Rockwell Automation Publication TLP-IN001A-EN-P - October 2019 15

Kinetix TLP Servo Motors with 046…235 mm Frame Size

Environmental Specifications

Always store motors in a clean and dry location within the environmental conditions.

Environmental Ratings

Motor Accessories

The following accessories are available for Kinetix TLP servo motors.

2090-Series Motor Cables

Factory manufactured feedback, power, and brake cables are available in standard cable lengths. They provide the sealing that is needed to achieve

environmental ratings and shield termination. If you choose to build your own cables, connector kits available for Kinetix TLP motors are described

in the Kinetix Motion Accessories Specifications Technical Data, publication KNX-TD004

.

Contact your nearest Rockwell Automation sales office or refer to the Kinetix Motion Accessories Technical Data, publication KNX-TD004

, for

information about available 2090-Series cables for Kinetix TLP motors.

Shaft Seal Kits

Shaft seal kits are available, as are replacement kits for field installation. A shaft seal provides a barrier that prevents moisture and particles from

entering the motor bearings. Shaft seals are made of nitrile and kits and require lubrication to reduce wear.

Shaft Seal Kit Selection

See Shaft Seal Kits for Kinetix TLP Installation Instructions, publication 2090-IN044, for instructions on how to install a shaft seal.

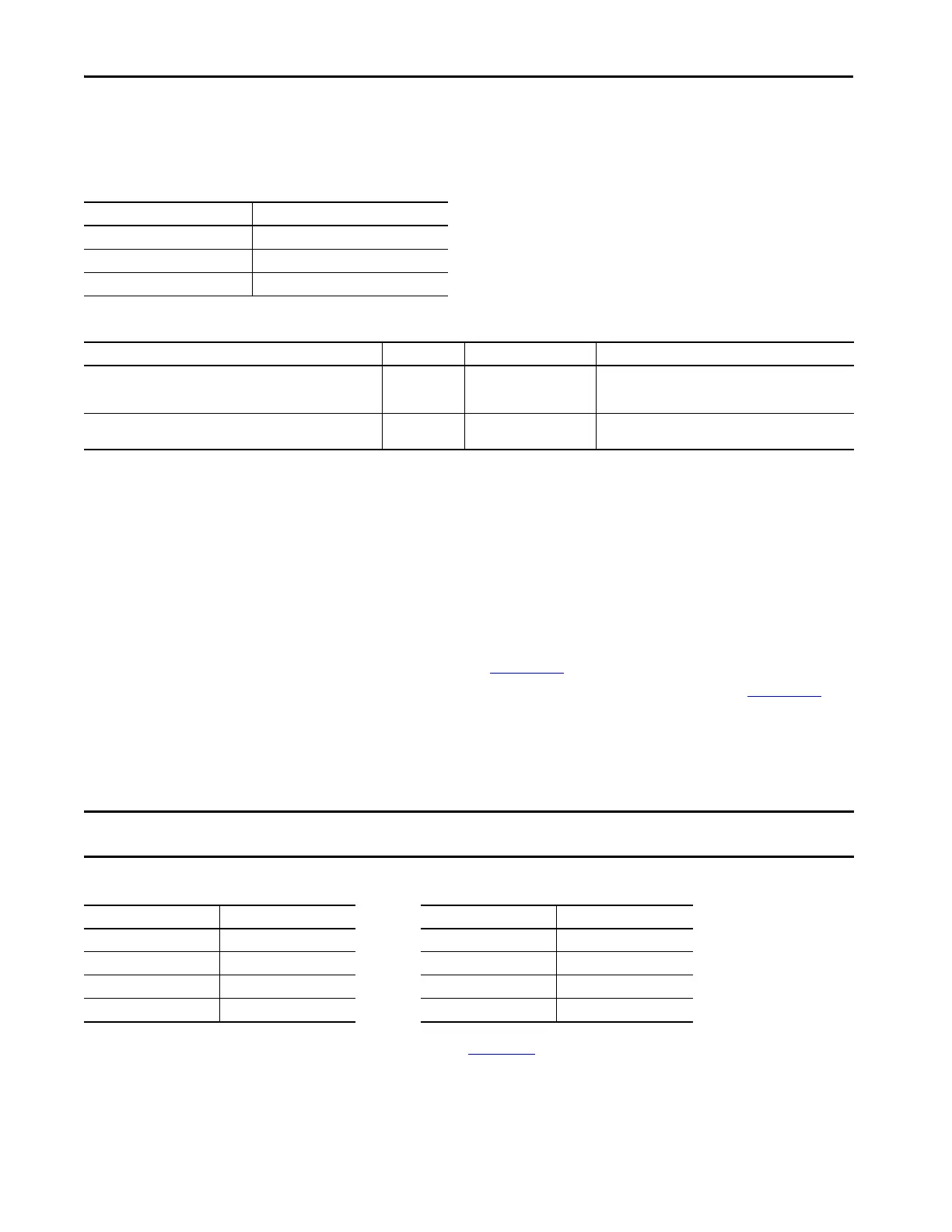

Environmental Specifications

Attribute Value

Temperature, operating 0…40 °C (32…104 °F)

Temperature, storage -10…+80 °C (-14 …+176 °F)

Relative humidity 20…95% noncondensing

Kinetix TLP Motors IP Rating

(1)

(1) IP rating descriptions are for reference only. Refer to the international standards for more complete rating descriptions.

Dust Protection Liquid Protection

On-motor cable connectors. IP30

Protection from objects with a

diameter of 2.5 mm (0.098 in.)

or more.

No protection from liquids.

Motor with shaft seal and Bulletin 2090 environmentally sealed cable

connectors.

IP65

(2)

(2) IP40 without shaft seal installed.

Total protection from dust. Protected against low-pressure jets of water from all directions.

IMPORTANT

Shaft seals are subject to wear and require periodic inspection and replacement. Replacement is recommended every 3 months, not to exceed 12 months,

depending on use.

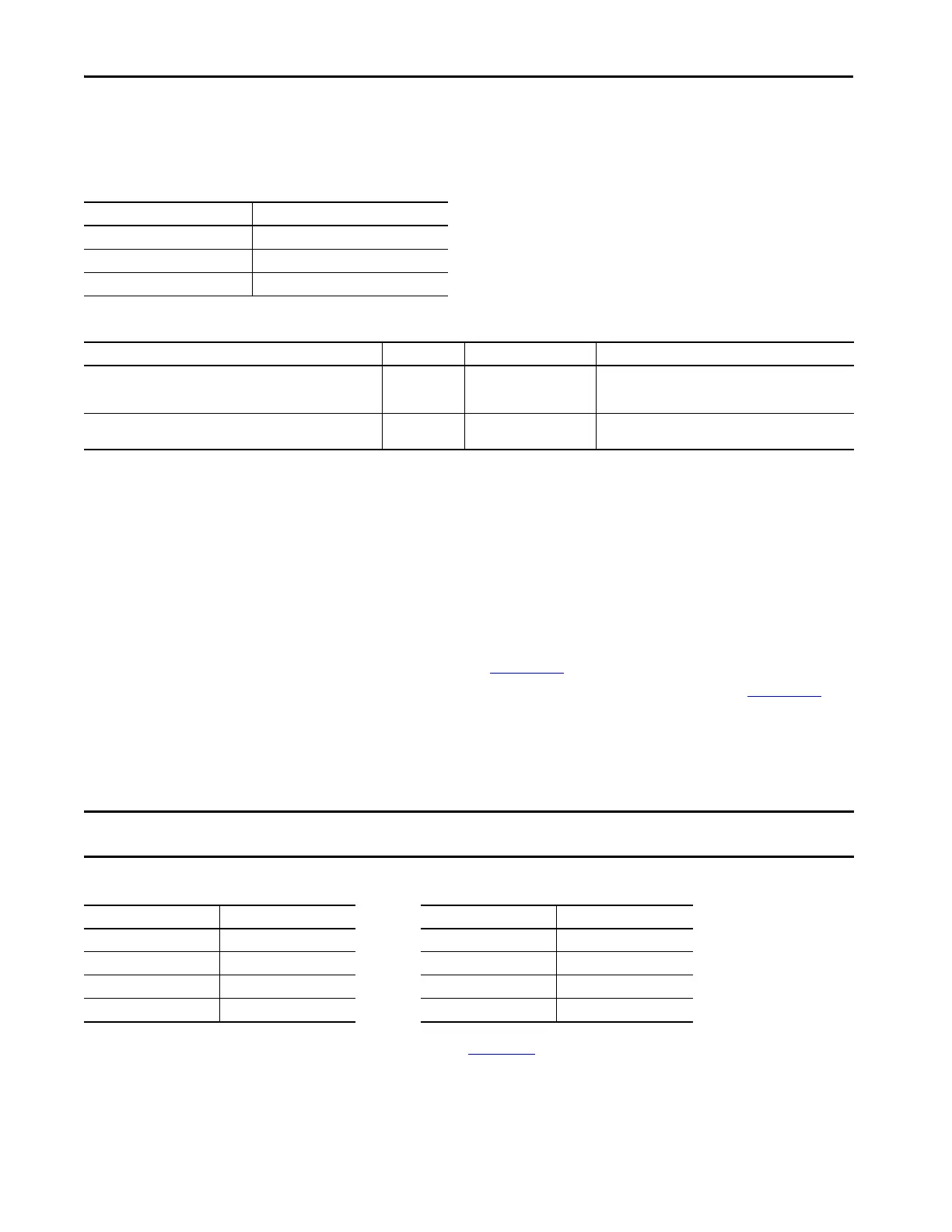

Motor Cat. No. Shaft Seal Kit Cat. No. Motor Cat. No. Shaft Seal Kit Cat. No.

TLP-A046 TLP-SSN-F046 TLP-A115 TLP-SSN-F115

TLP-A070 TLP-SSN-F070 TLP-A145 TLP-SSN-F145

TLP-A090 TLP-SSN-F090 TLP-A200 TLP-SSN-F200

TLP-A100 TLP-SSN-F100 TLP-A235 TLP-SSN-F235

Loading...

Loading...