OPERATION

The main working body of a moving truck is the fork, which relies on a fork to carry the pallet or cargo for

transport and short distance transportation.The expansion of the cylinder is realized by the control of the

operating handle, and the pressure oil is provided by the pumping station.

ELECTRICAL SYSTEM

• Turn the travel switch (2) to "0" position or release the switch to make the truck brake until it stops.

• With the driving switch (2) moving directly from one driving direction to the opposite direction, the vehicle

regenerates the brake until it begins to move in the opposite direction.

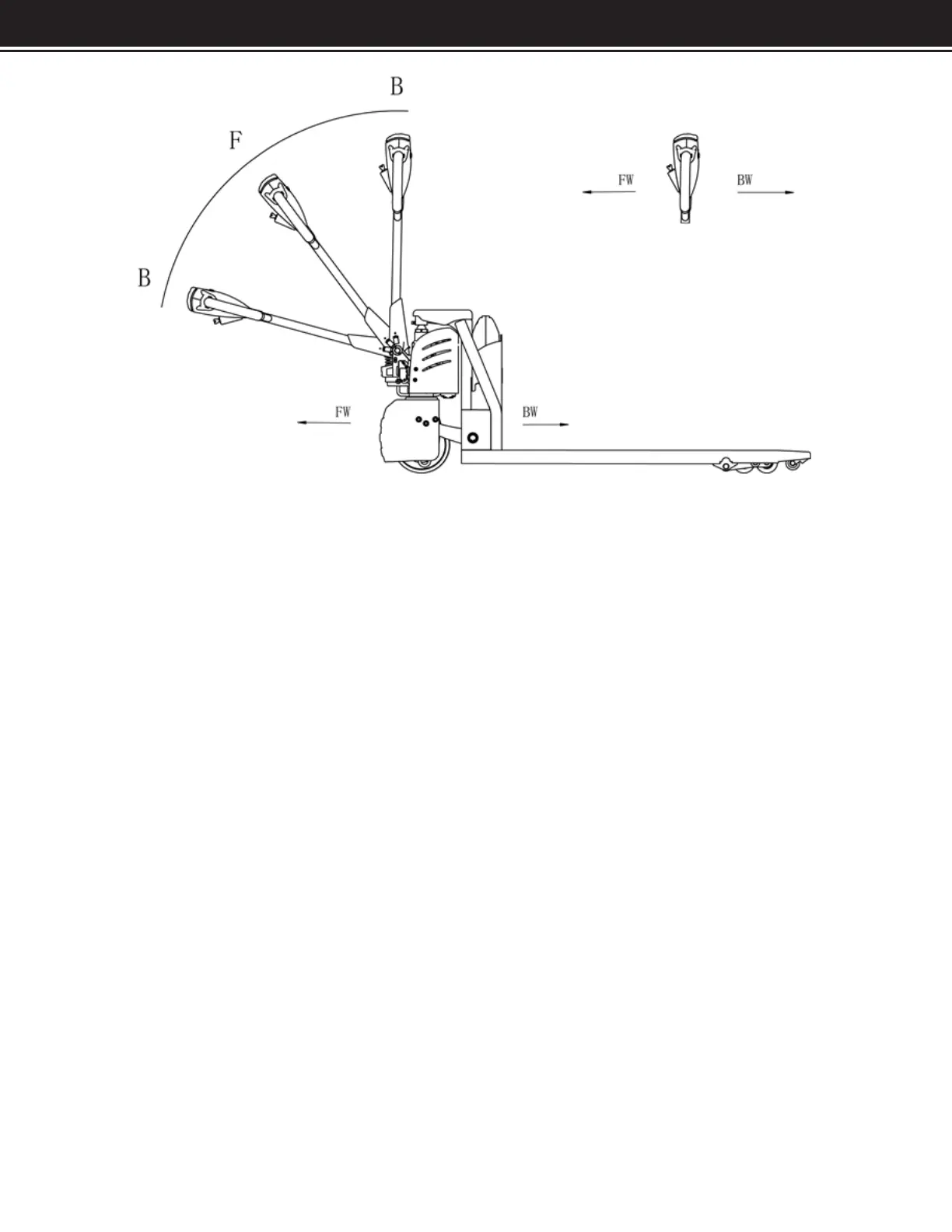

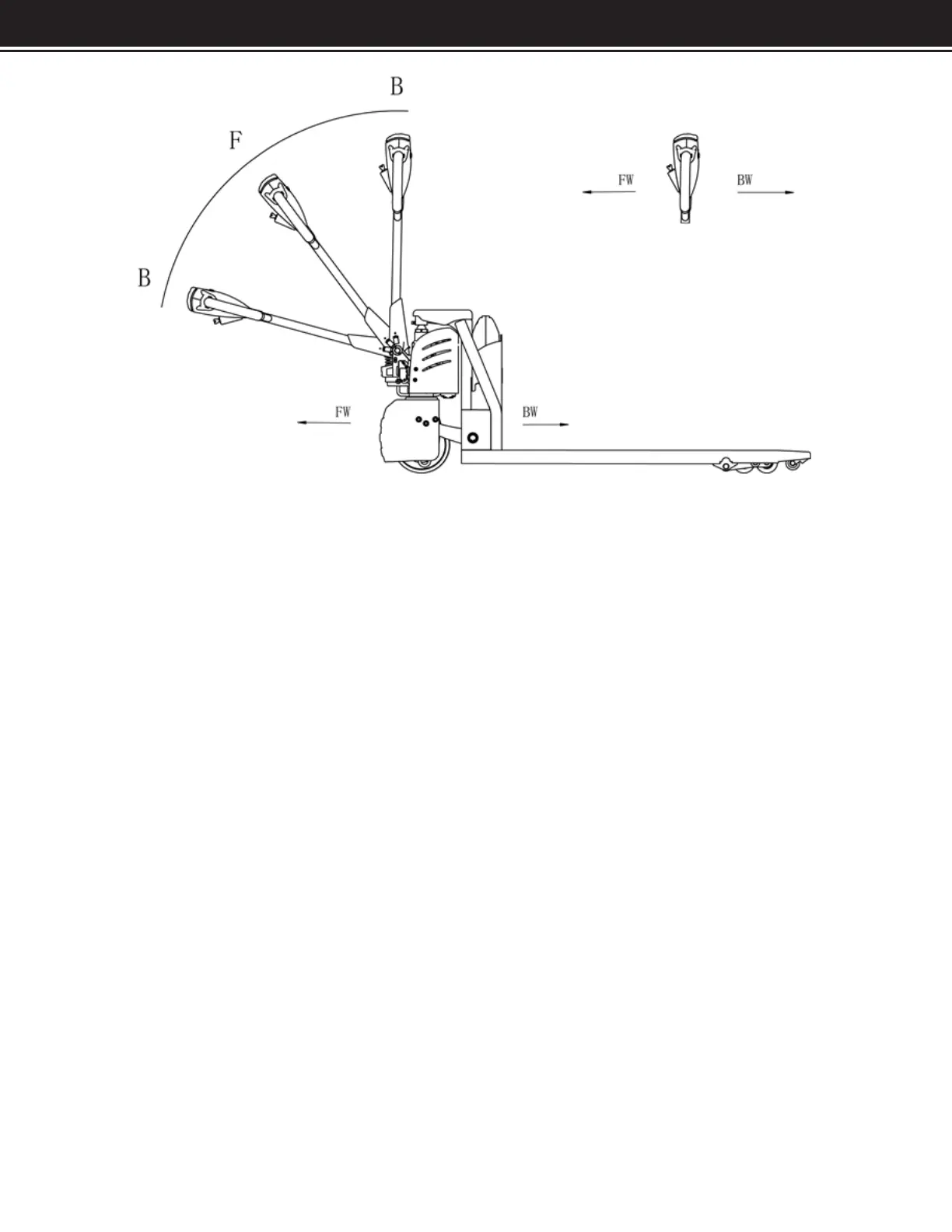

• The handle moves up and down to the braking area (' B ') and the truck brakes. If the handle is released, the

handle automatically moves to the upper braking area (' B ') and the truck start braking until it stops.

• Emergency Reverse button (4) can prevent the operator will be squeezed, when the truck is facing an

obstacle in forward direction. The body touch Emergency reverse button and the truck de-accelerates or

starts to move to (BW) for a distance and then stops. If the handle is in the operating area and the truck is not

moving, please consider that this button is still working.

HYDRAULIC SYSTEM

The oil pump motor drives the gear pump to provide hydraulic power. Lifting oil cylinder is responsible of fork’s

lifting and lowering. The control of the lift oil road is controlled by the buttons on the operating handle. The

lifting action is controlled by a single action oil circuit on the valve block. This model of the hydraulic system

pressure can only be adjusted on the valve block.

10

Loading...

Loading...