H) x 266(V)/920C ~ 310(H) X 232(V)/720C

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

Measure luminance at nine points on the display

screen (see figure below).

4-3-6 Focus Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: ÒHÓ character pattern

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible.

2. Use Locktite to seal the Focus VR in position.

4-3-7 Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a

uniform field) within the display area shall not be

visible at a distance of 50 cm from the CRT

surface.

CONDITIONS

Orientation: Monitor facing east

Scanning frequency: 68 kHz/85 Hz

Display image: White flat field

Luminance: Cut off point at the center

of the display area

Note: Color purity adjustments should only be

attempted by qualified personnel.

PROCEDURE (adjusting convergence)

For trained and experienced service technicians

only.

Use the following procedure to correct minor

color purity problems:

1. Make sure the display is not affected by

external magnetic fields.

2. Very carefully break the glue seal between the

2-pole purity convergence magnets (PCM), the

band and the spacer.

3. Make sure the spacing between the PCM

assembly and the CRT stem is 29 mm ± 1 mm.

4. Display a green pattern over the entire display

area.

5. Adjust the purity magnet rings on the PCM

assembly to display a pure green pattern.

(Optimum setting: x = 0.295 ± 0.015,

y = 0.594 ± 0.015)

6. Repeat steps 4 and 5 using a red pattern and

then again, using a blue pattern.

Table 4-3. Color Purity Tolerances

(For 9300K color adjustment: x = 0.283 ± 0.02, y = 0.297 ± 0.02)

7.When you have the PCMs properly adjusted,

carefully glue them together to prevent their

movement during shipping.

4 Alignment and Adjustments

720C/920C 4-7

Red: x = 0.620 ± 0.015 y = 0.334 ± 0.015

Green: x = 0.289 ± 0.015 y = 0.595 ± 0.015

Blue: x = 0.153 ± 0.015 y = 0.072 ± 0.015

Figure 4-10 Luminance Uniformity Check Locations

Loading...

Loading...