BTQ Series

EN

QUICK BTQSeries INSTALLATION AND USER’S MANUAL - REV003A

11

4 - Installation

4.2 - Thruster

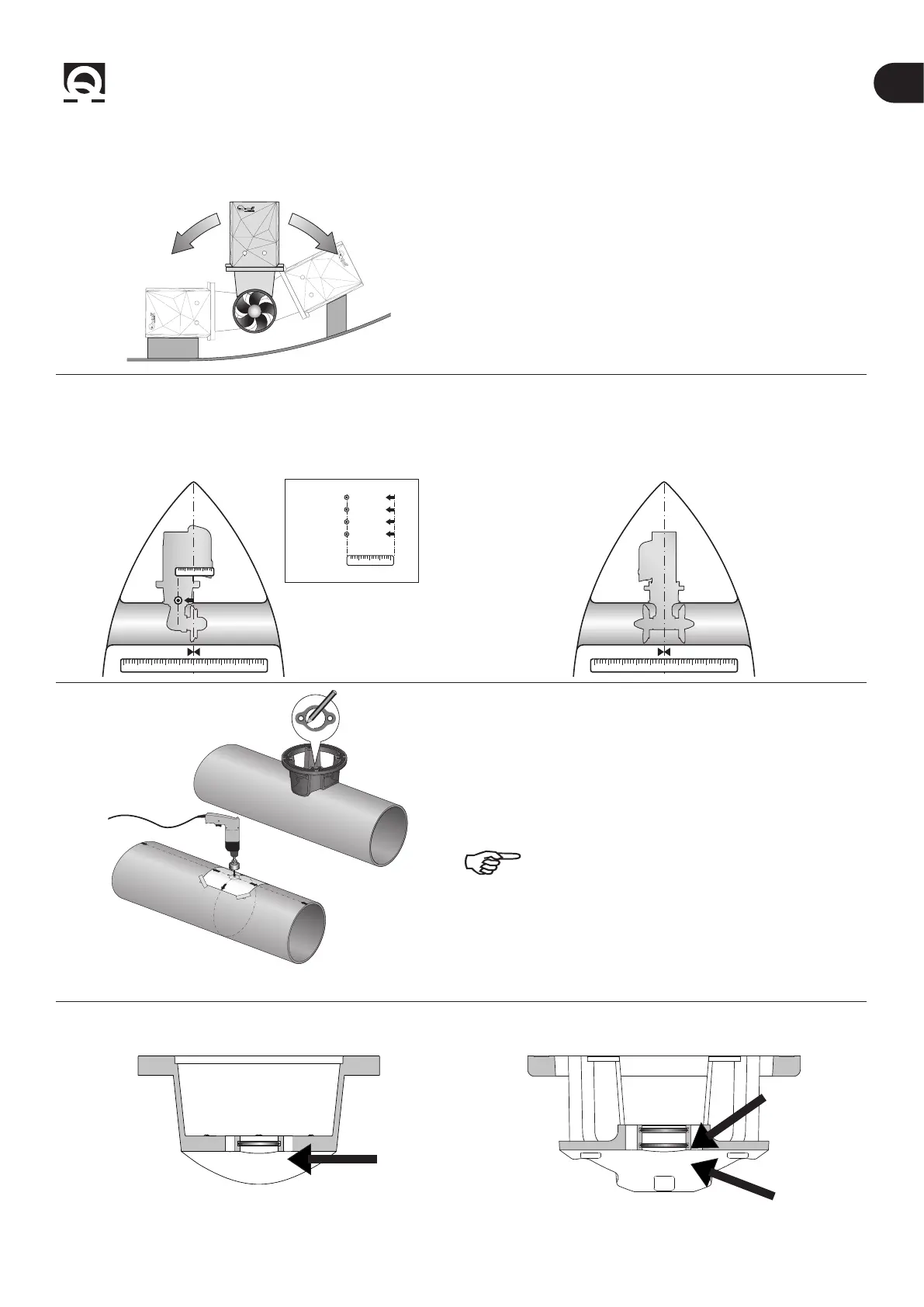

• The thruster can be installed at any angle within 90º from

the vertical.

• If the electric motor is positioned at an angle of more than

30° from the vertical, an appropriate support (saddle) must be

installed.

SINGLE PROPELLER DOUBLE PROPELLER

• To position the thruster in the tube, nd the half-way point

of the tube and move by the value indicated (left or right, see

box) in the diagram below so that the propeller is positioned

exactly in the middle of the inner length of the tunnel.

• To position the thruster in the tube, nd the half-way point

of the tube and move by the value indicated (left or right, see

box) in the diagram below so that the propeller is positioned

exactly in the middle of the inner length of the tunnel.

10 2 3 4 5 6 7 8 9 10

10 2 3 4

10 2 3 4

BTQ110 50 mm

BTQ125 50 mm

BTQ140 50 mm

BTQ180 50 mm

10 2 3 4 5 6 7 8 9 10

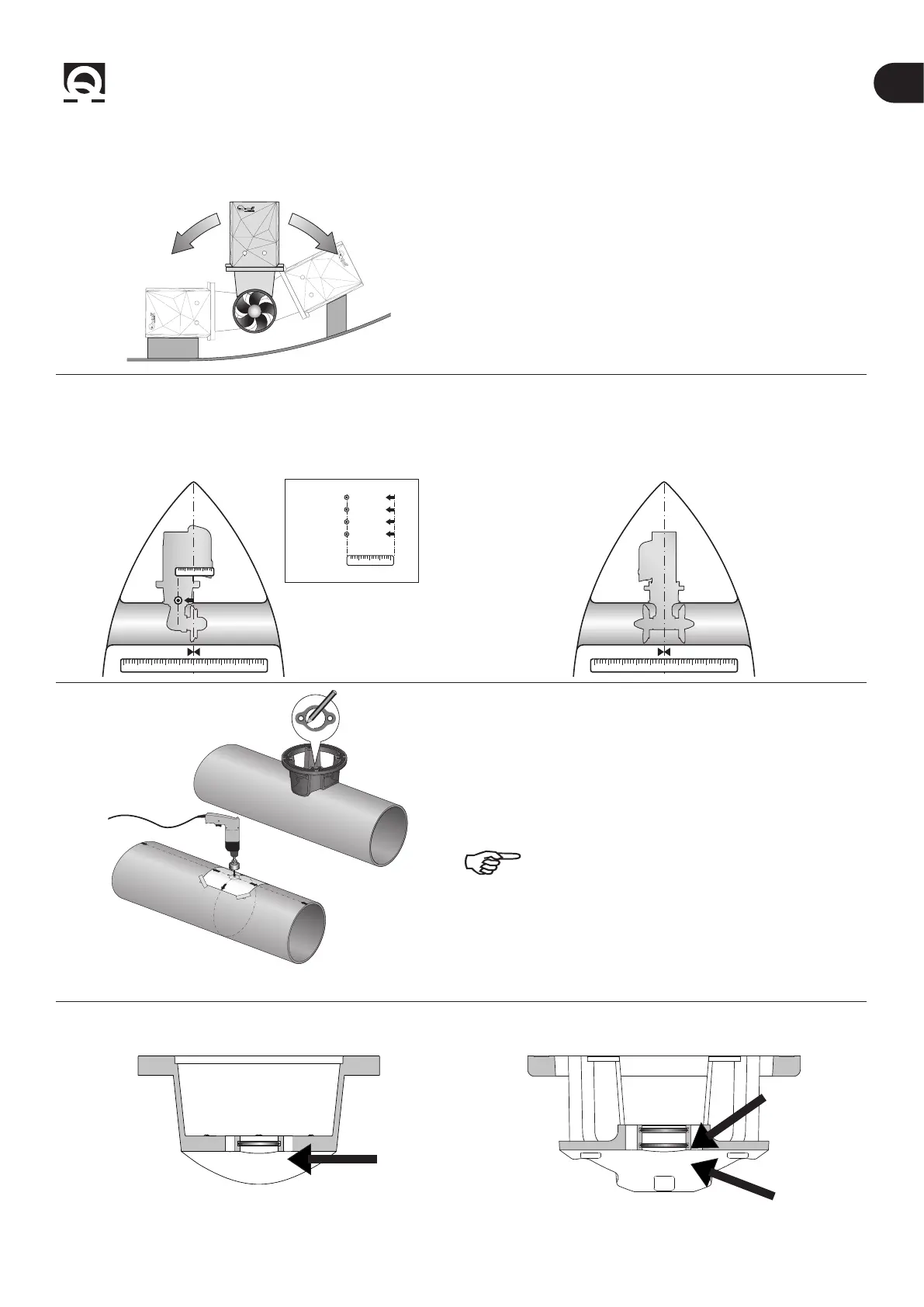

• Use the ange to mark the centre of the holes on the tube.

• Fix the drilling template on the reference points, making

sure they are aligned with precision at the half-way point of

the tube.

N.B. All holes must be exactly aligned with the half-

way point of the tunnel, since tolerance between

propeller and tunnel is minimal.

• Take care that there are no resin residues in the contact

area between ange and tube; this could cause misalignment.

Any resin residues and any other hindrance to correct

contact must be removed with sandpaper.

BTQ Ø110/125 BTQ Ø140/185/250/300

• Insert one O-ring into the special seat inside the ange. • Insert two O-rings into the special seats inside the ange.

Loading...

Loading...