FLEXIBLE ASSEMBLY SYSTEM FAS200

User Manual for FAS200 - 64 -

This operation begins when the pallet is positioned opposite the module, held in

a determined location by a stopper on the linear transfer, and when the PLC of

the ninth module sends the signal “end cycle” to the PLC of this tenth module.

The task of placing the cover is performed on the pallet brought by the belt

conveyor and carrying the body-bearing-shaft assembly fed and assembled by

the previous modules. The cover fitting operation requires the pallet is stopped

and retained by a stopper.

INTEGRAL PARTS

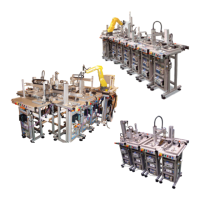

The tenth module, like the others, may be divided into a series of manipulators.

Each sub-division has been made by considering it as a set of components

which performs a specific operation within the whole process carried out at the

module.

• Rejection of incorrect cover:

If the cover reaches the last-but-one index

plate position (on the previous module), and the

various material or height sensors have

indicated that it is not of the material or height

indicated by the main controller in charge of

production of the system FAS200, then it must be

rejected. This operation is effected at this

module by a two-cartesian axes manipulator,

which picks the cover off the index plate and

deposits it on a removal ramp if the corresponding

signal is received.

Figure 69: Rejection manipulator.

The manipulator comprises two pneumatic parallel rod cylinders, at the end of

which is a suction plate with three vacuum-holding cups.

Loading...

Loading...