Piping

■ Piping for Air Pressure Supply and Vacuum Pressure Supply

(1) Preparation before piping

Before piping, perform air blow (flushing) or cleaning to remove any cutting chips, cutting oil,

dust, etc. from the piping.

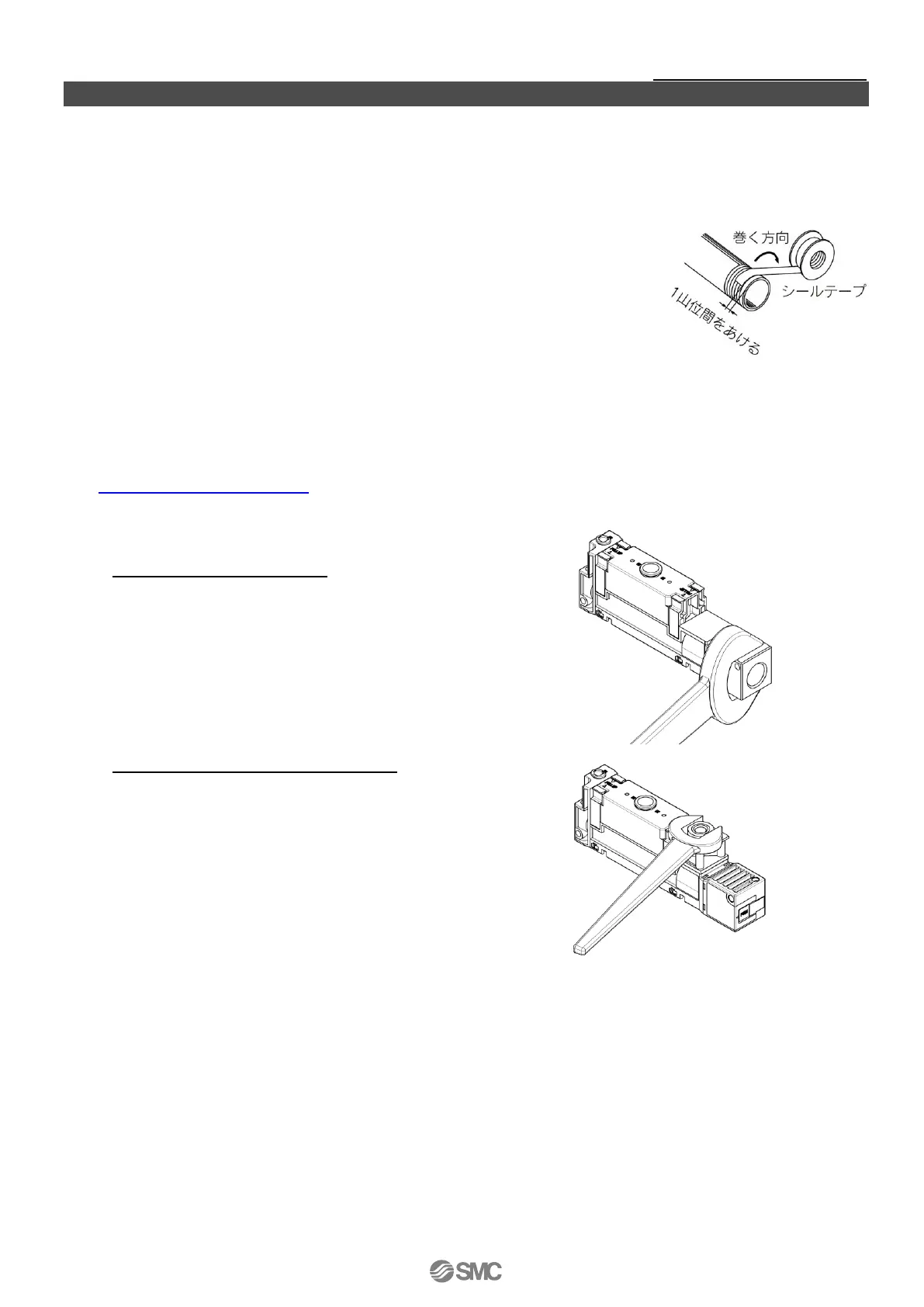

(2) Wrapping of pipe tape

When installing piping or a tube fitting into a port, prevent cutting

chips and sealant material from getting inside the product.

If a sealant tape is used, leave 1 thread exposed at the end of threads.

(3) When connecting tubing, consider factors such as changes in the tubing length due to

pressure, and allow a sufficient margin.

Otherwise, it can damage the fitting and cause the tube to come off. Refer to Fittings & Tubing

Precautions from 1 to 4 shown in Best Pneumatics 6 on SMC’s website (URL

http://www.smcworld.com) for the recommended piping conditions.

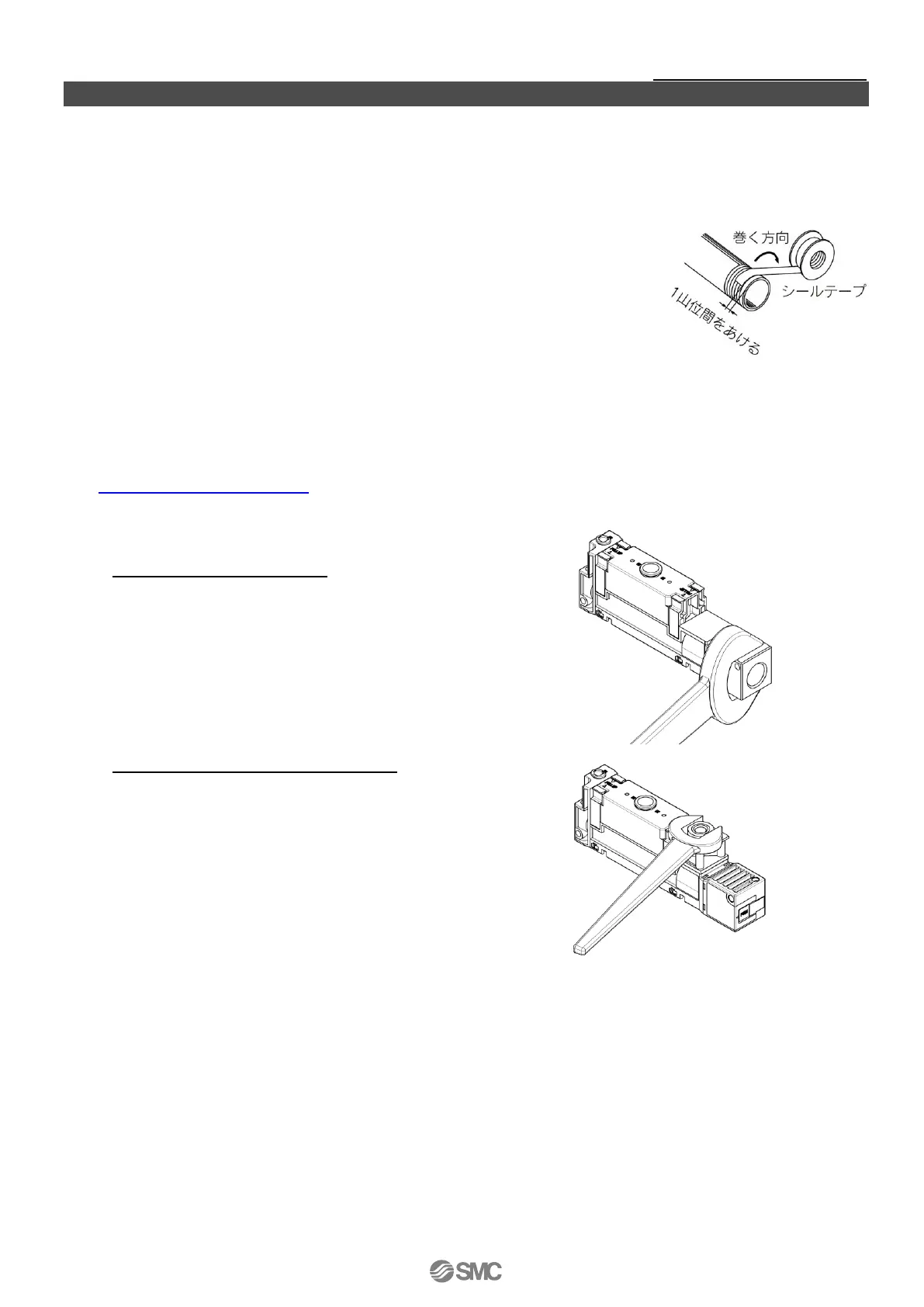

■ Piping to the Exhaust Port, Vacuum Port Adapter

Piping to the Exhaust Port

When mounting or removing the piping to or from

the exhaust port, hold the exhaust block with

a wrench (across the flats 36).

Recommended tightening torque:20 to 25 N·m

The product may break, if it is held by hand.

Piping to the Vacuum Port Adapter

When mounting or removing the fitting,

etc. to or from the vacuum port adapter,

hold the vacuum port adapter with a wrench

(across the flats 19).

Recommended tightening torque:3 to 5 N·m

The product may break, if it is held by hand.

When piping is connected to the exhaust port block and vacuum port adapter, pay attention

that no twisting, tensile, moment loads, vibration or impact should be applied to the piping.

This can cause displacement or damage of the port.

Loading...

Loading...