LECP6-TFM107 Draft

8 CE Directive

The LE series of actuators, motor controllers and teaching box

conform to the EU EMC directive, if they are installed in accordance

with the following instructions.

These components are intended for incorporation into machinery and

assemblies forming part of a larger system.

The CE compliance was achieved when the above three components

were connected as shown in the diagram below.

Please note that the EMC changes according to the configuration of

the customers control panel and the relationship with other electrical

equipment and wiring. Therefore conformity to the EMC directive

cannot be certified for SMC components incorporated into the

customer’s equipment under actual operating conditions. As a result

it is necessary for the customer to verify conformity to the EMC

directive for the machinery and equipment as a whole.

• Machinery parts list

No.

Part name Part no./Material

1 Motor controller LECP6 Series

2 Actuator LE Series

3 Teaching box LEC-T1 Series

4 I/O cable (with shield) LEC-CN5-[]

5 Power supply cable

(with shield)

5 wire with shield

(5 m)

6 Actuator cable LEC-CP-[]

7 P-clip (for shield ground) Metal

8 Programmable controller –

9 Switching power supply –

The LECP6** controller should be mounted in an IP54 rated metal cabinet

for protection from ESD.

The metal cabinet should be grounded with a short grounding cable.

All shielded cables must be grounded inside the cabinet using suitable

metal P-Clip or U-Clip as shown.

The shielded cables are:

• 24 VDC Power cable from power supply to LECP6** series controller

• The Input/output cable from controller to PLC

• Grounding the controller

Please refer to the “Installation” section

8 CE Directive (continued)

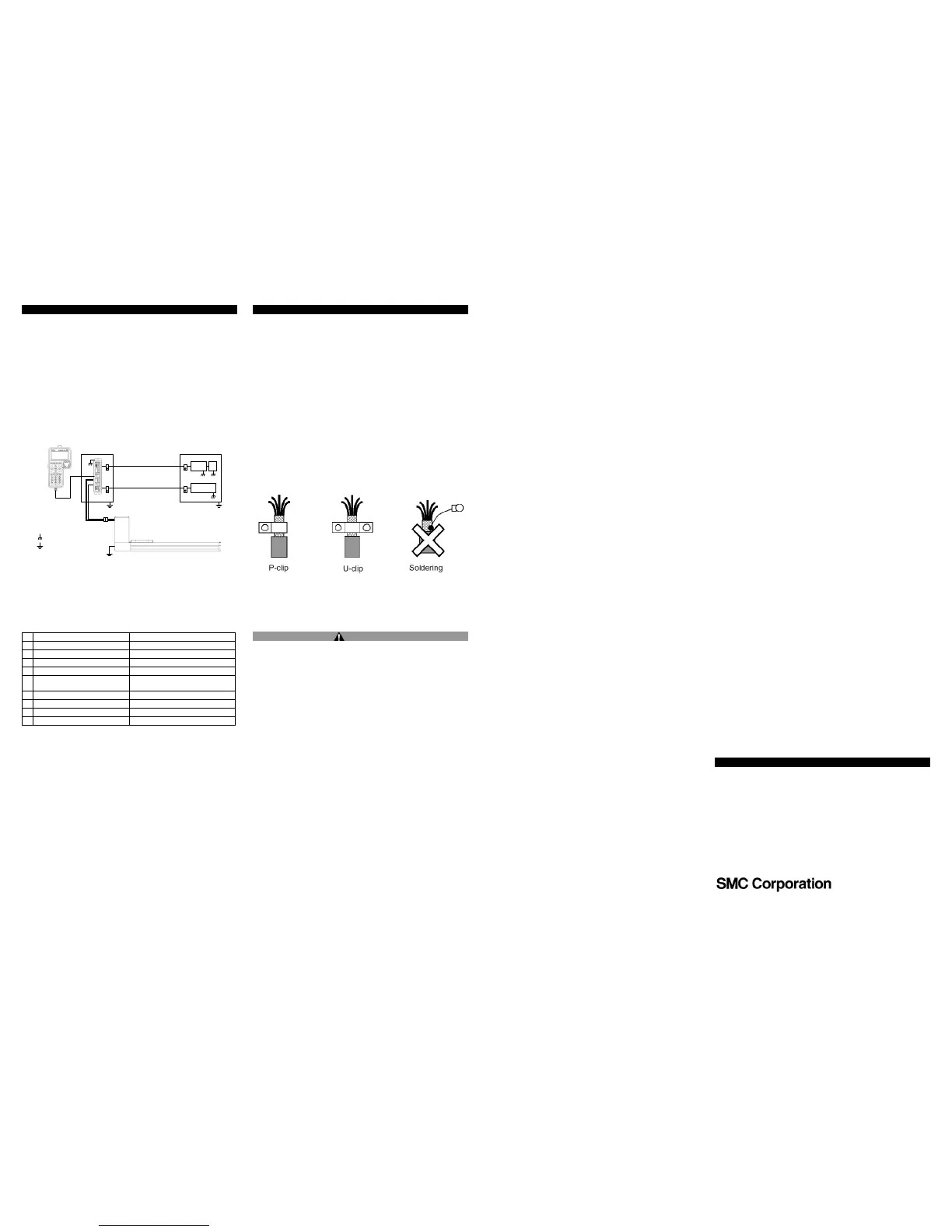

• P-Clip or U-Clip installation

The function of the P-clip or U-clip is to provide a 360° metallic contact

and is a convenient method of ensuring an effective RF ground.

When dealing with EMI issues it is important to know that the DC

connection does not maintain the integrity of an AC high frequency

connection. High frequency bonding typically involves using wide flat

cabling to establish an effective system ground. When applied correctly

the P-clip or the U-clip will provide a high frequency connection.

When installing a P-clip or U-clip (see figure below) install the clips as

close to the cable ends as possible. In order to provide a suitable ground

connection surface, it may be necessary to remove the paint from the

panel or the cabinet, an earth stud or a bus bar are also acceptable.

Remove only the outer vinyl jacket of the braided screened cable (this

allows the cable braid to connect to the P-clip or U clip). Take care not to

damage the braiding. Snap the P-Clip or the U-Clip over the exposed

braiding and adjust for a tight fit. Secure the clip to the designated

ground with a machine screw and lock washer. The use of a brass or

other conductive insert is recommended. Soldering a pigtail to the cable

shield is not a suitable method for providing good RF ground.

• Grounding the actuator

Please refer to the IMM of the actuator being used, for information on

actuator grounding.

Caution

Note: During installation and maintenance protect the LEC controller

from electrostatic discharge (ESD)

Contacts

AUSTRIA

Loading...

Loading...