www.scheppach.com service@scheppach.com +(49)-08223-4002-99 +(49)-08223-4002-58

28 І GB

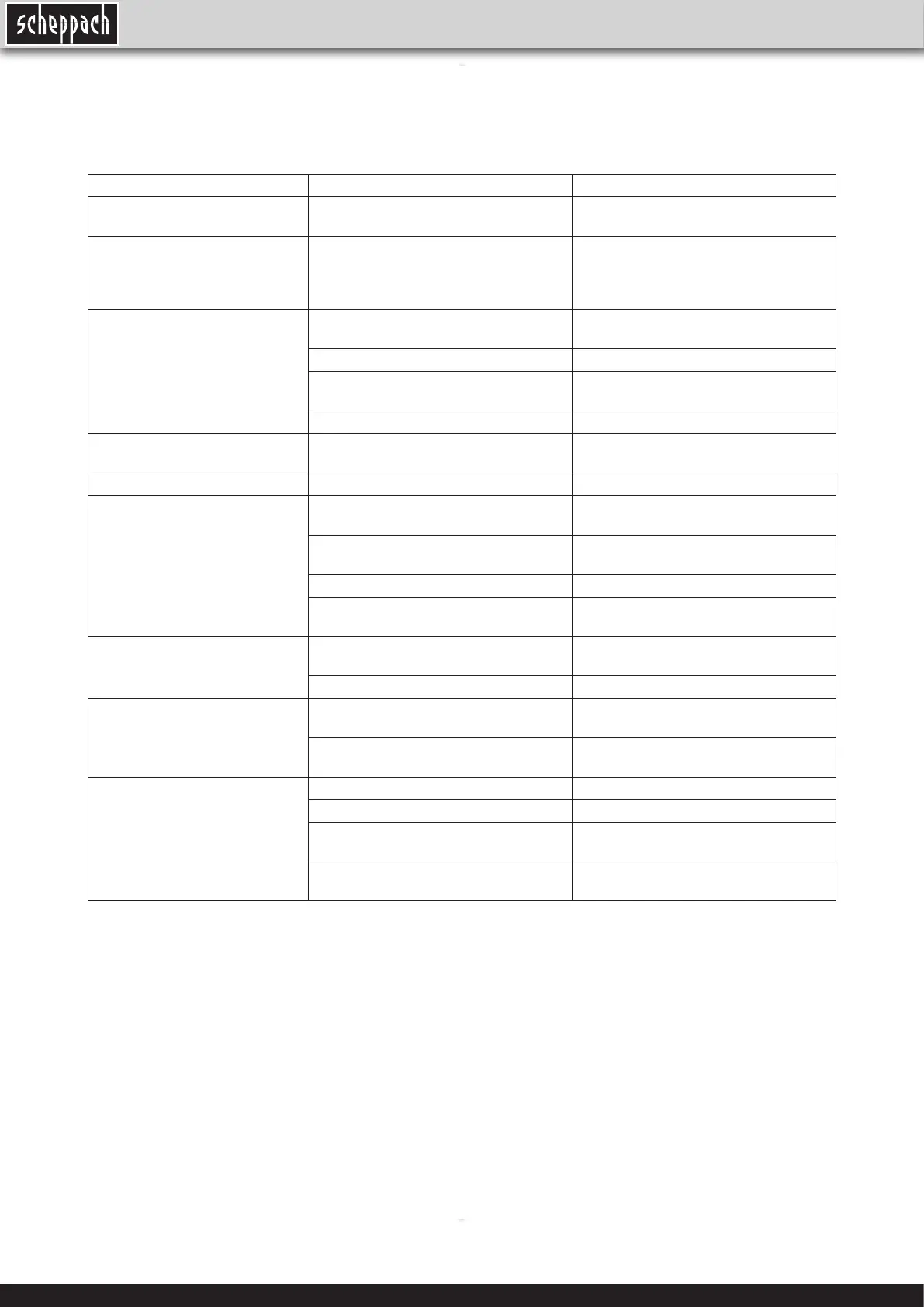

Troubleshooting

Warning:

Turn switch off and always remove plug from the power source before trouble shooting.

Trouble Problem Remedy

Quill returns too slowy or too

quickly

Spring has improper tension. Adjust spring tension. See “Quill return

spring”.

Chuck wiII not stay attached to

spindle. It wiII falls off when try-

ing to install.

Dirt, grease or oil on the tapered inside

surface of the chuck or on the spindle’s

tapered surface.

Using household detergent, clean the

tapered surfaces af chuck and spindle ta

remove all dirt, grease and oil. See “In-

stalling the chuck”.

Noisy operation 1. Incorrect belt tension 1. Adjust belt tension. See „

Choosing

speed and tensioning belt

“.

2. Dry spindle. 2. Dublicate spindle.

3. Loose spindle pulley 3. Check tightness of retaining nut on

pulley, and tighten if necessary

4. Loose motor pulley. 4. Tighten set screw in motor pulley

Wood splinters on underside. No “backup material” behind work piece. Use “backup material”. See “

Positioning

table and workpiece

”.

Workpiece tom loose from hand. Not supported or clamped property. Support work piece or clamp it.

Drill bit bums. 1. Incorrect speed. 1. Change speed. See “Choosing speed

and

tensioning belt”.

2. Chips not coming out of hole. 2. Retract drill bit frequently to remove

chips.

3. Dull drill bit 3. Resharpen drill bit.

4. Feeding too slowy 4. Feed fast enough ta allow drill bit to

cut.

Drill leads off...hole not round. 1. Hard grain in wood or lengths of cut-

ting lips and/or angle not equal

1. Resharpen drill bit correctly.

2. Bent drill bit. 2. Replace drill bit.

Drill bit binds in work piece. 1. Work piece pinching drill bit or exces-

sive feed pressure.

1. Suppart work piece at clamp it. See

“Positioning table and work piece”.

2. Improper belt tension. 2. Adjust belt tension. See “Choosing

speed and tensioning belt”.

Excessive drill bit run- out or wob-

ble.

1. Bent drill bit 1. Use a straight drill bit..

2. Wom spindle bearings. 2. Replace bearings.

3. Drill bit not properly installed in chuck. 3. Install drill properly. See “Installing drill

bits”.

4. Chuck not properly installed. 4. Install chuck properly. See “Installing

the chuck”.