4

SR80/185T - SR100/185T 1.0.0 - 2009

Motor: Spesialutviklet reversibel DC-motor.

Girhus: 6M¡YDQQVEHVWDQGLJEURQVMH.XOHODJUHSnSURSHOODNVHO

Kule og glidelager komb. på drivaksel.

Motorbraket: 6M¡YDQQVEHVWDQGLJDOXPLQLXP

Galvanisk isolert fra motor

Tunnel: .U\VVYHYHWJODVV¿EHU

Propell: 5-blads skew "Q"-propell i komposittmateriale.

Batterier: Minimum anbefalt batteri størrelse.

(Kaldstart kapasitet etter DIN/SAE std.)

SR 80/185T 12V : 550 CCA DIN/1045 CCA SAE

SR 80/185T 24V : 300 CCA DIN/570 CCA SAE SR

100/185T 12V : 750 CCA DIN/1425 CCA SAE

SR 100/185T 24V : 400 CCA DIN/760 CCA SAE

Drift tid: 6 PLQHOOHUJMHQQRPVQLWWOLJLQQHQHQEHJ-

renset tidsperiode.

Sikkerhet: Elektronisk tidsforsinkelse forhindrer motorskade ved

rask retningsendring.

Motoren stanser automatisk ved overopphetning (slår

VHJDXWRPDWLVNSnHWWHUQHGNM¡OLQJ

Fleksibel kobling mellom drivaksel og motor beskytter

gir hvis propell blir blokkert.

S-Link panelet slår av trusteren og feller den inn 6

minutter etter siste gangs bruk

Integrert microprossessor føler hele tiden på

UHOHHWUHGXVHUHUVOLWDVMHRJULVNIRU´KHQJ´Sn

relé. Trusteren vil stoppe automatisk etter 3

PLQXWWHURPGHWRSSVWnU´KHQJ´SnUHOpHOOHU

om trøsteren går kontinuerlig i 3 minutter.

Motor: Custom made reversible DC-motor.

Gearhouse: Seawater resistant bronze. Ballbearing at

propellershaft and combination of ballbearing and slide

bearing at driveshaft.

Motor bracket: Seawater resistant aluminium,

galvanicly insulated from motor

Tunnel: Cross spun with rowing G.R.P tunnel

Propeller: 5 blade skew "Q"-propeller,

¿EUHJODVVUHLQIRUFHGFRPSRVLWH

Batteries:

Minimum recommended battery capacity

(cold crank capacity by DIN/SAE standard)

SR 80/185T 12V : 550 CCA DIN/1045 CCA SAE

SR 80/185T 24V : 300 CCA DIN/570 CCA SAE SR

100/185T 12V : 750 CCA DIN/1425 CCA SAE

SR 100/185T 24V : 400 CCA DIN/760 CCA SAE

Max. use: 6 PLQRUDSSUZLWKLQDOLPLWHGWLPHIUDPH

Safety

:

Electronic time-delay device protects against sudden

change of drive direction. Electric thermal cut-off switch

in electromotor protects against over heating (auto reset

when electro motor cools down).

Flexible coupling between electro-motor and driveshaft

protects electromotor and gearsystem if propeller gets

MDPPHG

S-link panel shuts off automatically and retracts thruster

6 minutes after last use.

Integrated microprocessor monitors solenoids,

reducing wear and risk of solenoid lock-in. Auto-stop of

thruster in case of accidental solenoid lock-in or if run

signal is continous for more than 3 minutes

7HFKQLFDOVSHFL¿FDWLRQV

GB

7HNQLVNHVSHVL¿NDVMRQHU

N

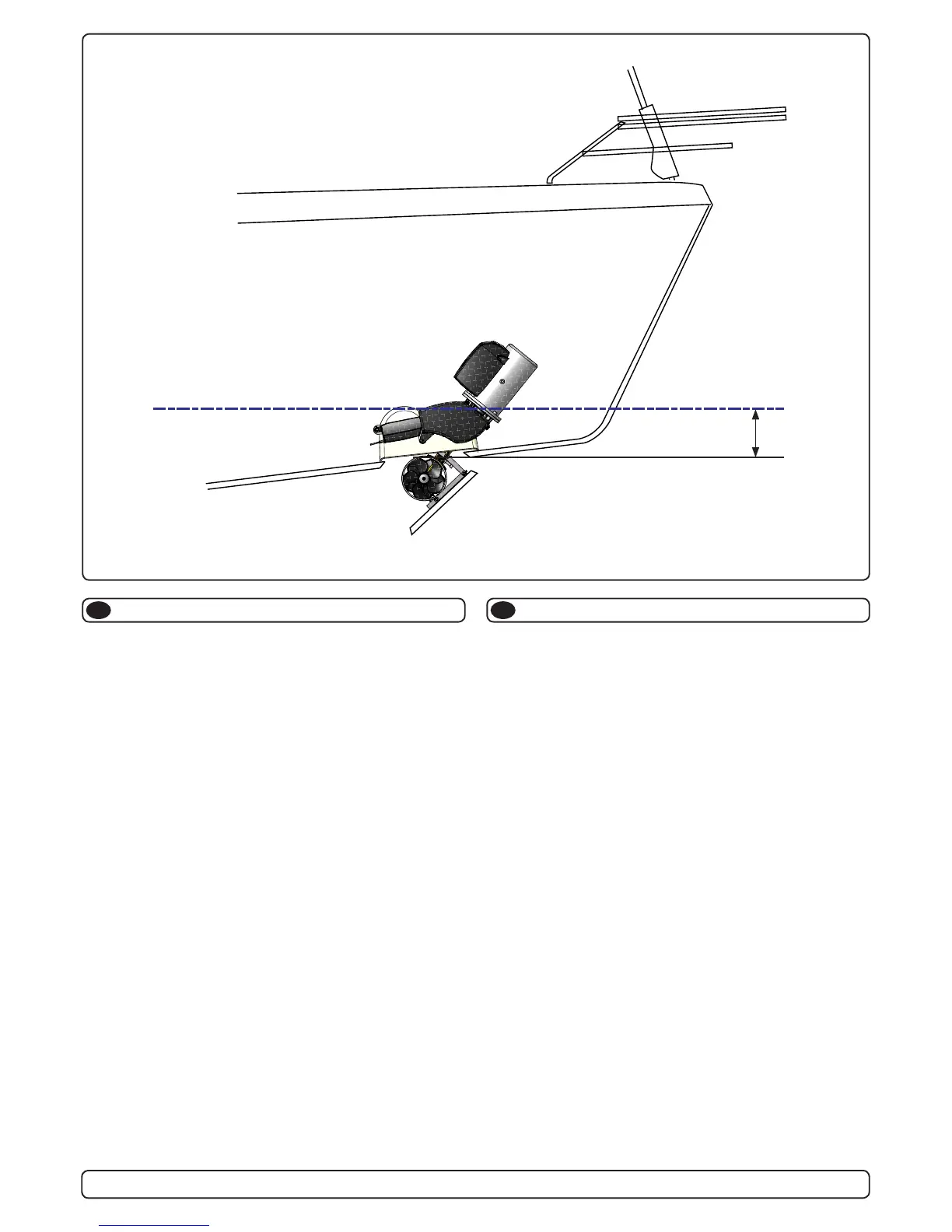

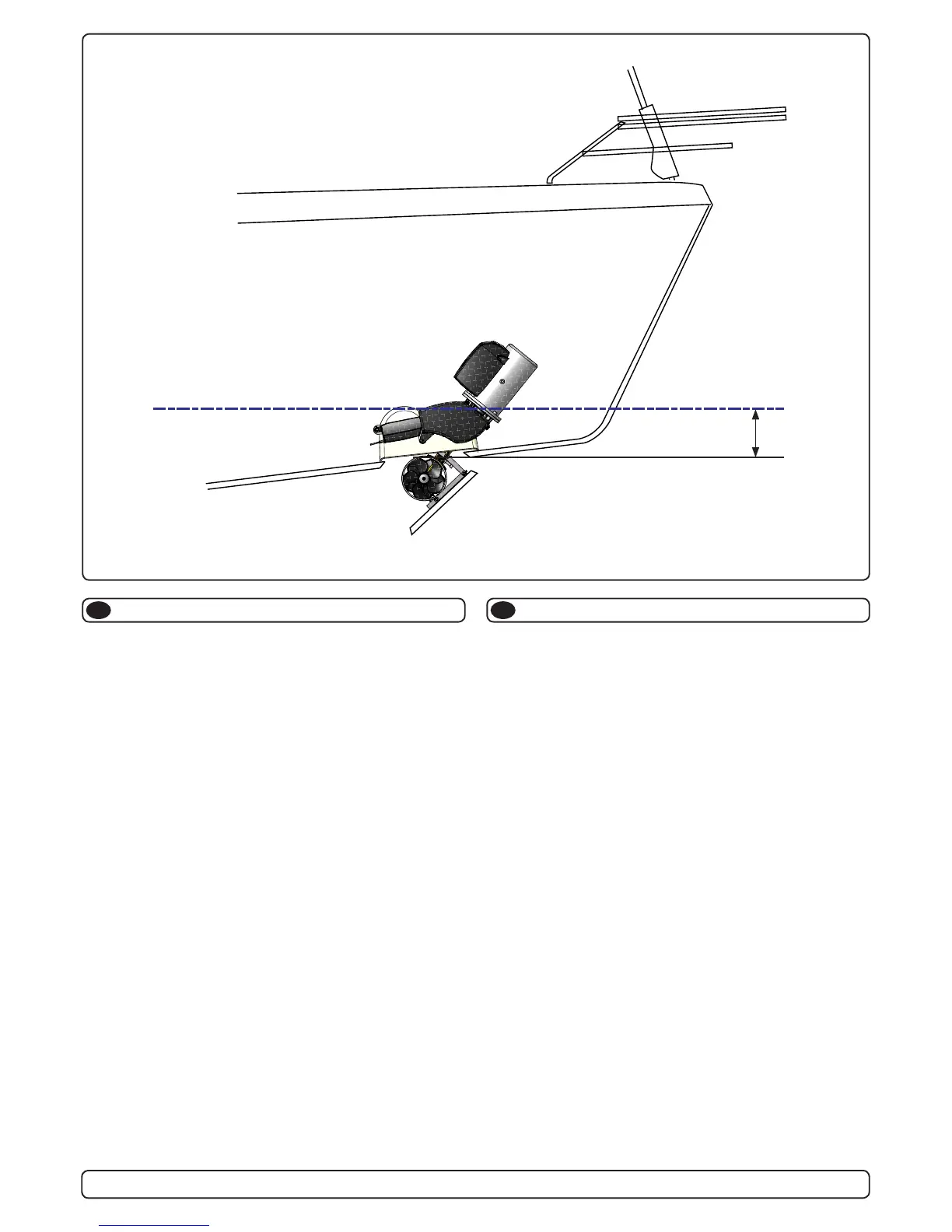

Min. 185mm

WATERLINE

Loading...

Loading...