9

0 - 0.03 mm

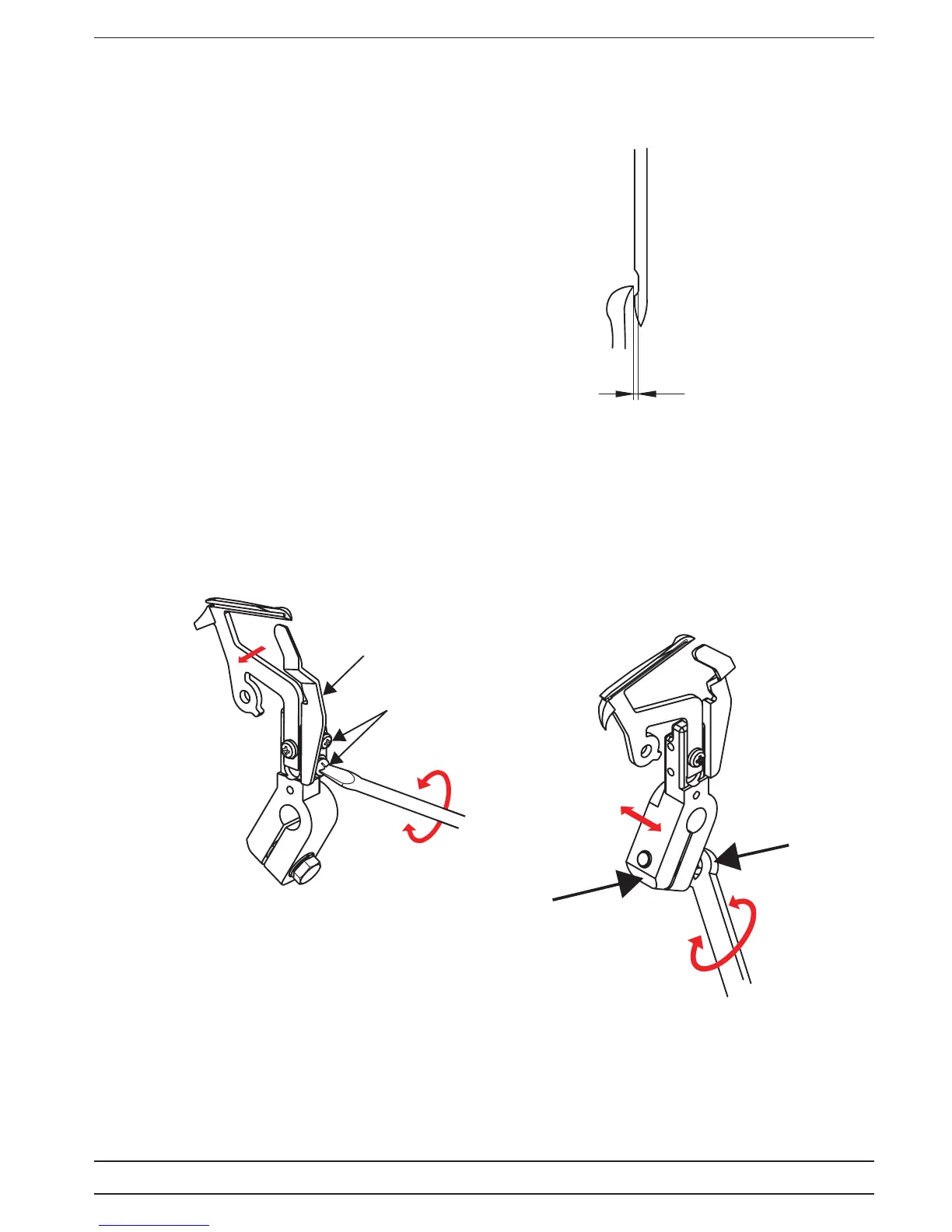

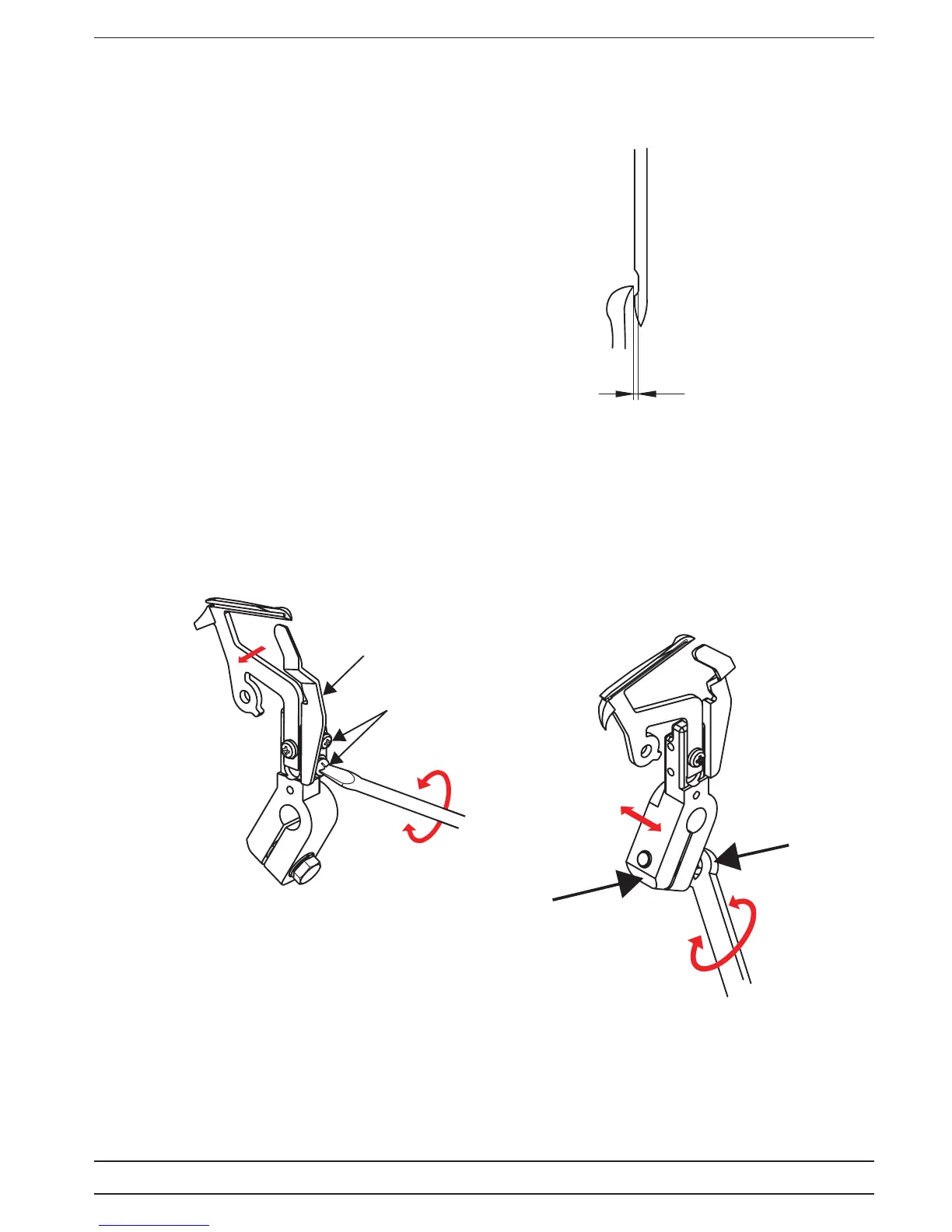

D

E

C

F

1047306-26

6. Looper to needle clearance

Note: A new needle system ELx705 Nm 90 must be used for the following steps.

Check

1. Turn the handwheel in the sewing direction until the looper

point, as it is moving to the right, is positioned exactly in the

scarf of the needle “A”.

2.The looper to needle clearance must be 0 - 0.03 mm.

Setting:

1. Remove the presser foot and the needle plate.

2. Slightly loosen two fastening screws (C) and push the

needle guard (F) slightly toward the front.

3. Turn the handwheel in the normal direction until the looper

point, when moving to the right, is positioned exactly in the

scarf of the needle “A”.

4. Loosen the screw (D) on the looper lever (E).

5. Set the looper to needle clearance by moving the looper lever (E), to the front or to the

back.

6. Tighten screw (D).

7. Re-check the distance between both "A" and "B" needles

8 Re-check the clearance between lower looper an "A" needle.

8. Re-set the "Clearance between lower looper needle guard and "A", "B" needles"

Loading...

Loading...