15

Battery Cables

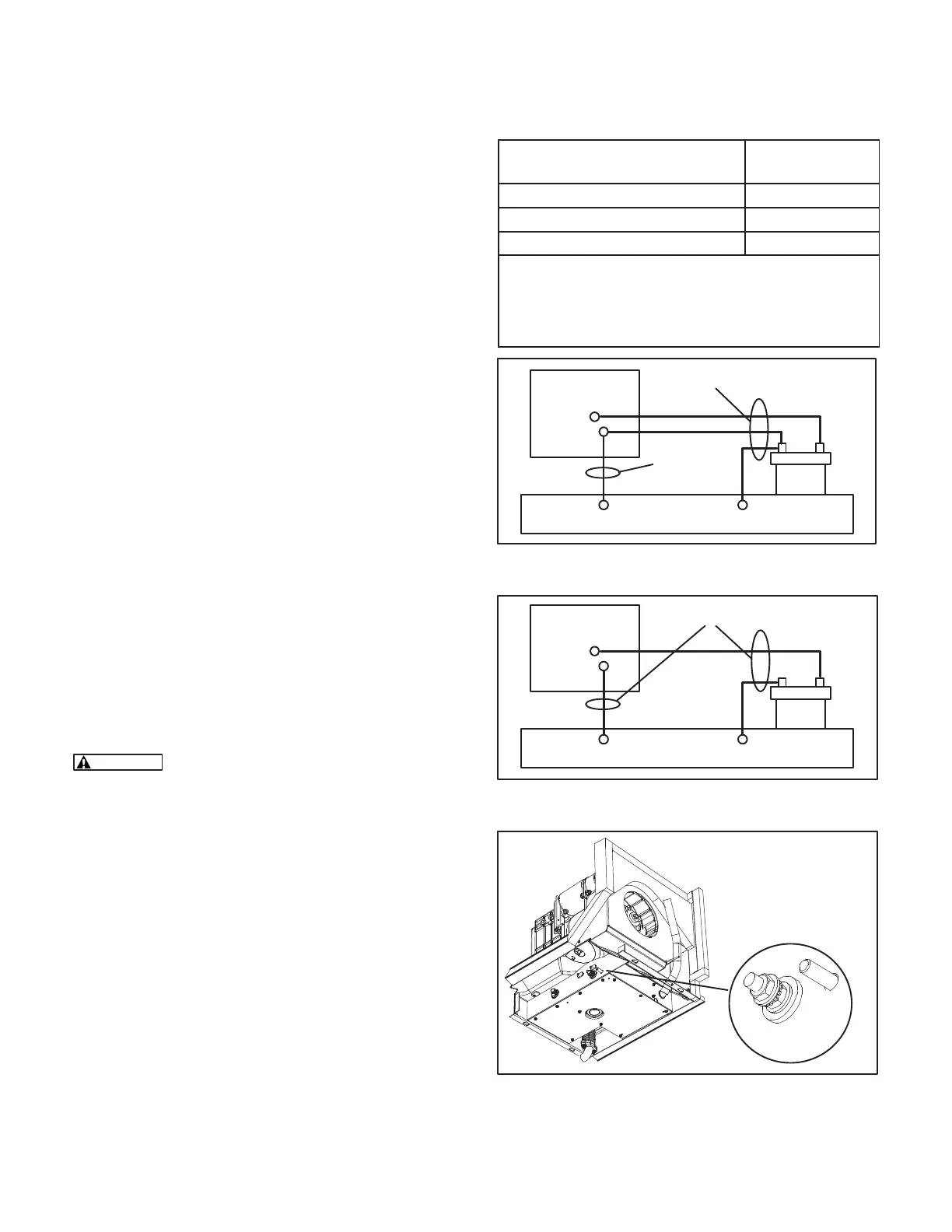

Size battery cables according to Table 2. The cur-

rent path between the genset and the negative (–)

battery terminal must also be able to carry full crank-

ing current without causing excessive voltage drop.

It is highly recommended that a full-length cable be

used to connect the genset to the negative (–) bat-

tery terminal (Figure 15). Note also that codes may

require bonding conductors from the genset and the

battery to the vehicle frame.

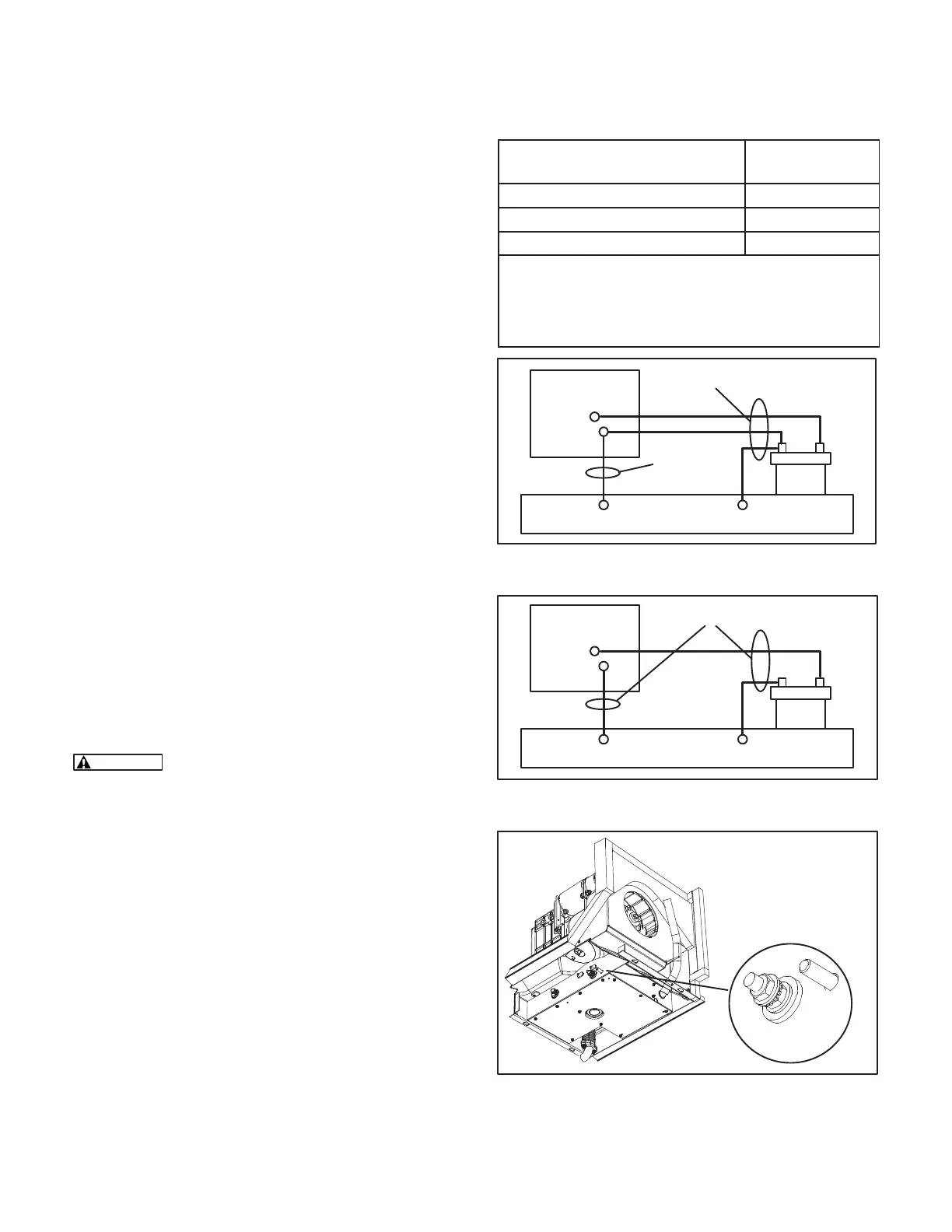

If a full-length negative (–) cable is not run from the

battery (Figure 16), all vehicle frame members in

the path of battery cranking currents must have sub-

stantial crossections. The electrical resistance of

riveted or bolted frame joints must also be carefully

considered, especially if the joints will be exposed to

corrosive conditions. A cable must be used to con-

nect the frame to the designated negative (–) termi-

nal on the genset (Figure 16). The cable must be

sized according to Table 2. The genset mounting

bolts are not considered adequate means for

bonding the genset to the vehicle frame, either

for the purpose of carrying cranking currents or

for complying with requirements for genset/

system grounding.

Route battery cables away from fuel lines and hot

engine exhaust components. Battery cables should

be accessible for inspection and replacement,

protected from damage and secured to prevent

chafing due to vibration.

WARNING

Routing battery cables with fuel

lines can lead to fire and severe personal injury

or death. Keep battery cables away from fuel

lines.

Terminate the battery cables with appropriately

sized eyelet connectors and connect them to the

genset as shown in Figure 17.

TABLE 2. BATTERY CABLE SIZES FOR

TEMPERA

TURES DOWN TO –20° F (–29°C)

TOTAL CABLE LENGTH*

FEET (METERS)

CABLE SIZE

A

WG

0 to 10 (0 to 3) 2**

11 to 15 (3 to 4.5) 0

16 to 20 (4.5 to 6) 000

* – Add the negative battery cable lengths with the positive

battery cable lengths for the total.

** – A total length of up to 20 feet (6 meters) may be used

in warmer climates or when battery capacity totals at least

1000 CCA (Cold Cranking Amps).

GENSET

BAT

–+

–

+

SIZE PER TABLE 2

#8 AWG

MINIMUM

VEHICLE FRAME

FIGURE 15. FULL-LENGTH CABLE FROM

BATTERY NEGATIVE (–) TERMINAL

GENSET

BAT

–+

–

VEHICLE FRAME

+

SIZE PER TABLE 2

FIGURE 16. VEHICLE FRAME AS PATH FROM

BATTERY NEGATIVE (–) TERMINAL

+

–

FIGURE 17. BATTERY CABLE CONNECTIONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...