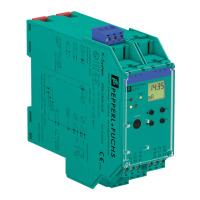

Functional Safety KF**-CRG2-(Ex)1.D

Planning

2017-12

9

3 Planning

3.1 System Structure

3.1.1 Low Demand Mode of Operation

If there are two control loops, one for the standard operation and another one for

the functional safety, then usually the demand rate for the safety loop is assumed

to be less than once per year.

The relevant safety parameters to be verified are:

•the PFD

avg

value (average Probability of dangerous Failure on Demand) and

the T

1

value (proof test interval that has a direct impact on the PFD

avg

value)

• the SFF value (Safe Failure Fraction)

•the HFT architecture (Hardware Fault Tolerance)

3.1.2 High Demand or Continuous Mode of Operation

If there is only one safety loop, which combines the standard operation and

safety-related operation, then usually the demand rate for this safety loop is

assumed to be higher than once per year.

The relevant safety parameters to be verified are:

• the PFH value (Probability of dangerous Failure per Hour)

• Fault reaction time of the safety system

• the SFF value (Safe Failure Fraction)

•the HFT architecture (Hardware Fault Tolerance)

3.1.3 Safe Failure Fraction

The safe failure fraction describes the ratio of all safe failures and dangerous

detected failures to the total failure rate.

SFF = (

s

+

dd

) / (

s

+

dd

+

du

)

A safe failure fraction as defined in IEC/EN 61508 is only relevant for elements or

(sub)systems in a complete safety loop. The device under consideration is

always part of a safety loop but is not regarded as a complete element or

subsystem.

For calculating the SIL of a safety loop it is necessary to evaluate the safe failure

fraction of elements, subsystems and the complete system, but not of a single

device.

Nevertheless the SFF of the device is given in this document for reference.

Functional Safety KF**-CRG2-(Ex)1.D

Loading...

Loading...