FLEXIBLE ASSEMBLY SYSTEM FAS200

User Manual for FAS200 - 28 -

This operation begins when the pallet is positioned opposite the fourth module,

held in a determined location by a stopper and a positioner-lifter on the linear

transfer. Confirmation that the pallet is in the correct position is provided by a

microswitch which sends the appropriate signal to the PLC of the fourth module

which in turn sends the signal “start cycle” to the PLC of this third module.

INTEGRAL PARTS:

The third module, like the others, may be divided into a series of manipulators.

Each sub-division has been made by considering it as a set of components

which performs a specific operation within the whole process carried out at the

module.

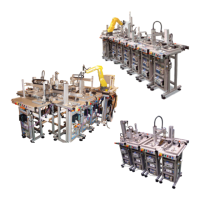

• Bearing feeder:

The feeder which supplies the bearing is of the

gravity feed type, in that the bearings are

stored in a column so that when the bottom

one is removed (the bearing is extracted at the

moment the cycle starts), the next falls into place

under the effect of its own weight and that of the

ones above it.

F

Figure 33: Bearing feeder.

In this case, there is a bearing presence sensor in the form of a microswitch

which allows the PLC to verify that a bearing really

has been extracted following the feeding

procedure. This makes it possible to determine

when the bearings loaded in the feeder have run

out.

Figure 34: Microswitch.

Loading...

Loading...