ADJUSTMENT PROCEDURE-1

IDLING CURRENT ADJUSTMENT

HT-R640

[Procedure]

<Note> No load and No signal

Refer to <Fig-1> in " ADJUSTMENT PROCEDURES-2 " for the adjustment points and the test points.

1. Before idling adjustment, turn the trimming resistors to counter clockwise.

2. Connect the dc voltmeter to test points,

using two 100 ohm resistors between the poles of the jig terminal and the dc voltmeter terminals.

6. Wait for 4 - 6 minutes. (Heat running)

7. Re-adjust the trimming resistors as the following procedure.

Adjustment point

(Trimming resistor)

R6040

R6041

R6042

R6043

R6044

Adjustment value

2.5 mV

2.5 mV

2.5 mV

1.5 mV

1.5 mV

Measuring point

(Test point)

P6080

P6081

P6082

P6083

P6084

Adjustment point

R6041, R6042

and R6040

R6043, R6044

Adjustment value

9 mV

Leave it as it is

11 mV

6 mV

Leave it as it is

8 mV

Measured value

In case below 9 mV

In case 9 - 11 mV

In case over 11 mV

In case below 6 mV

In case 6 - 8 mV

In case over 8 mV

3. Connect the ac power cord to wall outlet.

4. Press the STANDBY/ON button to turn the power on.

5. Adjust the trimming resistors as the following procedure immediately after power on.

Channel

Center

Front Left

Front Right

Surround Left

Surround Right

Channel

Front Left, Right

and Center

Surround Left

Surround Right

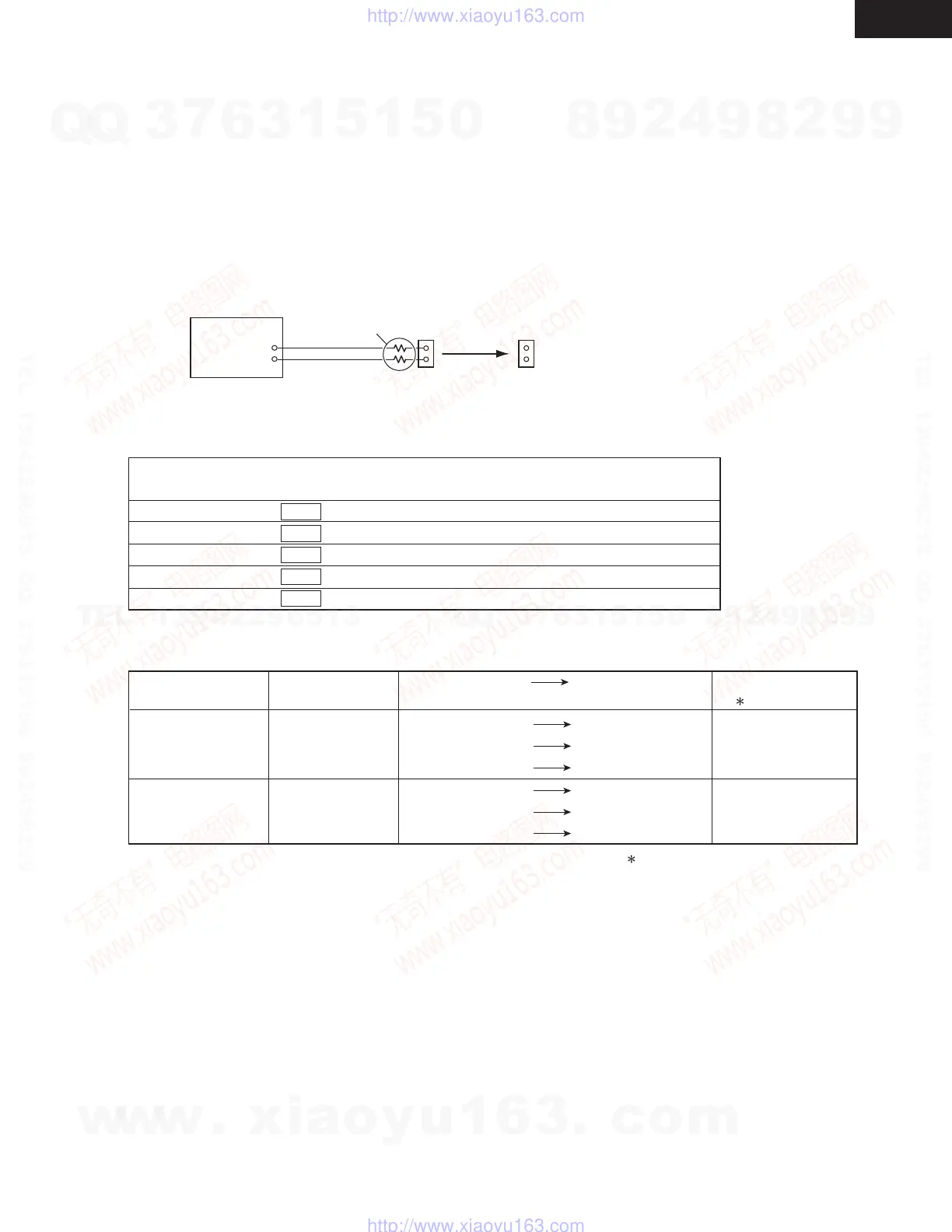

ID+

ID-

Test point

DC voltmeter

Jig terminal

100 ohms

1/4watts

8. Disconnect the dc voltmeter.

9. Press the STANDBY/ON button to turn the power off.

10. Disconnect the ac power cord.

Specifications

( In a stable state)

12 +/- 3 mV

9 +/- 3 mV

Idling currents are stabilized in about

10 minutes after power on.

[When]

Exchange Power transistor (Q6050 - Q6054, Q6060 - Q6064) and Amplifier PC board (NAAF-8911).

Mark

C

L

R

SL

SR

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com

Loading...

Loading...