FLEXIBLE ASSEMBLY SYSTEM FAS200

User Manual for FAS200 - 57 -

The need for appropriate checks to determine which type of cover is to be

assembled at each module cycle means that this module is one of the most

complex in terms of the operations to be carried out. It is also essential that the

module control coordinates part selection operations in accordance with the

commands supplied by the master responsible for production management

in the FAS-200.

This ninth module feeds the cover which is

the closure cap for the turning mechanism,

and verifies its material, color and height.

Then, the next module rejects the cover or

places it onside the housing of the body on

the pallet, depending of the signals “metal

cover”, “plastic cover”, “black cover”, “white

cover”, “tall cover” and “short cover”.

The confirmation of the cover is the correct

one (material, color and height) is got by

some sensors (an inductive detector, a

photoelectric detector and a pneumatic

cylinder with stroke reading) turning on

some internal flags of the PLC, the

previously mentioned signals.

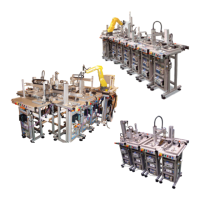

Figure 61: Manipulators of the ninth module.

This operation begins when the pallet is positioned opposite the tenth module,

held in a determined location by a stopper on the linear transfer. Confirmation

that the pallet is in the correct position is provided by a microswitch which sends

the appropriate signal to the PLC of the tenth module which in turn sends the

signal “start cycle” to the PLC of this ninth module.

Loading...

Loading...