Operating and Programming — Milling Page 40 808D

Create Part

Program

Part 2

s

Basic Theory

→

Hole

centering

The easiest way to

center drill a hole

prior to drilling is to

use either CY-

CLE81 or CY-

CLE82

CYCLE81: With-

out delay at cur-

rent hole depth

CYCLE82: With

delay at current

hole depth

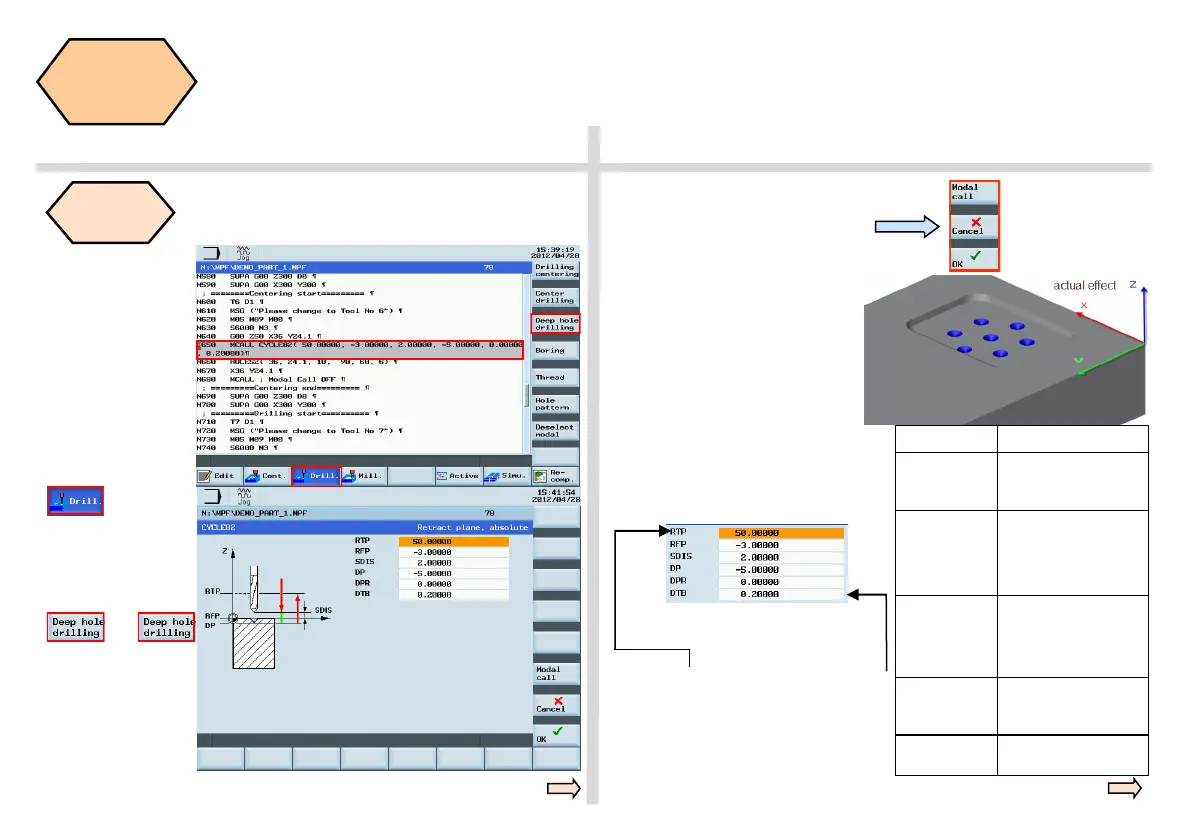

Select “Deep hole

drilling” using the

vertical SKs , and

then select “Deep

hole drilling” ,and

parameterize the

cycle according to

requirements.

N325 MCALL CYCLE82( 50.000, -3.000,

2.000, -5.000, 0.000, 0.200)

N330 X20 Y20 ; Hole will be centered

N335 X40 Y40 ; Hole will be centered

N340 MCALL

N345 X60 Y60 ; Hole will not be

centered

With the “OK” SK, the values and

cycle call will be transferred to

the part program as shown be-

low.

This will drill a hole at the current

position.

With the Modal call SK, holes will

be centered at subsequent

programmed positions until

cancelled with the MCALL

command in the part program.

The information is transferred as

shown below.

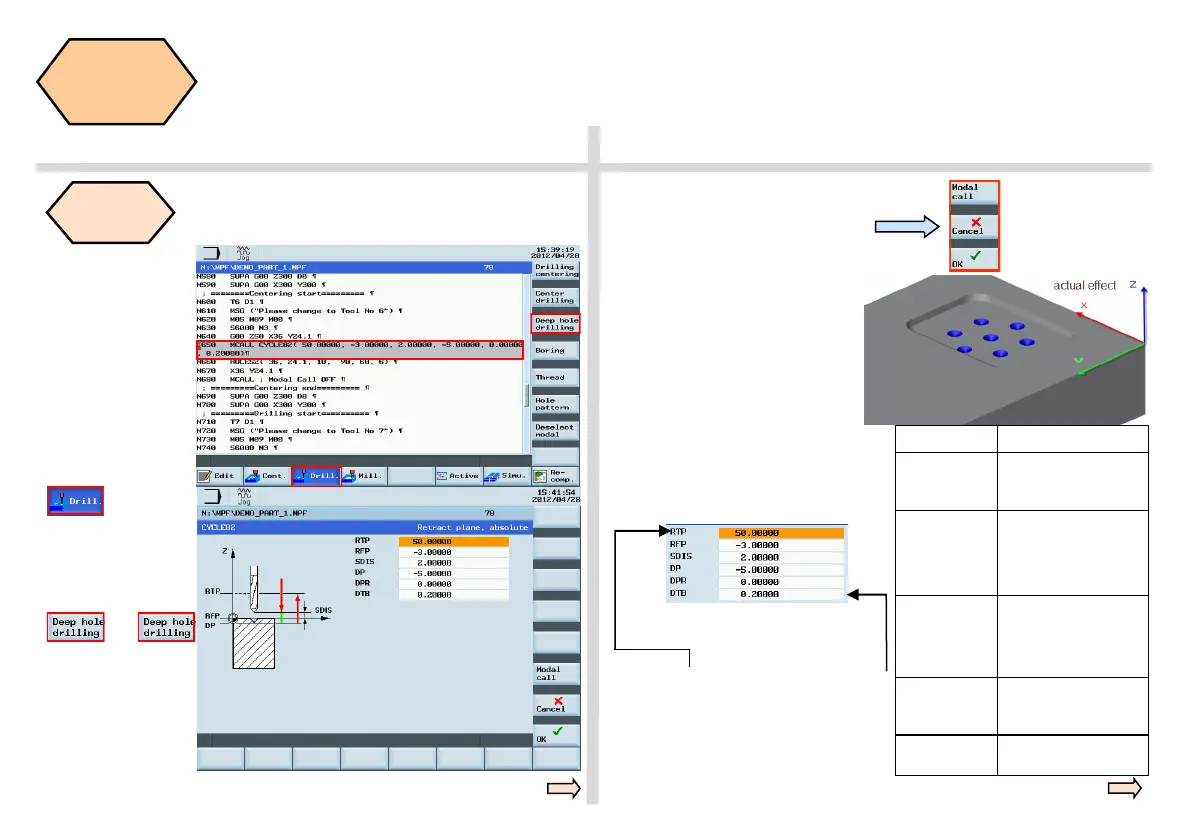

Parameters Meanings

RTP=50 Coordinate value of

turning position is 50

(absolute)

RFP=-3 Coordinate value of hole

edge starting position

under workpiece zero

point surface is 3

(absolute)

SDID=2

(frequently

used values

2~5)

Safety distance, feed

path changes from quick

feed to machine feed 2

mm away from RFP face

DP=-5 Coordinate position of

final drilling depth is -5

(absolute)

DTB=0.2 Delay of 0.2 s at final

drilling depth

The relevant cycle

can now be found

using the vertical

softkey on the

right.

Loading...

Loading...