■ 8

│

GB

│

IE

│

NI

PBSD 600 A1

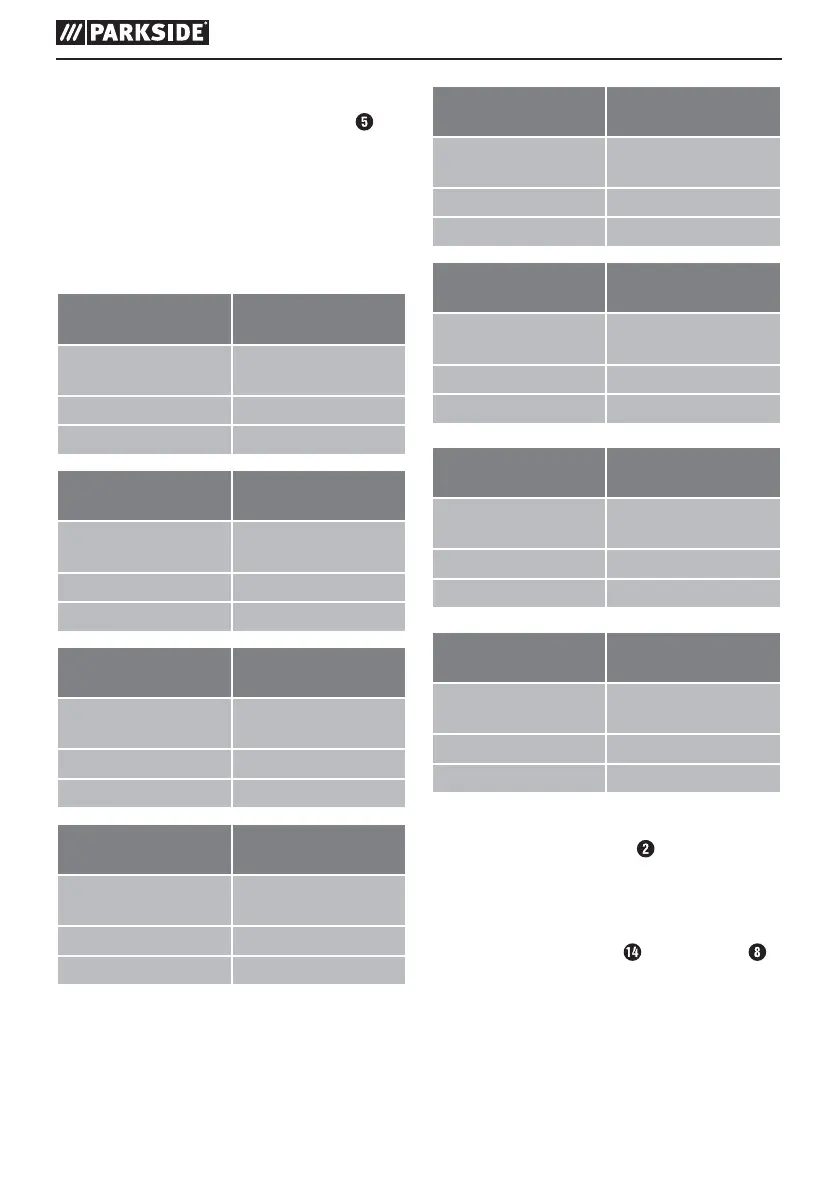

Selecting speed and abrasive belt

You can use the belt speed adjusting wheel to

adjust the speed, even while the appliance is run-

ning. The optimum belt speed is dependent on the

workpiece or material being processed. We rec-

ommend carrying out a practice run to determine

the correct speed. In the table below, you will find

some recommended values which will help you de-

termine which belt and speed to use for which job.

Material/working

area

Softwood

Rough sanding

(grain size)

60

Finishing (grain size) 240

Speed preselection high (5–6)

Material/working

area

Hardwood

Rough sanding

(grain size)

60

Finishing (grain size) 180

Speed preselection high (5–6)

Material/working

area

Chipboard

Rough sanding

(grain size)

60

Finishing (grain size) 150

Speed preselection high (5–6)

Material/working

area

Removing paint/

varnish

Rough sanding

(grain size)

60

Finishing (grain size) ––

Speed preselection high (5–6)

Material/working

area

Rubbing down

paintwork/varnish

Rough sanding

(grain size)

150

Finishing (grain size) 320

Speed preselection low (1–2)

Material/working

area

Removing rust from

steel

Rough sanding

(grain size)

40

Finishing (grain size) 120

Speed preselection medium/high (3–4)

Material/working

area

Plastics

Rough sanding

(grain size)

120

Finishing (grain size) 240

Speed preselection low/medium (2–3)

Material/working

area

Non-ferrous metals

(e.g. aluminium)

Rough sanding

(grain size)

80

Finishing (grain size) 150

Speed preselection medium/high (3–4)

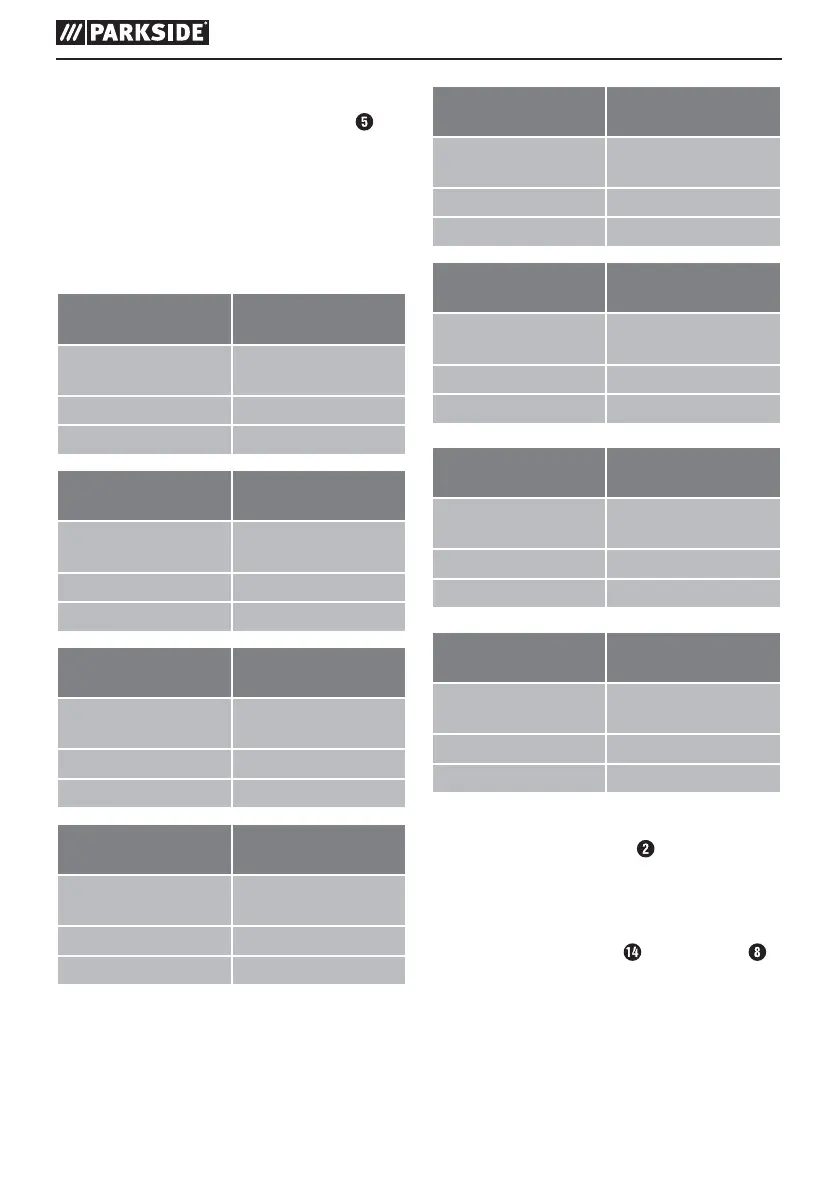

Stationary work

♦ Turn the additional handle to the horizontal

position.

♦ Turn the power tool as shown in the illustration

and place it on a stable worktop.

♦ Fit the two screw clamps

in the recesses

provided and clamp the power tool tightly.

Loading...

Loading...