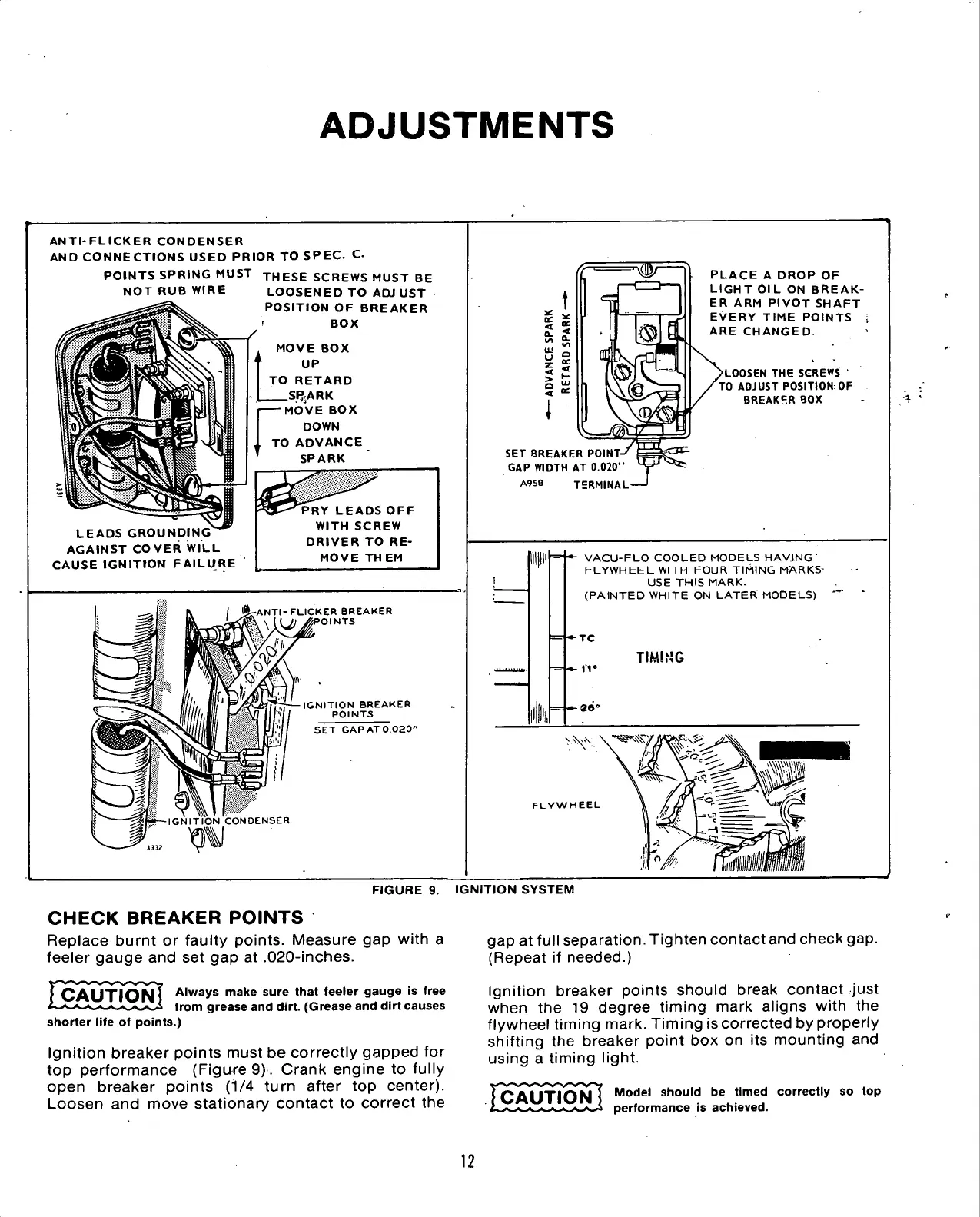

ADJUSTMENTS

ANTI-FLICKER CONDENSER

AND CONNECTIONS USED PRIOR

TO

SPEC.

C

POINTS SPRING MUST

JHESE

SCREWS MUST

BE

NOT

RUB

WIRE LOOSENED

TO ADJ UST

POSITION

OF

BREAKER

'

BOX

MOVE

BOX

UP

TO RETARD

.SPjARK

— MOVE

BOX

DOWN

TO ADVANCE

SPARK

LEADS GROUNDING

AGAINST

CO VER

WILL

CAUSE IGNITION FAILURE

PRY LEADS

OFF

WITH SCREW

DRIVER

TO RE-

MOVE THEM

ISANTI-FLICKER BREAKER

OINTS

IGNITION BREAKER

POINTS

SET GAP AT 0.020"

PLACE

A

DROP

OF

LIGHT

OIL ON

BREAK-

ER

ARM

PIVOT SHAFT

EVERY TIME POINTS

;

ARE CHANGED.

LOOSEN

THE

SCREWS

TO ADJUST POSITION

OF

BREAKF.R

BOX

SET BREAKER POINT-

GAP WIDTH

AT

0.020"

A958 TERMINAL

VACU-FLO COOLED MODELS HAVING

FLYWHEEL WITH FOUR TIMING MARKS-

USE THIS MARK.

(PAINTED WHITE

ON

LATER MODELS)

TC

TIMING

FLYWHEEL

FIGURE

9.

IGNITION SYSTEM

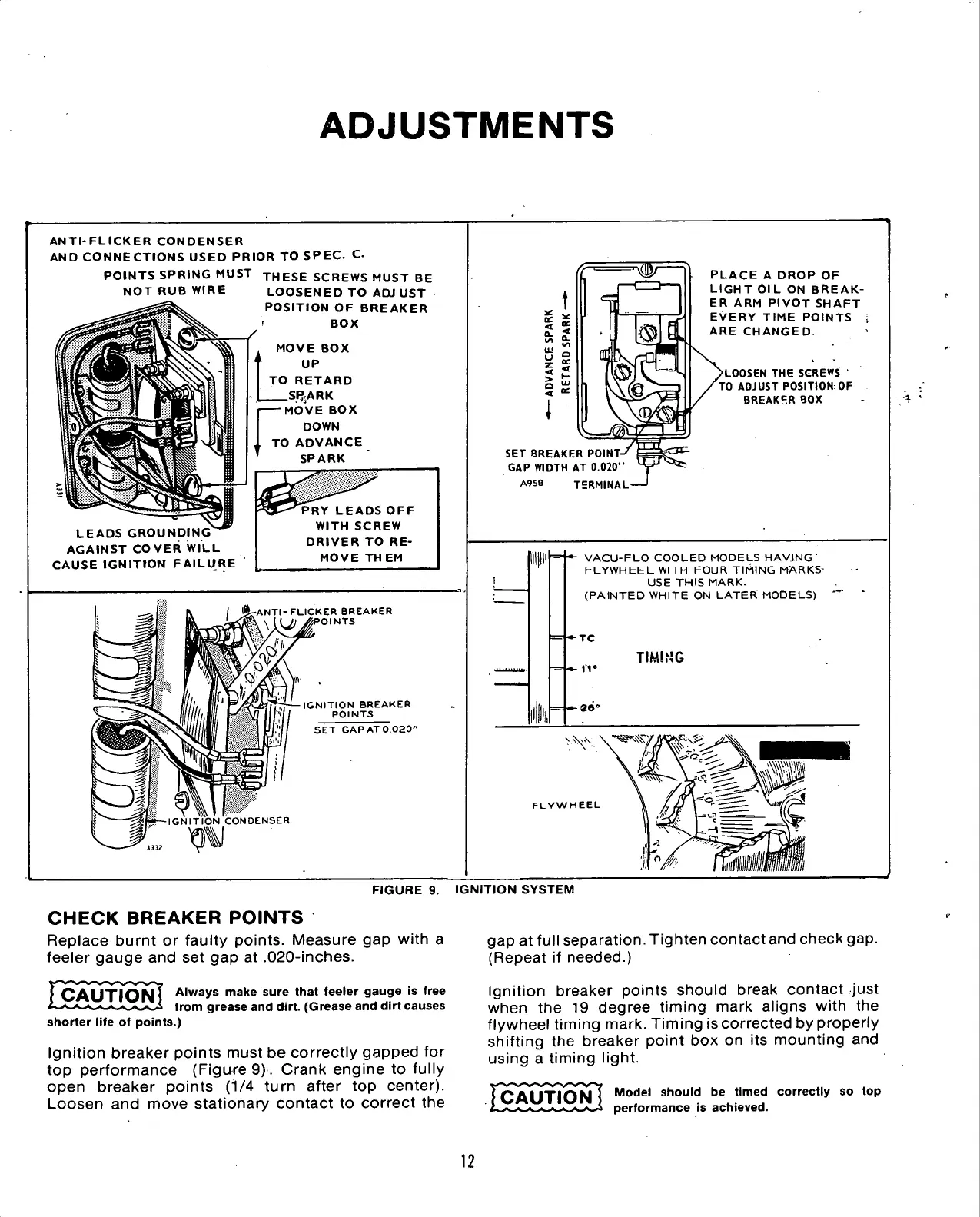

CHECK

BREAKER

POINTS

Replace burnt

or

faulty points. Measure

gap

with

a

feeler gauge

and set gap at

.020-inches.

|Q^yy|Q(iJ7 Always make sure that feeler gauge

is

free

i^x-x^^^^-^^i

from

gre

i grease

and

dirt. (Grease

and

dirt causes

shorter life

of

points.)

Ignition breaker points must

be

correctly gapped

for

top performance (Figure

9)'.

Crank engine

to

fully

open breaker points

(i/4

turn after

top

center).

Loosen

and

move stationary contact

to

correct

the

gap

at

full separation. Tighten contact and check

gap.

(Repeat

if

needed.)

Ignition breaker points should break contact just

when

the 19

degree timing mark aligns with

the

flywheel timing mark. Timing

is

corrected

by

properly

shifting

the

breaker point

box on its

mounting

and

using

a

timing light.

^Q^yyjoj^l^

Model should

be

timed correctly

so top

performance

is

achieved.

12

Loading...

Loading...