16

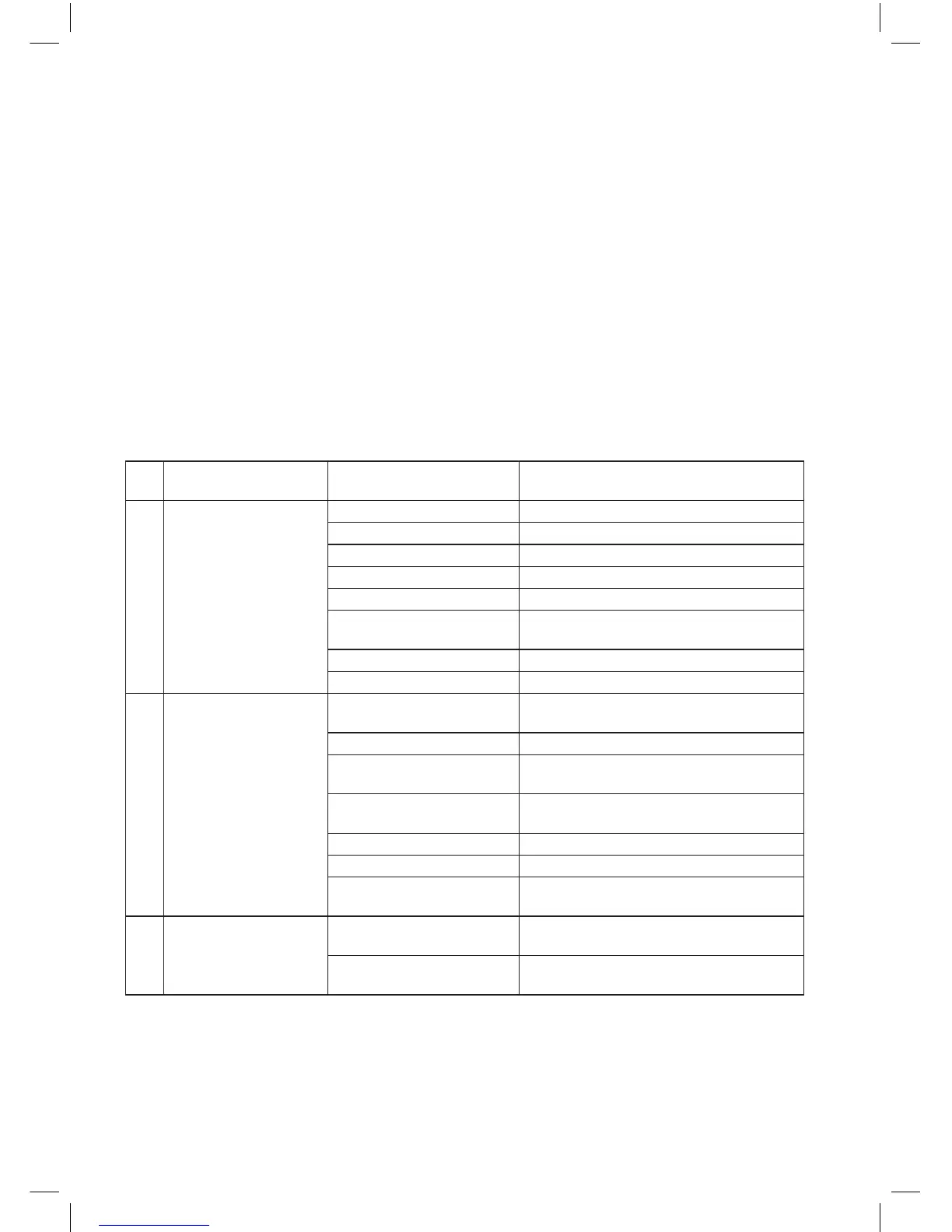

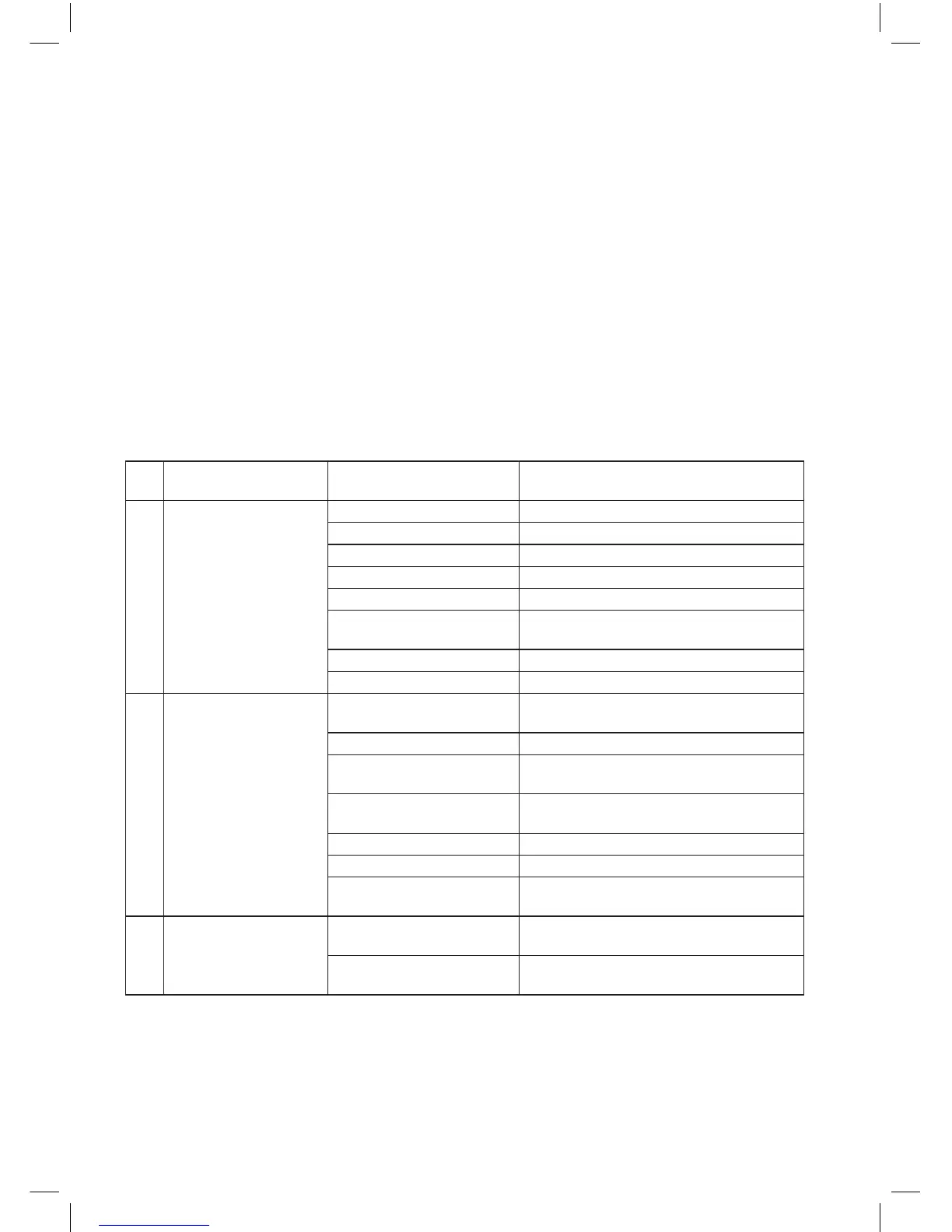

7. Motor Troubleshooting Chart

Sr.

No.

Trouble Cause Remedy

1 Hot bearings Excessive belt pull Decrease belt tension.

Pulley too far away Move pulley closer to bearing.

Pulley dia. too small Use larger pulley.

Misalignment Correct by realignment of drive.

Broken ball or rough races Replace bearings.

Excess lubricant Reduce quantity of grease

(Bearing should be lled only half).

Overloaded bearings Check alignment, side thrust & end thrust.

Bearing running dry Regrease the bearing.

2 Motor connected but

does not start

No supply voltage/ One

phase open/ Voltage too low

Check voltage on each phase.

Motor may be overloaded Reduce load or start at no load.

Control gear defective Examine each step of the control gear for

bad contacts or open circuit.

Starting torque too high If with autotransformer starting, change to

higher tap.

Rotor defective Look for broken rings.

Short circuit to earth Check with Megger.

Fault in starter or star/delta

switch

Check contacts & connections.

3 Motor runs & then stops

down

Power failure Check for loose connections to line, fuses &

control gear.

Over load Examine overload trips & see that they are

set at approx. 150% of full load current.

IS: 7816: Guide for testing insulation

resistance of rotating machines.

IS: 9628: Specication for Three phase

induction motors with type of protection

‘n’.

IS: 6381: Specication for construction and

testing of apparatus with type of protection

‘e’.

IS: 12065: Permissible limits of noise level

for rotating electrical machines.

IS: 12075: Mechanical vibration of rotating

electrical machines with shaft heights

56mm and higher – Measurement,

Evaluation and Limits of Vibration severity.

IS/IEC: 60034-1: Rotating electrical

machines – Part 1: Rating and

Performance.

IS/IEC: 60034-5: Degree of protection for

rotating electrical machines.

EN: 60204: Safety of machinery –Electrical

equipment of machines.

Loading...

Loading...