12

Tubing

4.0 INSTALLATION

4.4.2.5 Oil Level Adjustment for

Long Line Set Applications

Additional oil will need to be added if refrigerant is

added during installation. Below is the equation for

the oil level adjustment and the compressor name

plate oil charge for the different outdoor units.

Oil to be Added = [(Charge Adjustment + OD

Unit Name Plate Refrigerant Charge (oz.)) ×

(0.022) – [(0.10) × (Compressor Name Plate Oil

Charge (oz.))]

Example: An application requires 125ft of line set

with a liquid line diameter of 3/8”, Charge Adjust-

ment = 66 oz., Name Plate Charge = 212 oz.,

Name Plate Oil Charge = 40 oz., Oil to be Added =

((66 oz. + 212 oz.) × .022) – (.10 × 40 oz.) = 2 oz.

4.4.2.6 Capacity Losses

Long line lengths can result in a reduction in capac-

ity due to vapor line pressure drop and heat gain or

loss. Refer to Table 2 for capacity loss multipliers

for various vapor line diameters and equipment line

lengths. This table does not account for any capac-

ity loss due to heat gain or loss from the environ-

ment. It is extremely important not to oversize the

vapor line to minimize capacity loss at the expense

of proper oil return. If the table shows an “NR” for

a particular vapor line diameter and length, or, if a

vapor line diameter is not listed, oil return will not be

adequate.

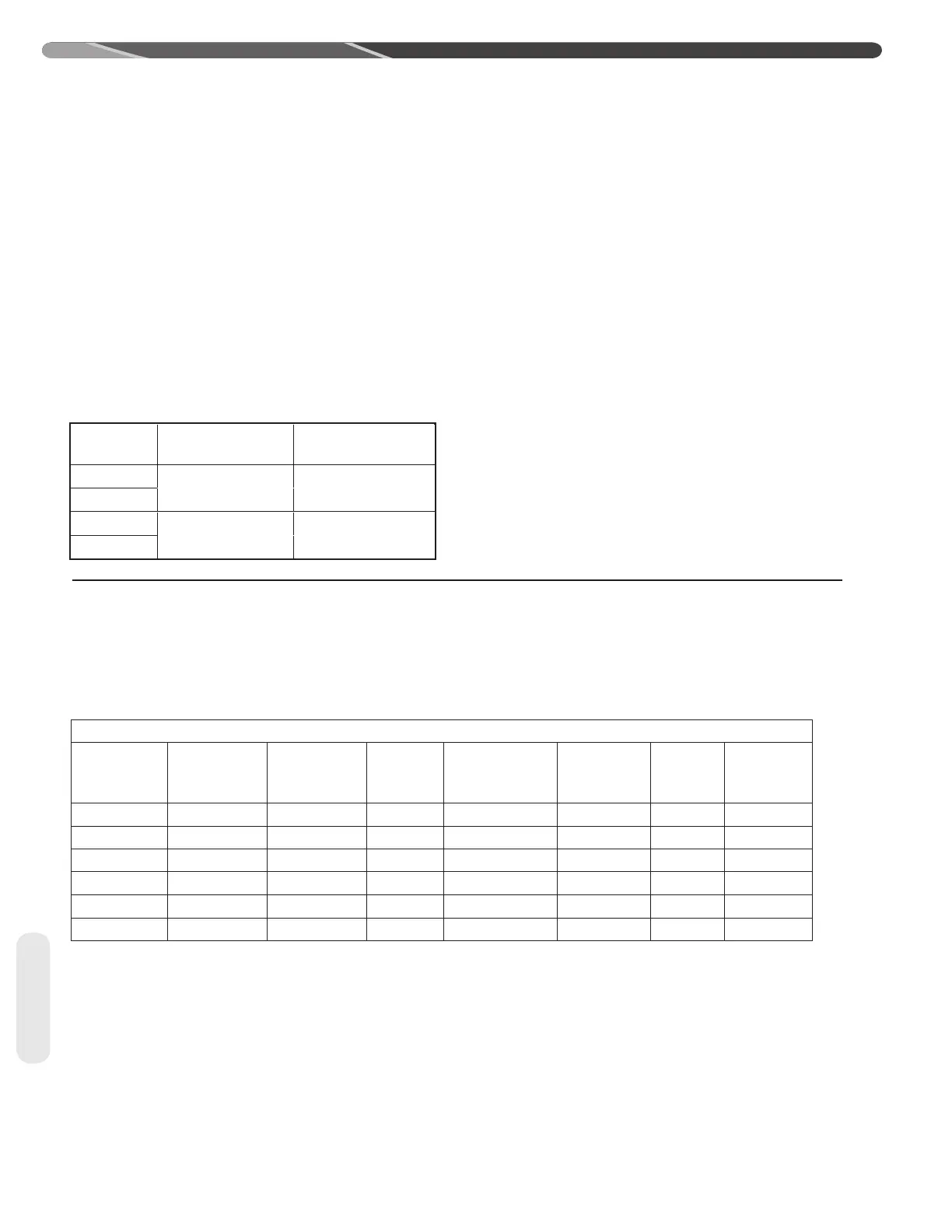

OD Model

Compressor

Nameplate Oil

Charge (oz)

(-)P1724

ZPV0212E-ZE9-130 40

(-)P1736

ZPV0342E-ZE9-130 40

(-)P1748

(-)P1760

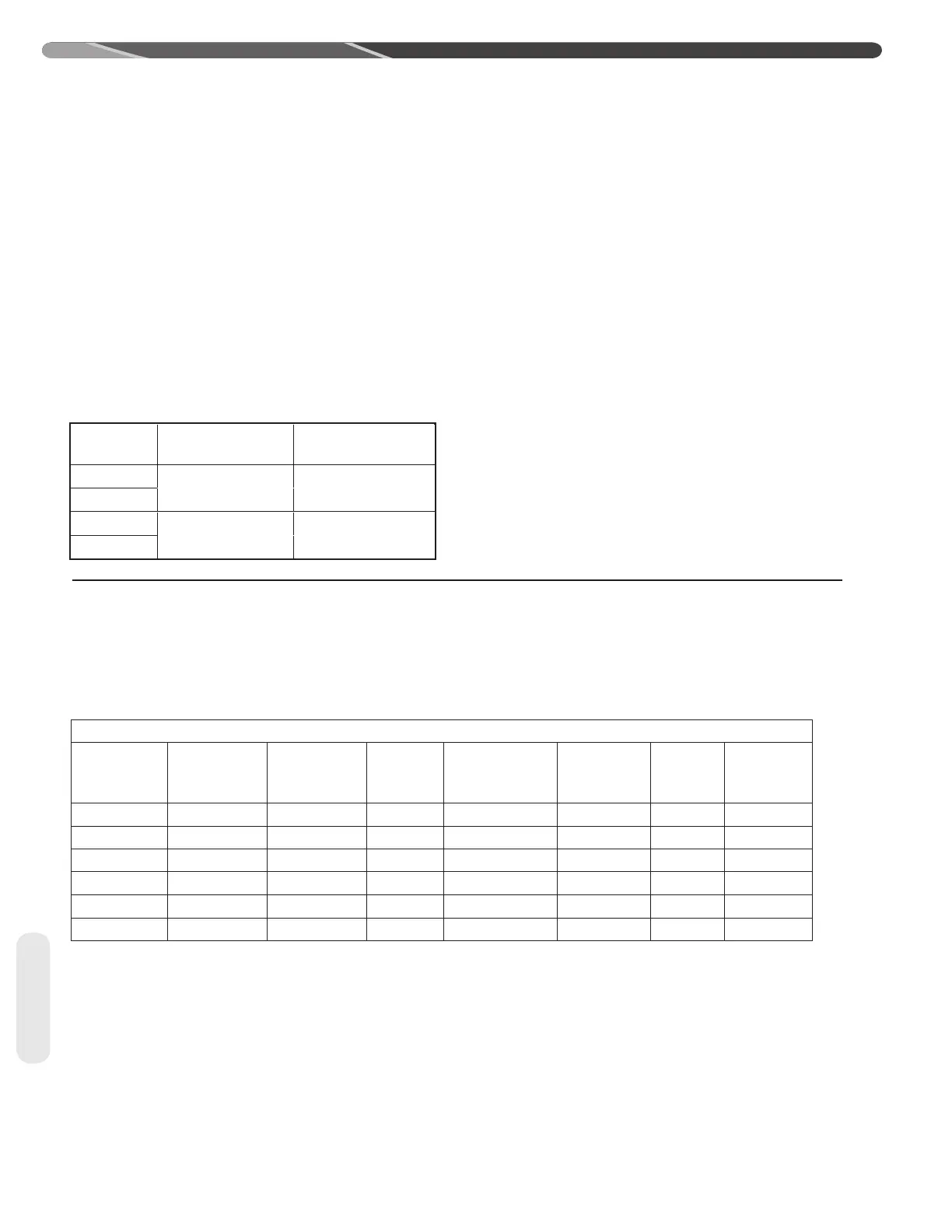

ƋƵŝǀĂůĞŶƚ>ĞŶŐƚŚĨŽƌ&ŝƚƚŝŶŐƐĨƚŵ

>ŝŶĞ^ŝnjĞ

ŝŶŵŵ

ϵϬΣ^ŚŽƌƚ

ZĂĚŝƵƐ

ůďŽǁ

ϵϬΣ>ŽŶŐ

ZĂĚŝƵƐ

ůďŽǁ

ϰϱΣ

ůďŽǁ

^ŽůĞŶŽŝĚ

sĂůǀĞ

ŚĞĐŬ

sĂůǀĞ

^ŝŐŚƚ

'ůĂƐƐ

&ŝůƚĞƌ

ƌŝĞƌ

ϯϴϵϱϯ ϭϯϬϰϬ ϬϴϬϮϰ ϬϯϬϬϵ ϲϭϴϯ ϰϭϮϮ ϬϰϬϭϮ ϲϭϴϯ

ϭϮϭϮϳϭ ϭϰϬϰϯ ϬϵϬϮϳ ϬϰϬϭϮ ϵϮϳϰ ϱϭϱϮ ϬϲϬϭϴ ϲϭϴϯ

ϱϴϭϱϴϴ ϭϱϬϰϲ ϭϬϯϬ ϬϱϬϭϱ ϭϮϯϲϲ ϲϭϴϯ ϬϴϬϮϰ ϲϭϴϯ

ϯϰϭϵϬϱ ϭϵϬϱϴ ϭϯϬϰϬ ϬϲϬϭϴ ϭϰϰϮϳ ϳϮϭϯ ϬϵϬϮϳ ϲϭϴϯ

ϳϴϮϮϮϯ ϮϯϬϳϬ ϭϱϬϰϲ ϬϳϬϮϭ ϭϱϰϱϳ ϴϮϰϰ ϭϬϯϬ ϲϭϴϯ

ϭͲϭϴϮϴϱϴ ϮϳϬϴϮ ϭϴϬϱϱ ϬϵϬϮϳ ϮϮϲϳϭ ϭϮϯϲϲ ϭϱϬϰϲ ϲϭϴϯ

Table 1

Refrigerant tubing is measured in terms of actual

length and equivalent length. Actual length is used

for refrigerant charge applications. Equivalent

length takes into account pressure losses from tub-

ing length, ttings, vertical separation, accessories,

and lter driers. The table below references differ-

ent commonly used equivalent lengths.

4.4.3 Line Set Length and Fitting Losses

Loading...

Loading...